-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Simulate, Compete, Repeat

By Eric Warren, Chief Technology Officer and Eric Kominek, Chief Designer Richard Childress Racing

From basic aerodynamics to critical decision-making tools, simulation has come a long way with NASCAR teams over the past decade. Before that, teams depended mostly on the experience and hunches of the team leader to determine what adjustments to make. Now, at Richard Childress Racing (RCR), it’s rare for a change to be made to a car without management first asking: “What does the simulation show?”

Data-Driven Decisions

The modern NASCAR vehicle is one of the most complex engineering systems on wheels. It’s not a “set it and forget it” system, either. NASCAR race cars require significant modifications on a weekly basis. Each Monday during the normal 36-race season (2020 includes some midweek races to make up for weekends lost to the COVID-19 pandemic and shutdown), engineers compile and analyze the results of the previous race, along with driver feedback and tons of race-day data collected from sensors on the car. They then begin tuning the car for the upcoming challenge the following Sunday.

Each racetrack is different — ranging from 2.5-mile super speedways at Daytona and Talladega to half-mile short tracks — with bank angles from 5 to 33 degrees. Track surfaces and weather conditions change weekly. There are more than 15 different tire construction and compound combinations on each side of the car that vary each week from track to track. Teams are tasked with choosing the proper tire camber, steering alignment and operating tire pressures for the predicted racing conditions.

RCR engineers respond to new rules and prepare for race day using Ansys simulation software.

The engineering team must combine all these factors to determine the best setup for their car for that week’s track, all before Sunday. They get some feedback from drivers after practice runs on Friday and qualifying runs on Saturday, but increasingly they depend on simulations to get their car in optimal shape for the race. This is especially true for the races run after the COVID-19 shutdown, where the teams are required to “show up and race” with no practice or qualifying runs and therefore no time on the track to check to make sure the car is handling correctly.

Engineers at RCR adopted Ansys Fluent computational fluid dynamics (CFD) software and Ansys Mechanical about five years ago to make their Chevrolet Camaro race cars more aerodynamic. In today’s world of professional racing, that requires the ability to create aerodynamic shapes and lightweight structural components, design flexibility into those shapes and structures so they deform under loads and temperatures, and optimize overall lap-time performance while maintaining the high strength needed. More recently, RCR engineers have added Ansys’ adjoint solver, which enables multi-objective shape optimization and topology optimization. RCR engineers are also using high-performance computing (HPC) to handle the high-resolution simulations (with mesh counts reaching 500 million per car) they run each week.

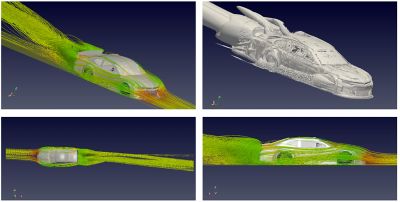

RCR uses Ansys Fluent to understand the complex airflow underneath the race car.

Meeting The Demanda Of Rules Changes

As if the variables involved in racing cars 200 mph on different tracks each week were not enough, NASCAR officials issue a rule package every year that details the design parameters each racing team must meet to be eligible to race. In October 2018, a dramatically different rules package for the 2019 NASCAR Cup Series season was released, instructing the teams to reduce engine horsepower from 750 hp to 550 hp for all tracks over 1 mile in length. The dimensions of the spoiler at the rear of the car were increased from 2.75 inches tall to 8 inches by 61 inches to add drag. The new rules also called for the addition of a tapered spacer in front to reduce air flow to the engine, thereby controlling its combustion efficiency and setting its maximum power.

Why would a racing organization want to slow cars down? Two main reasons emerged. First, speeds were getting dangerously fast along the straightaways, resulting in cars weighing almost 3,500 pounds entering the corners at 218 mph. The momentum, equal to the mass times the velocity, was placing extreme stress on the braking and suspension systems, leading to potentially dangerous situations. Second, it seemed that the results of races were more in the hands of the engineers than the drivers. The team with the most money could fine-tune the downforce on the car to go faster. As NASCAR Executive Vice President and Chief Racing Development Officer Steve O’Donnell explained on NASCAR.com in October 2018: “For us, it’s really a focus on getting back to a true focus on the drivers and what NASCAR is all about — close side-by-side racing and trying to deliver more of that.”

Balancing Drag And DownForce

The new rules greatly increased the importance of drag in the aerodynamic equation for stock car racing. Prior to 2019 at most NASCAR tracks, the primary consideration from an aerodynamics point of view was how much downforce you could produce, because air pushing the car down onto the track harder results in more lateral grip produced by the tires, which makes the car go faster. Drag was only a major factor at the Daytona and Talladega super speedways, where the long straightaways and high banking made low drag a key to reaching top speeds.

In 2019, racing teams now had to look at trade-offs between drag and downforce. A decade ago, that would have involved transporting the car to a wind tunnel and spending $3,500 per hour just to rent the wind tunnel, independent of the costs of test parts and personnel required to run the tests. Typical wind tunnel tests measure downforce and drag, but CFD simulations yield more data while also enabling engineers to envision the whole flow field, all at a much lower cost.

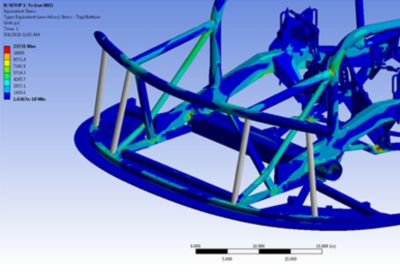

RCR engineers took aerodynamic pressure into account when simulating a new splitter bar in Ansys Mechanical.

Naturally, engineers initially focused their simulations on improving their own cars to comply with the rules, but it soon became apparent that this was not enough. Race cars in tight packs affect each other’s drag and downforce, so they started using CFD to study two-car aerodynamic interactions.

RCR engineers began using Ansys Fluent to run high-resolution simulations of their car positioned in many different locations around another car to create an aero map. The map revealed which relative positions gave them an advantage or put them at an aerodynamic disadvantage in relation to another car. RCR drivers then used this information to position themselves advantageously when driving in a tight bunch of cars. With a knowledge of the CFD results, a driver knows where he needs to be to “side draft” and slow another car down just by positioning his car correctly.

Multiple- and single-car interactions are simulated to prepare for different race scenarios.

Running Race Week MultiPhysics Simulations

RCR engineers normally start configuring a car for a race about three or four weeks beforehand. Drivers practice their skills on simulators to get a feel for how the car will perform ahead of time on a high-resolution model of a given racetrack, accurate to 2 cm. As soon as the car is unloaded at the track, everyone is instantly trying to determine how close the simulations are to reality and deciding how they need to react to any discrepancies. They might make changes to the tire pressure, camber, springs, brakes or other components.

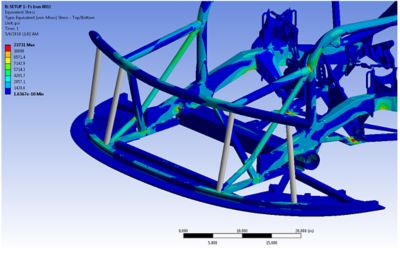

Depending on the track, higher downforce on the front or rear of the vehicle might improve its performance, especially in the turns. RCR engineers use multiphysics simulations, based on Fluent and Ansys Mechanical, to adjust the overall balance of the car. For instance, by simulating the aerodynamic and mechanical loads on the chassis and making physical changes to the car based on them, they can cause the chassis and the front part of the car to bend as much as several inches as it goes into a corner to keep the front of the car down. Similar changes could be made to the rear of the car if conditions called for it.

For these simulations, RCR engineers export the surface plot of the pressure on the splitter (effectively a flat underwing in the front of the car below the radiator) or the spoiler in back from the CFD simulations and import them into Mechanical for structural analysis of these surfaces and the body supports. It’s critical to keep the splitter close to the track while preventing contact with the ground, because contact stalls the air in front of the car. So, they map the pressure onto the surface of the splitter in Mechanical and then use finite element analysis (FEA) simulations to make sure it is stiff enough to handle that pressure while allowing the suspension loads to move in the right direction. Similarly, they perform CFD simulations to get the pressure loads on the rear of the car and then run FEA simulations to ensure that the rear body mounting stiffness is optimized to handle the downforce.

Simulations continue throughout the race weekend. When they were performed using onsite computer clusters, engineers had access to 100 processors and required a lot of equipment and IT staff to run a single CFD simulation in three to four days. Ansys HPC in the cloud has given the engineers more scalability: If RCR engineers need to solve a problem in hours instead of days, they can use HPC to easily scale up to 50,000 cores and finish the simulation quickly.

By using advanced adjoint solution techniques, Ansys Fluent can both identify sensitive geometry changes and actually morph the surface into an optimized shape.

Real-Time Data Analytics

During the race, every team receives data five times per second (5 Hz) including the GPS line and lateral and longitudinal acceleration data, among other information. They receive this data not only for their own car but also for every competitor’s car by mutual agreement. Previously, each team was spending lots of money independently capturing the radio transmissions of their competitors to get this data, so they all got together and decided to share it freely to save money.

Having all this data on hand has led racing teams to use data analytics, digital twins and artificial intelligence tools on race day to gain an advantage. They can now take real-time data coming from a car and create actionable data on the spot. Teams are looking at the other guys’ steering, brake and throttle data to see where they need to improve their own car’s performance.

During the race, machine learning and cloud computing is taking place as AI becomes incorporated into racing. For example, RCR has strategy optimization software that predicts the right call for when to pit based on how fast the tires are wearing and how the weather is changing, among other factors. Simulations like these using data from their own car and the rest of the field help RCR engineers take advantage of their strengths and opponents’ weaknesses.

So, although the 2018–2019 rules changes did bring the drivers’ skills and daring back into the equation, making for a more exciting race for the fans, the engineers are busier than ever as those rules continue in the 2020 season. CFD, FEA and multiphysics simulations, topology optimization, HPC, machine learning and AI are all part of the package. Simulation is leading the way to the checkered flag.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。