-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

September 27, 2022

Ansys-Microsoft Solution Enables Electromagnetic Analysis of Entire Chip Designs

As wireless connectivity continues to accelerate, so does the demand for smaller, faster, more power-efficient high-performance electronics including cell phones, computers, and complex radar systems. Consequently, device sizes are shrinking as performance expectations grow to match consumer expectations. Radio frequency integrated circuits (RFICs) are key enablers of the wireless transceiver’s shift to a single technology and ultimately, a system on a chip solution. Specifically, RFICs facilitate the integration of most electronics components into a single chip that supports smaller, more power-efficient designs.

In this environment, manufacturers are struggling to keep up. That’s because RFICs operate at high frequencies, so they require precise noise isolation between digital and analog blocks. Chip analysis can be challenging for electronics manufacturers without a sound testing strategy. Ansys, in recent partnership with Microsoft, changed this narrative by accurately and successfully simulating the electrical properties of full RFIC designs to help engineers meet the strict performance requirements that go into these more complex chip designs.

In a recent interview, Andy Chan, director of Azure Global Solutions Semiconductor/EDA/CAE at Microsoft says, “With this new tool available to RF designers, it will help them to keep pace with the innovation that the market demands.”

Just how significant is this development? Previously, due to computational complexity and meshing limitations, engineers had only two simulation options — either simulate a full IC using a tool with a medium level of accuracy or simulate a partial IC with higher accuracy. Depending on the approach, they could only validate electromagnetic activity either early or late in the design process, in either lower- or higher-frequency applications respectively.

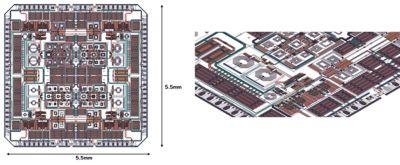

Figure 1: Top and angled view of an integrated circuit in Ansys HFSS

Ansys HFSS + Ansys Cloud Direct on Microsoft Azure = Full RFIC Analysis

Using Ansys HFSS layout automated IC-specific meshing in Ansys Cloud Direct on Microsoft Azure enabled engineers to completely solve an adaptively converged mesh (15 passes) for an entire RFIC (5.5 x 5.5 mm) at 5 GHz in under 30 hours. The model has 64 ports distributed across the entire IC. This was accomplished utilizing 704 compute cores (Intel® Xeon® Platinum 8168, Azure “HC44” VM), with an initial mesh solve time of one hour and 55 minutes with a final mesh size of 23.5 M Tetrahedron and 93 M unknowns. Additionally, the final mesh point solution time (5 GHz frequency point solved after adaptive pass 15) was two hours and 19 minutes, and total adaptive mesh time was 29 hours and 47 minutes.

The team leveraged the supercomputing power of the HC44 VM featuring 100 Gb/sec EDR InfiniBand, and Azure’s unique InfiniBand fabrics of H-series VMs to host the workload in HFSS. Azure InfiniBand fabrics technology is based on non-blocking fat trees with a low-diameter design for consistent low latencies. Together, with SR-IOV (Single-Root I/O Virtualization), it enables Ansys to use standard Mellanox OFED drivers just like they would on a bare metal HPC cluster.

To successfully analyze the entire chip, advanced meshing and geometry preparation capability in HFSS was first required, enabling adaptive mesh algorithms in the software to efficiently handle the layered 3D chip structures in the IC — resulting in a final mesh that accurately captured the relevant physics. From there, the problem was solved on the cloud, enabling the team to harness all required RAM across 16 HC compute nodes. Ansys Cloud Direct R&D teams also partnered with Microsoft Azure engineers to ensure customers had a robust and user-friendly way to access all this compute power.

Figure 2: Ansys HFSS simulation of RFIC employing Mesh Fusion at chip, package and PCB levels

A Big Boost for Chip Development

Using Ansys Cloud Direct’s simple GUI, companies of all sizes gain access to supercomputing-like capability on-demand, regardless of the machines and region they choose — with a performance boost from Intel® Xeon® Platinum 8168 CPU’s with AVX512 on Azure HC-series machines. In this environment, users benefit from on-demand access for most Ansys solvers, including: HFSS, Ansys Maxwell, Ansys SIwave, Ansys Mechanical, Ansys Fluent, Ansys LS-DYNA, Ansys Discovery, and more.

Again, the big news here is that advancements in HFSS meshing, coupled with cloud computing via Azure make it possible to analyze the full-wave electromagnetic activity and extract coupled models for an entire RFIC. For manufacturers, this could mean avoiding big mistakes, problems, or product delays that could literally cost them millions. Now, this solution enables engineers to simulate a full RFIC using the highest-level accuracy tool possible.

If you would like to hear more about how this Ansys-Microsoft full-IC simulation solution is helping companies assess entire chip designs faster, be sure to watch the full interview with Andy Chan, director of Azure Global Solutions Semiconductor/EDA/CAE at Microsoft and Jonathan Austin, Global Black Belt for Semiconductor at Microsoft.