-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

November 28, 2023

Getting to Know Design Optimization

Artificial intelligence (AI) and machine learning (ML) methods are being applied to design and development in a wide range of industries from aerospace and automotive to consumer electronics and healthcare. When used in tandem with simulation, computer-aided engineering (CAE), and other computer-aided design (CAD) tools, AI/ML can significantly enhance design exploration and optimization, benefiting a broad spectrum of applications.

Ansys’ optimization solutions offer built-in capabilities that leverage these AI/ML methods. Ansys optiSLang is a process integration and design optimization software solution. Its state-of-the-art algorithms, including AI/ML, automatically search for the most robust design configuration, eliminating a slow, manual process. Additionally, its AI/ML algorithms help guide simulations, which increases efficiency, minimizes manual input, and ensures that you’re selecting the best optimization techniques for your needs. Let’s explore how optiSLang leverages AI/ML for optimization.

What is Metamodeling?

In simple terms, a metamodel is a model of a model. Metamodeling is just the process of generating such models. OptiSLang builds metamodels for rapid feedback and robust design analysis in a fraction of the time it would take to run a simulation to predict a certain design.

Often engineers need to review hundreds to thousands of values when preparing a model. But what if desired values are not available from previous studies, tables, or research? Historically, engineers use interpolation — estimating values between two given data points — to find missing data but this is not an ideal resolution by itself. Yet conducting additional laboratory tests to help estimate values is costly and unrealistic in many cases. Alternatively, simulation can be used to replace expensive hardware tests and evaluate phenomena that cannot be measured otherwise.

Still, running thousands of simulations to find an optimal point or value can be burdensome and time consuming. Conversely, AI/ML techniques interpolate with neural networks that contain many dimensions and variables. With this insight, you can create a lookup table for the interpolation scheme and run simulations using focused data to get the results you really need. Ultimately, metamodeling empowers teams to run simulations faster, explore broader design possibilities, and reduce development costs.

How optiSLang Leverages AI/ML

As mentioned, engineers typically run a large quantity of simulations to conduct parametric studies like optimization. Conducting these manually would not only be time consuming, costly, and unrealistic, but it would also be unguided, resulting in blind, broad searches. This is where AI/ML really helps.

AI/ML algorithms guide simulation and eliminate random searches or modeling that produces unneeded results. This increases efficiency and enables you to understand the design more deeply, including parameter influences, coherences, and output selection. It also helps you choose the best metamodeling approach.

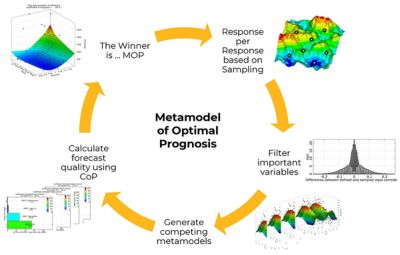

Ansys optiSLang’s metamodel of optimal prognosis (MOP) algorithm finds the best metamodeling approach and prepares its settings.

Finding an appropriate metamodel can take a lot of time and its number of parameters influences the data needed to train the AI/ML algorithm. To remedy this, Ansys offers the metamodel of optimal prognosis (MOP) approach. MOP is an automatic ML (AutoML) algorithm in optiSLang that finds the best metamodeling approach and prepares its settings. It also filters important parameters and works for 0D scalar-values. OptiSLang also includes the signal metamodel of optimal prognosis (signal MOP) algorithm — which is designed for curves — and the field metamodel of optimal prognosis (field MOP) algorithm — which is best for 2D or 3D models.

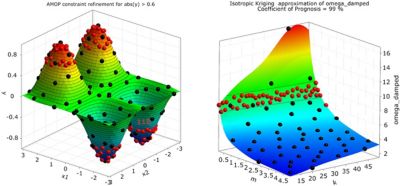

Another one of optiSLang’s AutoML algorithms is the adaptive metamodel of optimal prognosis (AMOP). As its name suggests, AMOP is adaptive. This means that after the initial DOE, AMOP automatically creates MOP for the outputs. It finds regions where the metamodeling is favorable and regions where new observations could improve quality. Based on this insight, AMOP automatically runs new simulations for future iterations. In this way, AMOP redefines the DOE where needed to achieve the best metamodel quality, requiring less manual input and simulations.

For this reason, engineers do not need extensive AI/ML knowledge to use MOP or AMOP and anyone can benefit from its automated parametrization. Similarly, they can automate parametric DOE to generate training data with minimal effort by combining simulation and parametric algorithms in any of Ansys’ flagship simulation solutions or within the optiSLang GUI.

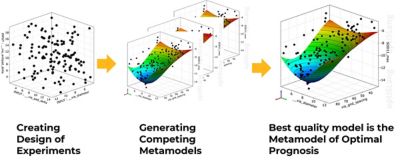

Generate Design of Experiments More Easily

OptiSLang has several methods for DOE. Classical deterministic DOE, such as a grid, is suitable for a few parameters. However, if there are several parameters like thickness, speed, roughness, etc., then better suited algorithms and advanced techniques are used like Latin hypercube sampling (LHS).

Training MOP is also fairly easy because MOP, signal MOP, field MOP, and AMOP are data agnostic. Data from your DOE, simulations, other files, and related results is automatically extracted and forwarded to MOP, fed into the MOP algorithm, and ran automatically. Additionally, MOP surveys different approaches in a “competition of metamodels” in which coefficient of prognosis (CoP) values are measured and compared using cross-validation. MOP selects the best metamodel and provides its parameters and their influence.

OptiSLang’s metamodel of optimal prognosis (MOP) algorithm performs a “competition of metamodels” in which coefficient of prognosis (CoP) values are measured and compared using cross-validation.

Still, engineering tasks often have 20 or more parameters for geometry, load, process, and more, requiring engineers to test multiple parameters before finding the best fit. MOP’s sensitivity analysis lessens this load by identifying which parameters have the most influence on an output. This minimizes manual effort and concentrates the search only on relevant parameters. This also assists in the building of metamodels. For example, a metamodel with 10 parameters may require you to search thousands of datapoints to reach a desired resolution. However, with simulation-powered metamodeling and optimization, you can focus only on the needed parameters and achieve higher resolution using less data points.

AMOP concentrates value searches on the most relevant parameters, accelerating simulation time and increasing efficiency.

Optimization in a Click

There are several optimization algorithms, each good for specific tasks. Essentially, optimization algorithms search for optimal settings. In general, all optimizers “play” with the parameters of a model while staying in the parameter range that was given. Play means they iterate over various sets of parameters and drive simulations.

Metamodel-based optimizers help to achieve an optimal set of parameters using less simulations by using response surface modeling (RSM) for surrogate models or metamodels. Choosing an appropriate metamodel with the right setting can be difficult. While MOP and AMOP already alleviate this burden, Ansys’ one click optimizer (OCO) takes it a step further. OCO is a newer algorithm within optiSLang that uses MOP philosophy to not only select the best metamodel but also the best optimization approach. Similar to MOP’s competition of metamodels, OCO places optimization approaches against each other to determine the most ideal with just a simple click.

AI/ML Innovations on the Rise at Ansys

Ansys is constantly developing new AI/ML innovations to enhance simulation, optimization, and related workflows.

The Ansys AI+ technologies will be available on a rolling basis beginning this fall, starting with the release of Ansys optiSLang AI+, which will expand upon the AI/ML-based metamodel capabilities discussed in this blog. Ansys Granta MI AI+ will follow soon after and feature ML modules.

For more information, review the latest announcement and stay up to date on the latest AI/ML advances at Ansys. To discover optiSLang firsthand, request a free trial.