See how the TAG Heuer Porsche Formula E Team could create an entire operating picture of the season in a single simulation environment.

In the world of motorsport, the ABB FIA Formula E World Championship establishes a significant connection between racing and any future electric vehicle (EV) innovations we can expect to see on the road. The sport has been called an idea incubator for novel ideas like more efficient e-motors and power electronics, as well as fast-charging batteries that will help move us closer to an all-electric future.

There’s a reason for this. During a race, drivers are tasked to push the limits of electrification above and beyond what a passenger vehicle will experience in most driving conditions. All the data collected at the track, plus data accumulated from simulation of various systems and components, the wind tunnel, and the driver simulator, is analyzed independently to understand how to extract every last bit of vehicle performance.

What if racing teams could test all the systems, as well as systems of systems, that define a race in a single virtual environment? Let’s consider how simulation is supporting the TAG Heuer Porsche Formula E Team now and how Ansys digital mission engineering (DME) software could enhance this analysis in the future.

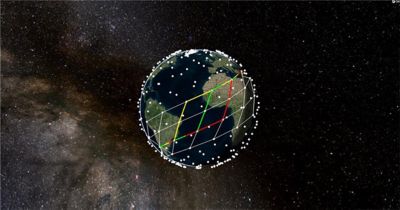

Ansys Systems Tool Kit (STK) software is a physics-based application that helps analyze systems in operational environments.

Defining the Mission in Formula E

Before we talk about DME, it’s important to identify the overall mission of the ABB FIA Formula E World Championship, which is to promote sustainable mobility by flexing on extreme capability. It’s one that Porsche intends to pursue in Formula E, both on and off the track. And what better way to prove this point than to engineer an electrified race car that can drive on the extreme edge of efficiency for 45 minutes at up to 200 miles per hour like the Porsche 99X Electric?

In a sport where efficiency is a competitive advantage, the engineers and drivers of the TAG Heuer Porsche Formula E Team are laser-focused on winning. Their mission is to find that sweet spot during vehicle optimization that keeps the Porsche 99X Electric running on a single charge and delivers the best performance during qualifying and the actual race. Soon, however, Formula E intends to add a pit stop to recharge the batteries called a “Pit Boost.”

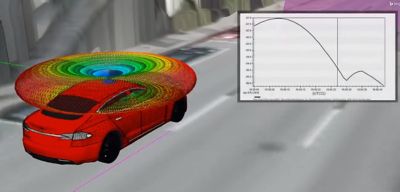

In this case, the main driver for optimizing efficiency in the Porsche 99X Electric’s development workflow is Ansys simulation. Porsche engineers rely on simulation to perform large numbers of runs in a small amount of time and in parallel. Their objective is to analyze the interaction of the numerous components of the Porsche 99X Electric, particularly those of the electrified powertrain, and how to set them up to get the best performance.

Throughout the season, the team runs simulations against different car setups and track conditions to determine different baselines for further analysis. Concurrently, drivers run through multiple car setups and test out different driving strategies under various conditions in a driving simulator to understand how the car feels if something is changed. All the resulting simulation and track data is then transferred via data network from the data center to the track and back again.

During races, however, there are very few possibilities to receive live data from the car, as telemetry, or the automatic measurement and transmission of data, is prohibited by the FIA. In this instance, Porsche engineers are limited to timing-based analysis, or evaluating vehicle performance based on speed, acceleration, or other factors, against the competition.

Pulling It All Together

A consequence of all this activity, of course, is data — and lots of it. The team’s testing and analysis rely on the successful merging of data from many disparate sources. It requires a lot of coordination, as all must be analyzed together to help engineers reach conclusions that bring the TAG Heuer Porsche Formula E Team a few steps closer to the podium. DME software has the potential to pull it all together in one environment that considers vehicle performance in the context of an entirely digitally modeled racing environment.

Dynamic modeling with Ansys digital mission engineering (DME) software

DME is the use of digital modeling, simulation, and analysis to represent systems in a realistic operational environment and evaluate mission outcomes and effectiveness at every phase of the system engineering design life cycle. It currently provides a foundation in aerospace and defense applications on which you can integrate digital mission and system models to develop a true engineering analysis environment that measures mission effectiveness and defines outcomes across all levels of fidelity — from development through operation, maintenance, and sustainment.

The approach to DME using tools like Ansys Systems Tool Kit (STK) software is, in the simplest of terms, a method by which a digital representation of your system (or systems) can be simulated under the conditions in which it is expected to operate, ultimately resulting in quantifiable measures of performance.

Mission effectiveness in the context of Formula E would be specifically measured in the substantiation of extreme, sustainable performance on the track, expressed in terms of both efficiency and speed, with potential to find its way to the street.

“What we’re trying to offer Porsche or any other customer across the board is a way to take all these disparate simulations, put them into one common operating environment, and make sure that they’re seeing all of the right things at the right time,” says Joshua Reicher, manager, product management for DME, Ansys. “And that they’re moving the information back and forth to the right simulation tools as needed. In this way, in this sharing of data, the goal is to create a common operating picture.”

STK software can incorporate radio frequency impacts while exploring vehicle link quality in urban environments.

Big-Picture Thinking That Wins Races

What STK software offers is a common operating picture based on what information Porsche engineers have available to them at any point in time and a means to represent all of it in a single mission environment. From there, they can determine what the electronics are doing or if they have any structural issues with the vehicle.

Maybe they are interested in understanding how temperature differences in Berlin might impact a battery’s state of charge versus temperatures in Jeddah, Saudi Arabia, or similar challenges when navigating a particular course. STK software makes it possible to analyze variables like these in a single viewpoint and be able to see everything in a single environment.

“Every last detail of the racing environment can be modeled inside a realistic and time-dynamic three-dimensional simulation,” says Washington Wedderburn, principal product manager in DME at Ansys. “Assuming you have a decent model of the operating environment, it’s possible to gauge GPS performance in urban areas where tall buildings might impact your ability to get accurate readings.”

The new Porsche 99X Electric GEN3 Evo sets the pace during a preseason test run in Madrid.

Modeling Systems, as Well as Systems of Systems, in a Single Simulation Environment

Up to this point, we’ve talked about all the data that the team relies on and how it all comes together with the help of simulation to inform overall racing strategy. What if it was possible to model all vehicle systems, as well as systems of systems, inside a single realistic, time-dynamic 3D simulation in high-resolution terrain, imagery, and radio frequency environments in action from any location at any time, including weather and track conditions?

These new capabilities would give the TAG Heuer Porsche Formula E Team the opportunity to thoroughly evaluate and validate its assumptions against an unlimited number of test cases on city-centered street courses, from Shanghai to London, in a single virtual environment. The team could then apply all this new data to formulating strategy in anticipation of all the on-track interactions that might ensue during a race.

Making Important Connections Between Worlds

To really understand vehicle performance, it’s also possible to introduce a digital model, such as a digital twin of the race car itself, into STK software in this operating environment. A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.

Creating a digital twin of the Porsche 99X Electric, then introducing it into the system environment with a bridge to the physical car, means there’s something in the digital world representing a physical system. At the same time, it enables the use of real-world data to drive the digital model. Real-time data integration from various vehicle sensors and systems on the actual race car into the digital twin helps engineers more accurately observe how aspects of the Porsche 99X Electric impact efficiency in a variety of conditions in a simulation environment.

Did You Know?

One of the common concerns for drivers that is emphasized in motorsport is stress to the driver’s neck due to all the g-forces involved during a race, especially when cornering. Syncing Ansys LS-DYNA nonlinear dynamics structural simulation software with STK software presents an opportunity to introduce a human body model of a driver, as well as models of all the structural elements protecting the driver, into a single virtual testing environment. These include the helmet, the head and neck support (HANS) device, safety belts, and the safety cage surrounding a driver. It’s a great example of how Ansys software can improve driver safety on the track.

“Incorporating a digital twin similar to the structural model that’s going to be fed from the mission simulation back and forth from the simulation to the actual race car, it’s possible to get valuable information on position and velocity over the course of a race in STK that can be plotted in STK,” says Reicher. “From there, it’s possible to derive information that can feed multiple digital twin models — potentially electronic models of the battery or aspects of the vehicle that can be used for predictive maintenance, such as tire wear and tear or battery state of charge.”

This discussion has only touched on the tremendous potential for Ansys software to extend the entire operating environment of one motorsport team in a virtual world. You can find more on our digital mission engineering page.

Just for you. We have some additional resources you may enjoy.

“What we’re trying to offer Porsche or any other customer across the board is a way to take all these disparate simulations, put them into one common operating environment, and make sure that they’re seeing all of the right things at the right time.”

— Joshua Reicher, manager, product management for DME, Ansys