-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Simulating a Salt-Cooled Reactor for Safety

By Fatih Sinan Sarikurt, CFD & Thermal Fluids Engineer, Kairos Power, Alameda, U.S.A.

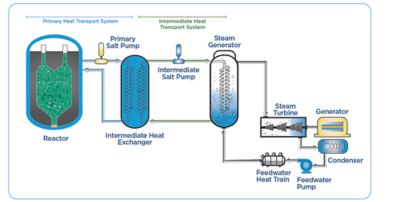

The world increasingly relies on electricity, and nuclear energy is a carbon-free source of power. To improve upon existing technology, Kairos Power uses computational fluid dynamics (CFD) and structural simulation solutions to develop the heat transport system for a low-pressure, high-temperature nuclear power reactor.

As demand for power increases, electricity generated from low-carbon sources is playing a strong role in the move toward global electrification. Thermal power plants working with coal and natural gas offer the best opportunity to be upgraded to eliminate or reduce CO2 and other greenhouse gas emissions. Consumer and industrial companies are seeking to acquire the electricity to power vehicles, and to heat and cool buildings and a wide variety of other systems using small-carbon-footprint sources.

Ansys Fluent enabled the design of the KP-FHR intermediate heat exchanger’s twisted tubes and provided insight into the design of the reactor core.

That is where nuclear energy comes in. Currently representing 20% of electricity generation, nuclear power plants are carbon-free. Nuclear reactors do not produce air pollution or carbon dioxide while operating, so they can help reduce the world’s carbon footprint. New nuclear reactor technology has the potential to make the impact even larger.

Of the planet’s 450 nuclear power reactors, 96% are water-cooled. Most operate at about 315 C and require high pressure to keep the water from vaporizing and losing its heat transfer capacity.

To improve safety, efficiency, sustainability and cost, Kairos Power — which focuses on the integrated design, licensing and demonstration of advanced reactor technology — is developing a unique, fourth-generation advanced nuclear reactor for commercial grid electricity production. The company’s low-pressure, high-temperature Kairos Power Fluoride Salt-Cooled High Temperature Reactor (KP-FHR) system mitigates the risks associated with water-cooled technology and has a near-zero carbon footprint

The KP-FHR leverages tristructural isotropic (TRISO) fuel particles — a uranium kernel with a coating around it — that can withstand temperatures as high as 1,600 C without melting and uses fluoride salt coolant instead of water in its heat exchange process. Because molten salt remains liquid without pressurization between 500 C and 1,400 C, it enables superior heat transfer capability at extreme temperatures. The KP-FHR releases heat into molten salt from spherical fuel pebbles and transfers it to the heat exchanger.

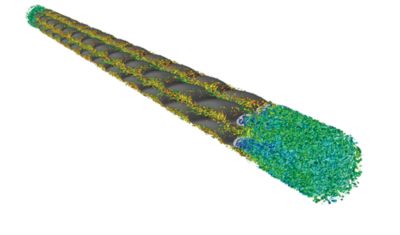

The packed pebble reactor core leverages TRISO fuel particles.

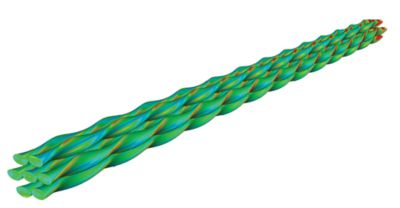

The heat exchanger’s twisted elliptical tube geometries improve heat transfer with a marginal increase in frictional losses, meaning there is lower heat exchanger volume and reduced operational cost.

Kairos Power uses Ansys Fluent to characterize the design for the KP-FHR intermediate heat exchanger. Through simulation, Kairos Power reduced the number of design iterations, lowered costs compared to physical testing and shortened the overall development time.

The company adopted Ansys technology for informing the design of both safety- and non-safety-related systems, because Ansys is committed to the development of software tools, including Fluent and Ansys Mechanical, that follow the ASME’s Nuclear Quality Assurance-1 (NQA-1) requirements as endorsed by the U.S. Nuclear Regulatory Commission (NRC).

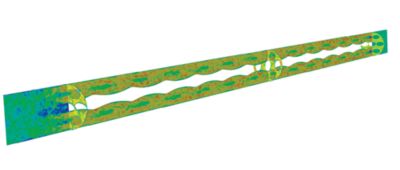

Ansys Fluent simulation showing instantaneous flow velocity

Ansys Fluent simulation showing contours of mean surface heat transfer coefficient

POROUS MEDIA MODELING FOR DIFFICULT CALCULATIONS

Analyzing flow and heat transfer characteristics in a system like the KP-FHR, where molten salt flows through a random-packed pebble-bed reactor core, is difficult. Among other Fluent features, engineers used porous media modeling in initial design iterations for the reactor core, including calculating temperature distribution.

Because of the huge number of pebbles in the core, modeling flow and temperature fields any other way would require an enormous number of calculation cells and unfeasible computational power. By using the porous media modeling capabilities in Fluent, engineers created a local equilibrium model of the full reactor vessel with a reasonable number of mesh cells. As a result, they were able to calculate the temperatures of fuel, molten salt and internal structures at various locations in the reactor core.

SIMULATING PRESSURE DROP, HEAT TRANSFER COEFFICIENTS

To inform the reduced order modeling of the KP-FHR reactor system, engineers were particularly interested in analyzing pressure drop and heat transfer coefficient values in the explicit packed pebble-bed core.

Often, correlations from previous experiments can be used, especially when Reynolds number ranges are similar. In this case, however, heat transfer correlations from gas-cooled reactors could not be used because of the distinct properties of the molten salt, which has high Prandtl numbers. Instead, simulation provided a way for Kairos Power engineers to arrive at the information they needed faster to satisfy the demanding timeline of the agile design process.

A twisted tube heat exchanger provides better heat transfer and costs less to operate.

ONE DESIGN INFLUENCES THE OTHERS

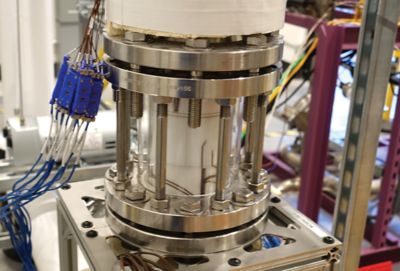

With a design this complicated and so much at stake, Kairos Power also needed a reliable way to test the twisted elliptical tube.

Using Mosaic-enabled meshing technology in Ansys Fluent, engineers created a mesh of a twisted tube bundle and then compared the results against experimental correlations. The parallel meshing process produced a high-quality mesh eight times faster and with less user input compared to other meshing software Kairos Power engineers had used before.

Through simulation, Kairos Power reduced the number of design iterations, lowered costs compared to physical testing and shortened the overall development time.

The pressure drop values derived from the Fluent twisted elliptical tube simulations did not just affect the twisted elliptical tube design; they also drove design requirements for other components, including the pump. In addition, by identifying hot and cold spots in the reactor core, the simulation enabled engineers to improve the integrity of structural materials. Finally, Fluent’s scaling capabilities allowed Kairos Power to conduct rapid iterative testing on smaller-scale geometries, accelerating design evaluations while optimizing the research budget.

Kairos engineers’ ability to gather data via experiments is limited, but with Ansys simulations they can extract detailed, spatially resolved data to better understand local conditions.

FASTER DESIGN, FASTER EVALUATION

The high temperature range of the KP-FHR promises efficiencies; however, it also creates design challenges. Kairos has a design strategy that emphasizes rapid iteration in scaled testing using prototypical and surrogate fluids. Ansys enables the company to accelerate design and understand scaling distortions in our rapid design/build/test iterations, and to extract additional understanding.

Ansys Fluent transient simulation showing contours of velocity magnitude for the twisted tube

Kairos engineers’ ability to gather data via experiments is limited, but with Ansys simulations they can extract detailed, spatially resolved data to better understand local conditions.

Ultimately, Fluent and Mechanical helped engineers understand:

- Effects of geometry and flow conditions on the twisted elliptical tube design

- Hot/cold spots throughout the domain

- Thermal stratification

- Scale-up behavior as the number of twisted elliptical tube bundles increases

- How to model a plant-scale heat exchanger

Kairos Power’s rapid iteration between design, modeling and testing improved risk management capabilities and enabled early identification of high-risk issues.

Although the KP-FHR has not yet reached the commercialization stage, Ansys simulation software accelerated design evaluations, enabled rapid iteration in testing, and helped mitigate technology development risk.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。