-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Simulation-Driven Design Makes Waves

By Ansys Advantage Staff

Munich, Germany, may be best known as the world’s beer capital, but the landlocked city is also famous for another form of liquid refreshment: river surfing. The wet and often wild sport was invented in the Floßlände channel in Munich in the 1970s, and grew in popularity when a wave formed, somewhat by accident, on the Eisbach River as it flowed through the English Garden.

To calm the rushing river’s current as it flowed through that tranquil park in central Munich, engineers placed concrete blocks into the water. The blocks had the unintended consequence of creating a fast, shallow, surfable wave. Surf fans began amplifying the wave’s force by tethering planks along the sides to narrow the channel. The result was Eisbachwelle, now Germany’s premier river surf destination.

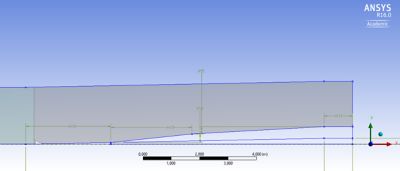

The geometry of the channel and wave generation device is fully parameterized. Structured meshes and computational fluid dynamics setups are automatically generated

Unlike surfing on dynamic coastal waves, river surfing is done on standing waves, tidal bores or upstream waves. And while that might give the impression that river surfing is a tame facsimile of the ocean experience, the fact is that Eisbachwelle can be a bumpy ride, suitable for seasoned surfers only. Beginners can fine-tune their skills on the stationary wave at Floßlände, which is smoother and safer than the Eisbachwelle. Taking the entire concept of stationary waves into a new dimension is Surf Langenfeld, where surfers of all levels can catch waves on the world’s first standing deep-water wave on a lake. It was built by UNIT Parktech A.G., in 2017.

Dr. Robert Meier-Staude, a professor of mechanical and process engineering at the University of Munich, and his team used Ansys Workbench and Ansys CFX to revitalize Floßlände in 2014. In 2017, they enlisted the same simulation software to produce the world’s most powerful artificial wave at Surf Langenfeld in the Rhineland. Both were completely simulation-driven designs that resulted in the production of polyurethane lamella devices — a solution that has worked well under considerably different conditions at both Floßlände and Surf Langenfeld.

AN OLD WAVE BECOMES CURRENT AGAIN

The gentler of Munich’s stationary river waves, Floßlände was a popular tourist destination for new and less experienced surfers for more than 40 years — until 2014, when local authorities reduced the amount of water flowing into it and nearby construction projects made conditions even worse. At that point, the wave became unsurfable.

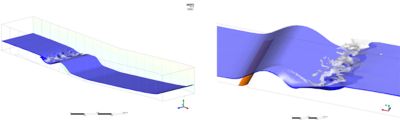

The left side of the leftmost 3D transient calculation of the wave shows the symmetry plane with contour lines of the “yImpuls.” The right marks the channel wall. From the calculation, we should expect a perfect “green face” of the wave. The rightmost detail view (flow from left to right) from the wall side of the channel assists in studying how the sidewall affects the wave.

River surfers themselves, the team led by Meier-Staude was determined to figure out what contributed to the sensitivity of flow conditions and then to develop a device that would produce a surfable wave using less water. To further complicate the project, whatever they designed could not be an obstacle for other channel traffic, including swimmers, kayakers and timber rafts carrying tourists. The solution relied on a fully parameterized virtual prototype without real-world testing or physical prototyping.

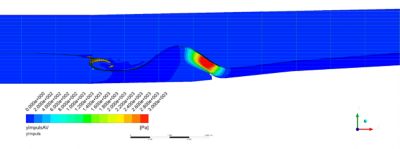

The first step was establishing the criteria for a “good wave,” which included defining the control and pressure inputs. Because the greater the pressure, the more exciting the ride would be, the team concluded that for the wave to be surfable, vertical pressure had to be at least 3,000 pascals (Pa), which compares to a 3-foot ocean wave traveling at a speed of 5 meters per second.

To design this powerful wave using a minimum amount of water, Meier-Staude and his team turned to Ansys CFD. By enabling qualitative and quantitative parameter studies, Ansys CFD was key to understanding the mechanisms that would form the wave and to calculating the fluid forces on the wave-forming device, an apparatus that had to be strong enough to withstand the waves but pliable enough to not endanger other channel users.

To start, the team produced 2D simulations of flow conditions based on various amounts of water moving into the channel. By testing various upstream and downstream water heights, they determined the optimal difference needed between the two to create enough energy to produce the wave.

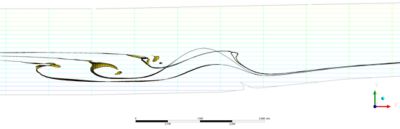

Parameter studies of the wave surface as a function of the downstream height of the water; the wave the surfer loves most is the wave just before it breaks.

Ansys software provided both the fine mesh resolution and the crucial boundary layer resolution required to simulate the wave. 3D calculations offered insight into the effect of sidewalls. Because the results were nearly the same whether they used steady-state or transient simulations, the team finalized the virtual prototype with steady-state simulations, which reduced calculation time and compute power requirements.

In 2015, the city of Munich agreed to test the team’s wave generation device, installing a series of 27 thin sheets of polypropylene (PP) — referred to as lamellas — on a succession of curved wood pieces. The lamellas have sufficient elasticity that the wave remains stable for surfers but channel traffic can push them to the ground and out of the way.

Vertical dynamic pressure of the flow “yImpuls” for an optimized device: Maximum wave height and wave power are achieved with a minimum amount of water and minimal device height. The red area meets the design criteria (the sweet spot for the surfer) with an yImpuls of yImpuls > 3,000 Pa. This area should be surfable for surfers weighing 80 kg (176 pounds) or more.

The reinvigorated wave at Floßlände can be surfed with a 5-foot, 3-inch shortboard. It has been working exactly as designed for more than five years.

THE WORLD’S MOST POWERFUL MAN-MADE WAVE

Thanks to the success at Floßlände, in 2016 UNIT Parktech, a German company specializing in the construction and design of wakepark features, asked Meier-Staude to develop a surfable wave in a lake at a water-skiing facility. The first-of-its-kind request was unusual enough, but on top of that, the company wanted Langenfeld to have the most powerful stationary wave anywhere.

To achieve the ambitious goal, Meier-Staude and master’s candidate Jakob Bergmeier once again turned to simulation-driven design. Leveraging the lessons from Floßlände, they developed a prototype surf pool from fully parameterized geometries. Considerations were similar to the earlier project, including flow angles, water volume and water height, both upstream and downstream. But this time, they also had to model a vertical lift system — a pump delivering as much as 10,000 pascals of force — that would generate and preserve the integrity of a wave over a steep ridge in an area 20 m wide and 50 m long. In addition, the surf pool had to be energy-efficient.

Bergmeier and Meier-Staude began by designing 2D and 3D flow, then used Ansys CFD to simulate operation, optimization, and starting and stopping the wave. The design incorporated the same kind of energy-efficient pumps used in water treatment plants. The pumps raise the lake water about 1.2 meters above surface level in the contained area of the surf pool; gravity drives the water quickly over an HDPE lamella covering a ramp, and the hydraulic jump phenomenon generates a deep-water wave in standing water — a 4-foot wave for beginners and a 5-foot, 3-inch wave for advanced surfers.

Hannes Herrmann, the first surfer on the New-Thalkirchen wave on July 1, 2015 (photo credit: Philipp Altenhöfer)

CONCEPT TO COMPLETION IN MONTHS

Simulation for the design of the Langenfeld surf pool took about four months; building it took just a few more. In less than a year, the most powerful artificial wave in a lake was ready for surfing. Since then, UNIT Parktech has fine-tuned their technology and installed an even larger surf pool in Milan, Italy.

Compared to the traditional iterative method of beginning with a model, simulating it and then going back to refine the model, using Ansys software for simulation-led design considerably shortened the time from concept to completion. But more than that, without virtual prototyping, neither project would have been possible.

In essence, simulation really made waves, overcoming water flow conditions and enabling surfing where it was never before possible.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。