-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

July 2021

Democratization of Simulation Advances Electrification

By Pierre Millithaler, E-machine simulations (FE) and method development, Schaeffler Automotive Buehl GmbH & Co. KG

What if you deployed a time- and money-saving software application, but people in your company were reluctant to use it because they felt they lacked the necessary expertise?

As technology becomes more complex, this scenario is unfolding in businesses worldwide. In-depth understanding of design simulation software, for example, is often housed in a single department or belongs only to one or two experts, and convincing others to use new platforms can be a tough sell. Even engineers and designers experienced with other sophisticated programs might push back, preferring to work only with the technology they know best.

But it isn’t necessary to be an authority on the underlying technology to take advantage of the benefits that simulation software offers. That’s what democratization is about: making software accessible in such a way that all users can run it successfully without deep knowledge.

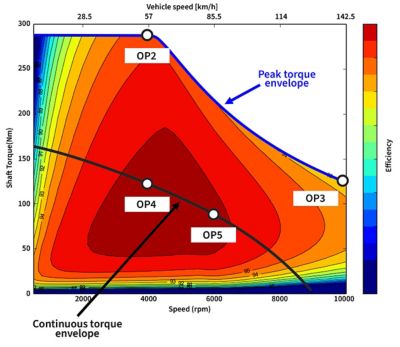

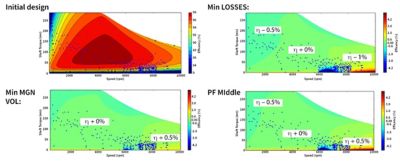

Efficiency map with peak and continuous torque speed requirement

10x More Simulations In Less Time

Schaeffler Group designs advanced systems and components for the automotive industry, including powertrains for electric and hybrid cars. A recent democratization effort by the e-machine Engineering Methods & Simulation team — which supports other Schaeffler departments during new tool deployment — centered on creating a computationally efficient workflow that will enable multiphysics, multi-objective design optimization of the electric machine.

Specifically, the group coupled Ansys Motor-CAD, the leading electric motor design software, with Ansys optiSLang, a platform for process integration and variation analysis. The result was a ready-to-use, duty-cycle–based optimization methodology that will help product designers identify the relationships between the e-machine’s behavior and specific geometrical parameters under real-world conditions

Now, Schaeffler designers and engineers enterprise-wide have a better design-to-validation workflow for electric machines that should reduce reliance on expensive physical prototyping. A meta-model enables a substantial increase in the number of optimization iterations that can be performed, in a fraction of the time required when performing simulations on a finite-element model directly. In an era of energy transition where electrification initiatives are on the rise, and demand for powerful, yet affordable, e-machines is growing alongside them, this will enable Schaeffler to satisfy customer demand faster and better than ever.

Now, Schaeffler designers and engineers enterprise-wide have a better design-to-validation workflow for electric machines that should reduce reliance on expensive physical prototypings.

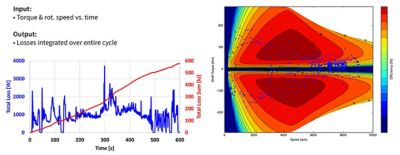

Drive cycle efficiency simulation

Overcoming Barriers to Software Adoption

Schaeffler helps shape mobility for tomorrow. Their products represent a staggering array of processes and disciplines: different aspects of physics, various thermal states, mechanical engineering and electrical engineering, among many others. With the ability of Motor-CAD to produce multiphysics simulations across the full-torque operating range, it is easy to see how the software could fit into the Schaeffler toolkit. In particular, it would allow designers who have expertise in one area — electromagnetics, for example — to performance-map the entire electrical and thermal behavior of electric machine designs without having to acquire additional knowledge.

Among other activities, the Schaeffler simulation department develops standalone tools and workflows that help acquisition teams quickly perform calculations and display specific results. They are also involved in evaluating the potential of existing software and promoting it within the company.

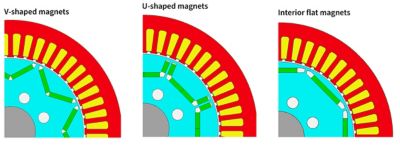

A few years ago, they turned their attention to Motor-CAD. Since evaluating its potential and promoting its use within the company, the number of users within Schaeffler has been increasing. Part of Motor-CAD’s popularity within the company can be attributed to a meta-model–based approach developed by Schaeffler simulation engineers that coupled Motor-CAD and optiSLang to optimize the placement of magnets within an electric drive in the early design phase. Magnets help determine the mechanical power within the drive, so optimizing their volume, shape and other variables serves two purposes. For one, magnets are extremely expensive; using the smallest magnets that meet performance requirements helps reduce overall cost of the electric machine. In addition, geometry optimization helps to minimize performance-altering iron, magnet, and AC or DC winding losses in the electric drive’s rotor and stators during specific drive cycles.

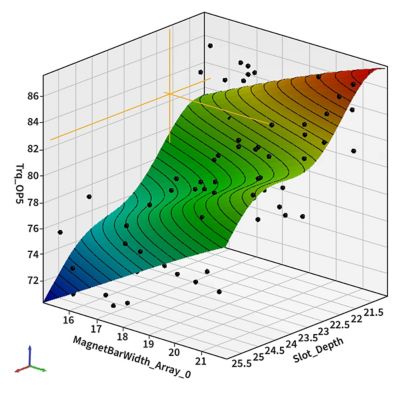

Meta-model visualization of the relationship between two geometry parameters and the continuous torque

Evaluating 100 Different Geometries

Regardless of the algorithms engineers choose, running an optimization involves multiple iterations, and that can take considerable computational time. It’s not unusual for a single finite-element model simulation to take as long as 35 minutes.

To generate results far faster, Schaeffler computed a meta-model in optiSLang then used the software to also run the optimization. That enabled them to run thousands of optimization iterations within minutes.

Schaeffler simulated 100 different geometries in all, evaluating the effect of each design variable, including magnet thickness, at every operating point. The meta-model also accounted for total loss of energy over a given duty cycle, one of the optimization objectives. Using one of the duty cycles embedded in Motor-CAD, Schaeffler’s simulation engineers were also able to assess integrated heat losses over the entire duty cycle.

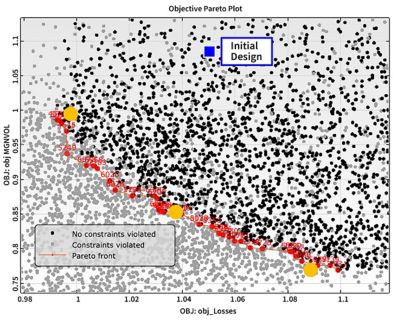

Pareto front, multiple optimal design concepts demonstrating a trade-off between e-machine cost and drive cycle efficiency

The Confidence To Do More, Including Satisfying Customers

During pre-processing, the goal was to define the relationship between shaft torque and rotor speed as design variables (input values or parameters) changed during different duty cycles and during peak or continuous operation.

Schaeffler then used Motor-CAD to model changes in torque at defined operating points against changes in various input parameters: Slot depth, magnet thickness and width, bridge thickness, magnet array angle, and pole arc. Using one of the duty cycles embedded in Motor-CAD, Schaeffler’s simulation engineers were also able to assess integrated losses, including those in the form of heat, over the entire duty cycle. Because customers will expect each of the operating points to deliver at least a certain value of torque, the input parameters provided constraints for the optimizer.

The result, a combination of specific magnet dimensions, represented a 23% improvement in magnet volume compared to the initial design.

At this point, Schaeffler simulations engineers analyzed the relationships between input and output values in optiSLang. Because the simulation software allowed them to generate meta-models with accuracy greater than 95%, Schaeffler had the confidence to compute all the optimization samples for the required algorithms, and to do it without having to repeat any simulations in Motor-CAD.

The simulations group also verified the best magnet design to fulfill performance requirements while minimizing sum total losses and magnet volume. The result, a combination of specific magnet dimensions, represented a 23% improvement in magnet volume compared to the initial design.

In the end, Schaeffler’s work will translate directly into greater customer satisfaction: When an automotive manufacturer requests optimization of a particular operating parameter, Schaeffler can deliver the most promising concept faster than ever.

Selection between different rotor concepts for the same requirements, based on the same optimization workflow

Staying Up To Speed

By coupling front-loading methodologies, Schaeffler created an efficient and flexible tool that enables product designers and engineers to use the same optimization workflow for any electric machine concept — and to have results in minutes. Instead of it taking 50 hours to simulate 100 samples using FEA, the meta-model–based optimization can simulate 10,000 samples within minutes.

The meta-model also eliminates the usual steep learning curve associated with new software, meaning it is helping Schaeffler engineers and designers be more productive right away — and stay up to speed with their automotive customers.

Comparative efficiency map between different optimal design concepts

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。