-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

Ansysブログ

March 26, 2024

STMicroelectronics社がシミュレーションを利用して、SiCモジュールの設計を実現

STMicroelectronics社が、新しいエネルギーおよび産業ソリューションを推進するための電気自動車向け製品の開発において、Ansysのシミュレーションをどのように活用しているかをご覧ください。

パワーエレクトロニクスは、日常生活で使用する個人用デバイスから電気自動車(EV)、さらにこれらすべてを支えるデータセンターに至るまで、急速なイノベーションを背景に目覚ましい発展を遂げています。ある製品が市場に登場したかと思えば、すぐにその次世代モデルが現れ、私たちの期待を上回る性能を実現しています。

パワーエレクトロニクス(「ハイパワーエレクトロニクス」とも呼ばれる)は、高電圧と高電流の管理を伴うため、一般的なデバイスとは異なります。中でも、最も代表的なものが半導体です。マイクロチップ内では、高性能パワートランジスタが大電流を効率的に伝導して、ハイパフォーマンスコンピューティングをはじめとする、さまざまな用途に対応しています。これらはすべて、わずか数ミリメートルのチップ内で行われています。

パワーエレクトロニクス業界で注目されている半導体の1つが炭化ケイ素(SiC)です。導電率が高く、熱膨張が低いという特性から、高温になる環境に適しており、半導体とシリコンの代替材料となっています。こうした理由から、SiCは次のようなさまざまな電力用途に適しています。

- EV充電システム(インバータ)

- エネルギー処理(生成、変換、分配貯蔵)

- 産業機械(製造工場におけるマスマーケット向けロボティクス)

- データセンターの電源

炭化ケイ素ウェハ

現在、EVおよびパワーエレクトロニクス市場の急速な需要拡大により、SiCベースのコンポーネントやシステムに対する需要が高まっています。2030年までのEVの販売台数は、2022年の推定販売台数の4倍にあたる6,400万台に達すると予測されていますが、これを実現するためには、SiCコンポーネントの安定した供給が必要になります。さらに、最近の研究では、SiC金属酸化膜半導体電界効果トランジスタ(MOSFET)は、高いスイッチング周波数、熱抵抗、および破壊電圧のためにEVパワートレインの進歩に不可欠であることが示されています。

半導体業界を牽引するSTMicroelectronics社にとって、これは朗報です。同社は、初の自動車グレードSiC MOSFETを開発し、現在では、STPOWER™ SiCデバイスが、世界中で500万台以上の乗用車に搭載されています。同社では、最終的なEVシステムの性能、ロバスト性、信頼性に影響を与えるあらゆる側面を評価するために、Ansysのシミュレーションを活用しています。Ansysのシミュレーションを活用することで、電力および持続可能なエネルギー産業分野における効率、性能、信頼性の向上が実現し、STMicroelectronics社の第3世代SiC MOSFETの他の市場での成功にもつながっています。

STMicroelectronics社の研究開発部門、CADおよびモデリング担当マネージャーであるGaetano Bazzano氏は、次のように述べています。「Ansysのシミュレーションを導入することで、自動車分野の枠を超えて事業を拡張できるようになりました。SiCモジュールテクノロジーは、ソーラーインバータやエネルギー貯蔵などの持続可能なエネルギーソリューションに必要なパワーエレクトロニクスを提供するために不可欠です。また、モータ駆動、電源、ロボティクスを伴う電力制御の分野にとっても同様に重要です。」

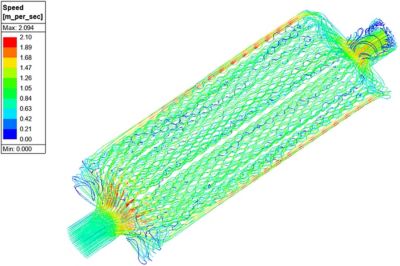

流体速度の流線

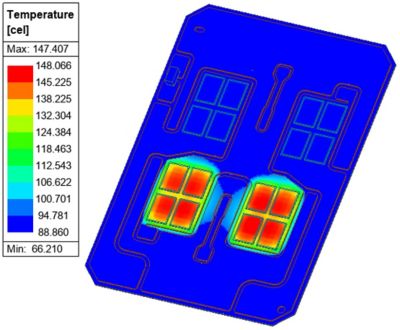

熱のシミュレーション

コンポーネントとシステムのパワーエレクトロニクスの性能は、設計と製造に用いられる材料、つまり導体、半導体、絶縁体の電気伝導特性によって左右されます。この3つの中でも半導体の導電率は特に重要であり、エネルギー効率、シグナルインテグリティ、熱マネジメント、信頼性の面で特定の用途に合わせて操作できるため、これらのコンポーネントの開発において鍵となります。

今日、パワー半導体SiCは、信頼性が最も重要となるEVをはじめとした、さまざまなエレクトロニクス分野においてますます重要性が高まっています。なぜなら、そうした分野の製品の多くが極端な高温に耐える必要があるためです。材料の組成に応じて温度が変動すると、各システムに搭載された電子部品は、さまざまな熱膨張の影響を受けます。この熱膨張の違い、すなわちコンポーネント間の形状の変化は、熱応力を引き起こし、機械的な故障につながる可能性があります。

STMicroelectronics社は、Ansys Icepakで熱-機械シミュレーションを実行することで、こうした環境条件に影響されるSiCパワーモジュール設計の挙動と健全性を迅速かつ正確に評価し、早期故障の可能性を特定することができます。エンジニアは、仮想環境でデバイス内の熱分布を評価して、システムに負荷を与え、過熱や故障につながる重要なポイントを特定して対処できるようになります。

電源モジュールの熱分布マップ、シングルスイッチ温度挙動

効果的な冷却メカニズムの考慮

電力損失を最小限に抑えることは重要ですが、大電流によって発生する熱は、特に高温環境でパワー半導体モジュールの故障を引き起こします。したがって、モジュールの性能、信頼性、効率、寿命を損なうことなく、連続出力を達成するための高い電力密度を維持するためには、効率的な冷却メカニズムを検討しなければなりません。

冷却技術を導入することで、熱伝達率(半導体デバイスから熱が放出される速度)が向上します。しかし、冷却技術を導入すると、システム内の圧力損失が大きくなったり、冷却材の流れに対する抵抗レベルが高くなったりすることがあります。この抵抗の増加により、コンポーネントを冷却するための冷却液(このケースでは空気または液体)をシステム内に流し込むために、より多くのエネルギーが消費されます。さらに、圧力損失は熱伝達率を低下させ、システム効率に影響を与えることもあります。

そのため、自動車向けのさまざまなコンポーネントで最適な熱性能を達成するためには、熱伝達率と圧力損失レベルの間で最適な妥協点を見つけ出すことが不可欠です。

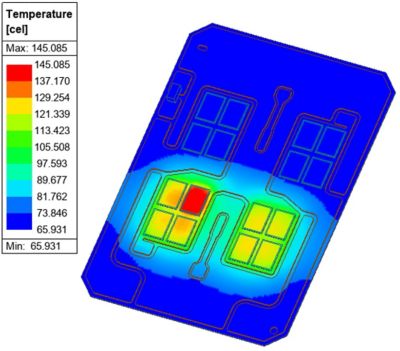

同じスイッチに属するバランスの取れていないダイを考慮したパワーモジュールの熱マップ

Ansys Mechanicalを活用してすべてを統合

STMicroelectronics社では、構造シミュレーションを活用してモデルモジュール全体の構造健全性を評価しています。構造シミュレーションでは、動作中に発生する振動、衝撃、変形などの応力が考慮されます。エンジニアは、Ansys Mechanicalで特定のモジュール設計を解析することで、最高の動作性能を得られるようにそのモジュール設計を最適化して、故障のリスクを減らし、デバイス全体の信頼性を向上させることができます。

Ansys Mechanicalで機械および熱-機械シミュレーションを実行すると、実際の動作条件下でのパワーモジュールの挙動に関する重要な知見を得られ、適切な熱放散と信頼性が確保されます。このような詳細な解析により、パワーモジュールの重要なポイントを特定し、設計を最適化してロバスト性を向上させながら、コストがかかる物理プロトタイプの数を最小限に抑えることができます。

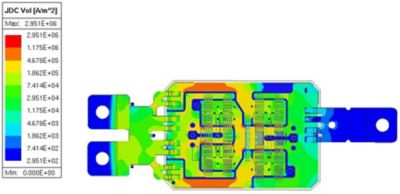

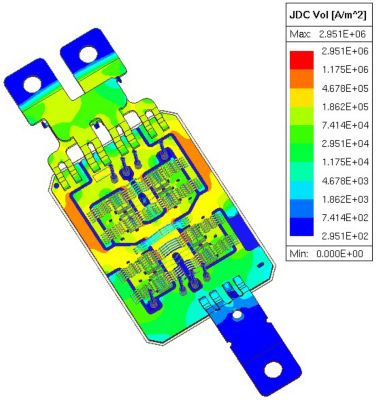

dc+からdc-への電流密度マップ

すべての物理現象は、相互に依存しています。ナノメートルスケールのトランジスタデバイスから、インバータなどのミリメートルおよびセンチメートルスケールのSiCモジュールまで、さまざまなレベルで相互作用する熱、流体、構造の影響を同時に解析しなければなりません。Ansysが提供する真のマルチフィジックスおよびマルチスケールシミュレーションソリューションは、高度なSiCモジュールの仮想検証に適した環境を提供します。

Bazzano氏は次のように述べています。「パワーモジュールの解析においても、構造シミュレーションや熱-機械シミュレーションの有効性は同様に重要です。私たちは、信頼できるソルバーであるAnsys Mechanicalを使用して解析を実行しています。Mechanicalは、SiC MOSFET設計の構造健全性を理解するために非常に重要な役割を果たしています。このツールのおかげで、潜在的な問題を早期に特定し、プロトタイプ作製と開発作業を大幅に削減できました。改善点を早期に特定できることで、結果的に、ユーザーの開発時間と開発コストの効率化も実現しています。」

インバータ、コンバータ、センサー、半導体など、Ansysがパワーエレクトロニクスシステムのシステムレベルの設計および最適化ソリューションを実現している様子をご覧ください。