-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

May 2021

The Sky’s the Limit

By Douglas Campbell, Technical Director, Electroflight, Gloucestershire, UK

Together, Rolls-Royce and Electroflight are ushering in the third age of aviation, with an all-electric aircraft capable of speeds exceeding 300 mph. A primary challenge is optimizing the 1,047-pound (475 kg) battery pack for structural strength, thermal management and other critical performance criteria. As the team raced to introduce the world’s fastest zero-emissions aircraft, multiphysics simulation, via Ansys, played a crucial role by accelerating battery development and verification.

Rolls-Royce is an aviation pioneer, but the company is focused on the future with an innovative all-electric aircraft. If propeller planes and jets represented the first two ages of aviation, then the third age is certainly focused on sustainable design and zero emissions. Developed as part of Rolls-Royce’s ACCEL initiative ― which stands for Accelerating the Electrification of Flight ― later this year, the aircraft will attempt to shatter the existing 210-mph speed record for an all-electric design. The airframe has already reached speeds of over 300 mph, fitted with a traditional internal combustion engine, so the ACCEL team has high hopes. Just as impressive as the aircraft’s speed is its range. It is capable of making the 200-mile trip from London to Paris on a single battery charge. In addition, a further objective for both the Rolls-Royce and Electroflight teams was to track and document the sustainability for the overall project, which they are proud to have offset, to make the project net zero emissions.

“A Battery With Wings”

Energy-storage performance at this level requires novel engineering approaches and revolutionary battery design. Instead of relying on in-house resources, Rolls-Royce turned to Electroflight, a Gloucestershire, UK, startup that develops high reliability energy storage solutions for aerospace electrification applications.

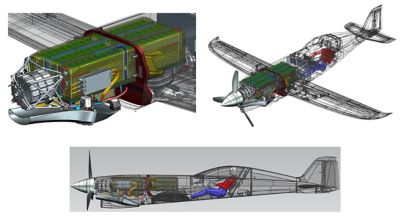

The resulting lithium-ion battery pack incorporates three separate battery assemblies that provide electricity to three high-power electric motors, developed by Oxford-based YASA, a manufacturer of lightweight electric motors and controllers. Based on a proprietary axial-flux design, YASA has been able to deliver a small, lightweight engine configuration that produces more than 500 hp, to support the aircraft’s record-breaking speeds.

While a lightweight engine design may be achievable, even the most power-dense lithium-ion batteries are ― by necessity ― heavy. With more than 6,000 battery cells and an impressive 90% energy efficiency, the battery assembly, designed by Electroflight, produces enough energy to power 250 homes. It also weighs in at 1,047 pounds (475 kg) and commands a great deal of space in the aircraft’s fuselage ― leading some observers to call the aircraft “a battery with wings.”

The battery’s size and weight might be viewed as disadvantages, but Rolls-Royce and Electroflight capitalized on these features by leveraging the battery pack as a key structural element for the one-seater aircraft. This meant the airframe and the battery pack had to be optimized simultaneously to ensure that both elements were integrated to balance energy and propulsion with lift.

Due to its size and weight, the battery assembly functions as a critical structural element in the one-seater aircraft’s relatively small fuselage. That means balancing energy performance with mechanical considerations such as stiffness and resonance, along with sustainability.

“Engineering simulation helped the Electroflight team address three critical issues: materials selection, structural integrity and balanced cooling.”

Another potential downside of the battery pack? The well-documented thermal effects of lithium-ion batteries. To manage the battery packs’ natural propensity to generate heat, Electroflight engineers designed an innovative cooling system that pumps a liquid coolant mixture, composed of water and glycol, through plates between the batteries. Thermal loads are managed as the lithium-ion cells contact the cooling plate, even during the high-power demands of the aircraft performance.

Electroflight’s advanced battery management system gathers thousands of data points per second, providing the pilots with the information needed to extract maximum performance from the battery system when making record attempts. With safety in mind, the Electroflight team engineered the aircraft to land safely with just a single battery pack in operation.

Design Acceleration via Simulation

To model and solve many of the advanced challenges involved in the battery assembly’s design, Electroflight relied on a suite of Ansys simulation solutions, including Ansys Mechanical, Ansys Discovery, Ansys Fluent and Ansys Granta Materials Selector. Engineering simulation helped the Electroflight team address three critical issues: materials selection, structural integrity and balanced cooling.

With the battery pack’s sheer size, relative to the aircraft itself, Electroflight concluded that the pack needed to be a structural member for the small craft, transferring flight loads from the power system to the airframe throughout the aircraft operating and performance cycles. Fulfilling this function required careful analysis and optimization of the battery assembly design. The team wanted to minimize weight, while also ensuring both effective transfer of the flight loads and avoiding vibration modes that may align with any of the system operational frequencies.

Supporting the Electroflight team, Ansys provides full structural and frequency analysis of the battery assembly using Ansys Mechanical. This led to various adjustments to the assembly design, notably the design of new clamps to adjust the stiffness of the full assembly, avoiding resonant frequencies aligned with the propellor operating frequencies.

The individual battery cells are mounted in a compact, back-to-back arrangement located on a polymer mounting plate. The 3D printed frame material originally intended for use was found to have reduced stiffness properties as temperatures increased. Electroflight needed to select a material with a glass transition temperature that was greater than the battery operating temperature, which was a difficult challenge. The team used Granta to down-select materials based on specific requirements. Using Ansys Mechanical and Granta, a 30% glass fiber-filled polycarbonate was identified to be the optimal material. Simulation helped the team meet this difficult material challenge during the design phase.

Optimization Keeps It Cool

Because thermal load is a central concern for lithium-ion batteries, Electroflight engineers leveraged Discovery and Fluent to model the battery cooling system and study the thermal performance for the full battery assembly in real-world operation conditions. The team applied adjoint solution methods in Fluent, which were developed specifically for confined inner flows, to characterize the battery’s innovative cooling system performance. The software automatically explored the operating envelope for a given design, morphing the arrangement to a more-optimal shape, guiding the Electroflight team to an optimized design. Because adjoint simulation provided a roadmap showing which regions of the battery were most sensitive to overheating, developers could focus their efforts accordingly.

Together, the Ansys solutions helped the Electroflight team understand a host of sophisticated issues ―from sustainability and manufacturability, to operating limitations ― and optimize the battery design accordingly. The team was under significant time and cost pressures to meet the milestones associated with the recent test flights, and simulation via Ansys helped solve key engineering challenges rapidly and effectively. Ansys not only helped Electroflight verify the battery pack’s final design prior to the test flights, but answer a number of incredibly complex questions on the way there.

Sustainability Takes Flight

As the global aerospace industry looks ahead, clearly any new aircraft designs must be as carbon-neutral as possible. This creates an entirely new set of challenges for engineering teams, from materials selection to the many facets of energy production and efficiency. Granta tools were able to support this sustainability effort, developing new processing and approaches to fully understand and minimize the project environmental footprint.

Backed by Rolls-Royce’s tradition of aviation leadership and Electroflight’s unique expertise in battery systems ― and armed with best-in-class tools from Ansys ― the Electroflight team is successfully taking on those challenges. With a series of test flights now completed, the partners’ confidence in the future of sustainable aviation is soaring.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。