-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

A New Kind of Eyes on the Road

Matt Harrison, Director of AI and Safa Salman, Staff Hardware Engineer, Metawave Palo Alto, U.S.A.

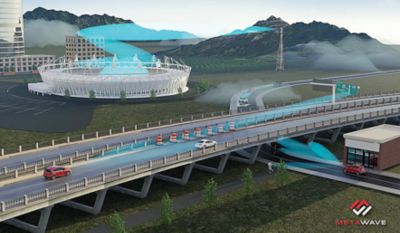

One roadblock to highly automated driving is the need to develop a sensor technology that can sufficiently detect and classify objects — especially ones that are close together — at long distances, during inclement weather, around curves and corners, and in other challenging circumstances. With the help of Ansys HFSS simulation, radar and 5G startup Metawave has built a breakthrough radar platform that overcomes these issues to help fast-track autonomous driving.

In a perfect driving scenario, streets would be free of pedestrians, bicyclists, children playing, animals running free, trash, slick spots, traffic cones and other potential hazards, including careless or distracted motorists. Unfortunately, the real roadway is much more complicated, and today, automakers are building highly automated features that still require a driver-in-the-loop.

How can the car of tomorrow meet today’s safety requirements, as well as expectations for a smooth riding experience? Automakers are determining how to provide highly automated features now, while drivers are still at the wheel, as innovative companies provide the sensors needed to ensure that we are prepared for a future with autonomous vehicles on our freeways, city streets and neighborhood roads. Cameras, lidar, ultrasonic sensors and radar — along with AI — are all being innovated to create a new world of transportation. Sensor technology for self-driving cars is big business, with the market for lidar alone reaching $1 billion in 2019 and the automotive radar market predicted to reach $6.61 billion by 2021.

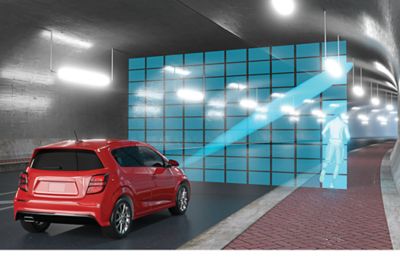

Metawave says SPEKTRA can detect and classify roadway objects up to about 330 meters away, even in conditions that limit human visibility, such as darkness or heavy fog.

Today’s Sensing

The current breed of sensors can fall short. Cameras have very high resolution, but they can only see out about 50 meters. Lidar can see faraway objects, but most of these platforms are expensive and big, and they can’t see in the dark or inclement weather. Today’s digital beamforming radar can see in the dark, but it has trouble distinguishing between objects.

The truth is, all of these sensors are important; they exist for different reasons, and they provide different information so that the vehicle can operate smoothly and safely. But what is the missing sensor today? Metawave thinks it’s long-range analog radar.

Enabling Autonomous Driving

As Metawave set out to build an analog beamforming radar to address the inherent challenges of today’s radar technologies, the company took advantage of Ansys HFSS simulation software — part of the Ansys electromagnetic suite. As a graduate of the Ansys Startup Program, Metawave used the software to help develop its high-performance SPEKTRA radar.

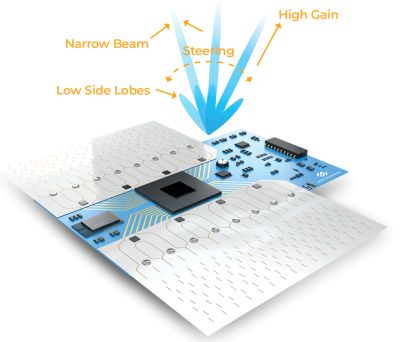

SPEKTRA combines analog beamforming and beamsteering with advanced digital signal processing to illuminate the driving field of view (FoV) and detect all the objects on the roadway in high resolution. Beamforming uses a pencil-like beam with high gain for reaching far distances (up to 330 meters), along with lower side lobes to reduce the probability of false target detection.

By simulating SPEKTRA’s phased array antenna and printed circuit board–type feed network, Metawave predicted the behavior of the beam at all angles and pushed the boundaries of radar specifications.

Beamsteering is used to scan the FoV in milliseconds. Combined, beamforming and beamsteering allow a high-frequency radio signal beam to be shaped and pointed in a specific direction, focusing the radar signal into a narrow beam scanned across the scene. As a result, the SPEKTRA radar enables long-range detection and greater resolution.

Integrated with Metawave’s AWARE artificial intelligence (AI) platform, SPEKTRA quickly classifies objects, even those close to each other. SPEKTRA radar can detect and classify roadway objects up to about 330 meters and pedestrians up to about 200 meters. It can do this just as easily in the dark of night, dense fog, sand storms or heavy rain as it does under clear conditions.

Although Metawave designed SPEKTRA to tackle the difficult, long-range applications associated with highly automated driving, including features like highway pilot, traffic jam pilot and auto emergency braking, it is flexible enough to fit any sensor suite and can also be adapted to operate at shorter ranges.

Pushing the Boundaries of Autonomous Driving

Metawave engineers used Ansys HFSS at the start of the development process and then again to integrate components such as the radome and enclosure. By simulating SPEKTRA’s phased array antenna and printed circuit board (PCB)-type feed network to carry information to the antenna, Metawave predicted the behavior of the beam at all angles and pushed the boundaries of radar specifications, including:

- Narrow beam for high resolution, which allows SPEKTRA to detect adjacent targets at long range

- Low side lobes, to reduce the probability of false detections

- High gain, for target detection at greater distances

- Instantaneous illumination of the field of view to track the direction of all surrounding targets

By using the adaptive meshing and 3D component features in Ansys HFSS, Metawave avoided the risk of under- or over-meshing, which can lead to a loss of accuracy. Ansys’ adaptive meshing also helped preserve subcomponents’ parameters within the larger model.

Because Ansys HFSS includes multiple solvers within the same user interface and has a streamlined simulation model setup process, engineers could quickly begin the design process, which contributed to a shorter development cycle and lower costs.

Integrated with Metawave’s AWARE artificial intelligence platform, SPEKTRA classifies objects, even those close to each other, at long range with high angular resolutions.

Design for Manufacturability

Whether a product is as simple as a wooden dowel or as complex as AI-integrated radar, how it will be manufactured is an important consideration throughout the product design and development process. Ansys HFSS enabled Metawave engineers to quickly weigh the advantages and disadvantages of multiple designs, envision the final product, and verify their hypotheses about performance and manufacturability.

Specifically, Metawave engineers wanted to be certain that the prototype design could withstand the variations required by PCB manufacturing tolerances and still deliver optimum performance. Adding the Ansys Optimetrics toolbox to Ansys HFSS provided statistical capabilities that enabled them to gauge the feasibility, flexibility and robustness of the proposed prototype.

The Road to Autonomous Driving

Metawave began delivering its first-phase proof-of-concept product to leading automakers and Tier 1 transportation providers in 2019. Its advanced beamsteering capabilities are designed to help the industry move from driver-assisted automobiles to fully autonomous, driverless cars, and to do it safely, regardless of what else is on the road.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。