-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

In recent years, biomedical engineering has made remarkable strides in developing treatments for eye conditions that once caused millions to suffer from impaired vision or blindness. Groundbreaking innovations — such as polymeric intraocular lenses (IOLs) used to replace cataract-clouded natural lenses — have revolutionized vision restoration procedures. LASIK surgery has become a widely recognized method for correcting common refractive errors like near sightedness, far sightedness, and astigmatism, while advancements in surgical techniques targeting retina issues and managing conditions like glaucoma have significantly improved patient outcomes. Additionally, noninvasive alternatives such as contact lenses, eye drops, and dietary supplements have advanced and benefited from biomedical research.

At the forefront of these advancements is Alcon, the global eye care leader renowned for its innovative eyecare solutions, headquartered in Geneva, Switzerland. Alcon develops advanced instrumentation for diagnosis and surgery in its surgical division, as well as consumer products in its vision care division. Both support the company’s goal of helping people worldwide “See Brilliantly.”

“Alcon is dedicated to providing long-term value for patients by delivering cutting-edge innovation and breakthrough technology, transforming the way we treat eye diseases and eye conditions,” says Sonalee Tambat, senior director and head of modeling and simulation in Alcon’s research and development (R&D) organization.

“To uphold its leadership position, Alcon continuously seeks to pioneer next-generation products and processes to improve patient outcomes and get these solutions to market as fast as possible.” Engineering simulation software from Ansys is helping them in this effort.

Simulation Shortens the Development Cycle

Drawing upon her extensive academic background in mechanical engineering and over 25 years of experience in modeling and simulation, Tambat has been instrumental in leading the company’s modeling and simulation group for the past eight years. Her expertise enables her team to effectively leverage modeling and simulation to expedite product development and time-to-market.

"By integrating simulation at the inception of the design cycle and optimizing virtually assessed designs, we've reduced the number of prototypes and in some cases eliminated an entire build phase."

— Sonalee Tambat, Senior Director of Research and Development, Alcon

“A couple years ago, we launched a drive to fast-track digital transformation at Alcon,” she explains. “As a crucial aspect of this endeavor, we broadened the scope of modeling and simulation across our entire portfolio of products. Our team has tripled in size and we’ve been rolling out customized simulations to global R&D teams working on surgical consoles (cataract, vitreoretinal, and refractive), diagnostics and visualization tools, consumables, intraocular lenses, contact lenses, and a range of ocular drug therapies.”

The company invested in its infrastructure, deploying a high-performance computing (HPC) system with global access, as well as cloud computing and cloud bursting for problems that need large scale-up in central processing units (CPUs).

Through digital integration, Tambat and her group have reduced the development cycle timeline to just a few months for many products. They achieved this by simultaneously modeling multiple designs, materials, and load conditions and streamlining workflows to optimize and achieve desired safety and efficacy requirements. This not only accelerates development time and enhances products but also produces cost savings.

"By integrating simulation at the inception of the design cycle and optimizing virtually assessed designs, we've reduced the number of prototypes and in some cases eliminated an entire build phase. Simulation provides comprehensive answers upfront, enabling us to streamline the process. Additionally, we're now assessing product concepts during the ideation phase, allowing us to swiftly and efficiently halt projects early on if needed, saving valuable time and resources."

Multiphysics Solutions Are Required

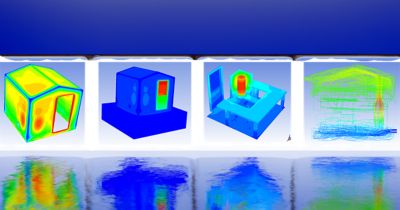

Given the diverse range of products within Alcon’s portfolio, which includes large electro-mechanical surgical consoles, intraocular lenses, contact lenses and ocular drugs, the demand for multiphysics solvers and integration platforms is paramount.

“We have implemented several Ansys modeling and simulation platforms, helping us build an integrated approach, optimize results, and efficiently manage, secure, and store simulation data,” says Tambat.

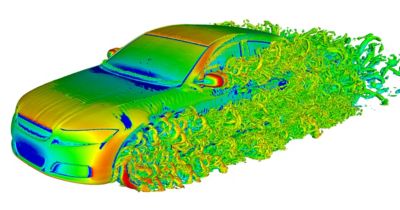

During most eye surgeries, doctors must ensure that the intraocular pressure of the eye is maintained. Alcon engineers can now model this pressure in advance. Similarly, fluid-structure interaction simulation is extremely helpful for developing tools for surgeries done on the retina, which involve extremely small instruments that are used to make an incision, control a laser beam, or other tasks that require careful precision. With computational fluid dynamics, engineers can understand the flow field surrounding the tip of the instrument, which is critical for surgeons to determine how close the device can get to the back of the eye without damaging the retina.

Alcon used Ansys Fluent to calculate the flow field effects of its dual action HyperVit® vitreous cutter probe.

Balancing the Scales

In addition to her dedication to advancing simulation technologies, Tambat is equally passionate about promoting diversity and inclusion within the engineering field. Drawing upon her own experiences as a trailblazer in a male-dominated industry, Tambat actively mentors young engineers and champions diversity initiatives within Alcon and beyond. She believes that fostering a diverse and inclusive workforce not only enhances creativity and innovation but also ensures that the engineering profession reflects the diverse communities it serves.

Simulation Is Evolving

As emerging technology demands more sophisticated engineering each day, Tambat emphasizes the potential benefits of evolving digital capabilities product development. "While modeling and simulation have long been present in various industries, what's particularly promising now is the significant advancements in computing power and artificial intelligence technologies. Moreover, healthcare regulatory bodies are establishing pathways to utilize computational modeling and simulation to validate medical device claims, facilitating the feasibility of swift development and delivery of new technologies for enhanced patient care," she explains. "This presents a pivotal moment for healthcare companies to embrace these technologies, gaining a competitive edge, advancing products, and accelerating innovation."

The field of biomedical engineering is experiencing a transformative period, driven by innovations in simulation technologies. With a steadfast commitment to innovation, companies like Alcon are poised to lead the way in delivering groundbreaking solutions that enhance the lives of millions worldwide.

Learn more about how Ansys can help you with your healthcare innovations.

Digital Twin of the Eye

As a global leader in ophthalmic healthcare, Alcon is continuously striving to use new technologies to drive breakthrough innovation and champion progress. One such initiative they have embarked on is the development of a digital twin of the eye — a modeling and simulation-driven research and development project aimed at building patient-specific computational models of the human eye.

“These models will enable accurate modeling of key aspects of ocular physiology pertaining to the interaction with our devices and therapies in order to further improve the outcome and impact on patients,” says Tambat.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.