ケーススタディ

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

「シミュレーションの投資収益率は、プロジェクトごとに異なり、複雑さも異なるため、具体的な数値をあげるのは難しいですが、市場投入までの時間は70%程度短縮され、コストは40%程度削減できると言えるでしょう。」

— Vittorio Cuoco氏(Ampleon社、シニアプリンシパルエンジニア)

オランダの半導体メーカーであるAmpleon社は、60年近くにわたり、より複雑になり、小型化が進む高周波(RF)電力製品を専門に開発してきました。同社は、個別素子、モノリシックマイクロ波集積回路(MMIC: Monolithic Microwave Integrated Circuit)、横方向拡散型MOS(LDMOS: Laterally Diffused Metal-Oxide Semiconductor)テクノロジー、窒化ガリウム(GaN)デバイスなどの革新的なRFソリューションを通じて社会を発展させることを目標として掲げています。

課題

放送分野の数十メガヘルツから、4Gおよび5Gインフラストラクチャ市場向けの数ギガヘルツまで、さまざまな用途に応じて、周波数は多岐にわたります。また、用途に応じて、出力レベルは数ワットから数キロワットまで対応しています。

このような電力レベルを達成するために、複数の大型ダイが単一パッケージに集積されます。ダイは、単一のトランジスタから一体型MMIC増幅器までさまざまです。これらのダイは、パッケージに含まれている大型MOSコンデンサなど、他のコンポーネントとともに集積されます。これらのコンポーネントの目的は、パッケージ内でインピーダンス変換および整合をもたらすことです。ダイと追加コンポーネントは、ボンディングワイヤを介して接続されますが、これらのワイヤは、ダイをパッケージリード線(つまり、外部部品)に接続するためにも使用されます。

ボンディングワイヤは、接続のためだけでなく、インピーダンス変換および整合の一環となる設計要素です。そのため、ワイヤのマルチフィジックス挙動と、ダイやパッケージリード線との相互作用を正確に予測することは、デバイス性能を最適化する上で重要な課題となります。

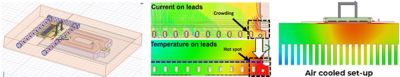

さらに、小型化を目指すことから、限られたスペースに多数のコンポーネントを実装する必要があり、温度も上昇します。高温とそれに関連する機械的応力レベルを信頼性限界内に抑えることも大きな課題です。

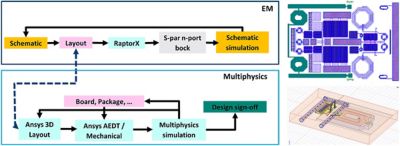

Ampleon社の電磁界およびマルチフィジックス設計フローでは、回路図レベルで一次シミュレーションを実行し、作成されたレイアウトをAnsys RaptorX™でシミュレーションすることで、新しい回路シミュレーション用のSパラメータブロックが作成される。レイアウトは、Ansys Mechanical™でシステムレベルマルチフィジックスシミュレーションを実行するために、Ansys Electronics Desktop™にインポートされる。

エンジニアリングソリューション

Ampleon社では、Ansys Electronics Desktopプラットフォームを活用して電磁界、熱、および機械シミュレーションを実行し、実際の動作条件下でパッケージ、集積デバイス、さらには完全なシステムのEM性能を解析して最適化しています。また、このプラットフォームは電気-熱-機械の統合されたマルチフィジックスフローにも使用されます。その場合は、電磁界ソルバーによって計算された散逸が、熱ソルバーの荷重として使用され、それらの結果がMechanicalソルバーの荷重として使用されます。電磁界回路コシミュレーションは、現実的な荷重条件や動作条件を考慮するために使用されることもあります。

また、Ampleon社では、より高度な材料モデルやシミュレーションモデルが必要な場合は、Ansysの構造シミュレーションを活用しています。そうしたケースでは、Workbenchのインターフェースを介して統合が行われます。Workbenchプラットフォームを使用することで、機械シミュレーションの結果を電磁界ソルバーに入力し、熱的に誘導された変形が製品のEM性能に与える影響を計算できます。

また、エンジニアたちはIcepakを使用して、パッケージ、基板、およびシステムレベルでの冷却方法を調査して最適化し、RaptorXを使用して、高度なMMIC製品のEM性能を最適化しています。

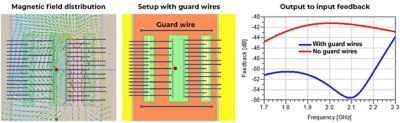

Ampleon社では、Ansys Electronics Desktop™の電磁界シミュレーションを活用して、実装デバイスの入力から出力への結合を低減するための対策を特定している。この結合は、入力においてワイヤを通過し、出力においてワイヤによって発生する磁場が原因であることが多い。考えられる解決策は、トランジスタの側面に保護線を追加して流出場を減らすことである。この特許取得済みのソリューションにより、結合を大幅に削減できる。

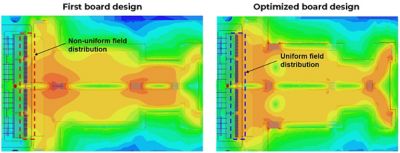

Ampleon社のエンジニアは、Ansys Electronics Desktop™で電磁界シミュレーションを使用して、プリント回路基板の設計を最適化し、一様な電磁界分布を保証している。

ベネフィット

Ampleon社では、Ansysのシミュレーションを導入して、電力消費量に対する電力供給量の比率が適切であることを確認し、製品の運用効率を最適化しています。これにより、ユーザーはより持続可能な未来のためにエネルギーコストを節約できるようになります。

システムレベルのシミュレーションは、高温部分や高い応力レベルに起因する信頼性に関する潜在的な問題を調べて対処するのにも役立ちます。シミュレーションを設計の早期段階で行うことで、コストと時間のかかる再設計を回避できるようになり、コストを削減して、市場投入までの時間を短縮できます。

Ampleon社のシニアプリンシパルエンジニアであるVittorio Cuoco氏は次のように述べています。「Ansysのツールを使用することで、正確な電磁界およびマルチフィジックスシミュレーションを実行できます。チップ、パッケージ、基板、冷却ブロックなど、複数のスケールでさまざまな課題に取り組むためには、Ansysのツールは不可欠です。」

Ampleon社のエンジニアは、Ansysのマルチフィジックスシミュレーションを使用して、システムレベルで温度分布を可視化し、値が安全限界内に収まっていることを確認している。

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。