Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

“Simulation is among the core elements of digital transformation needed to revolutionize our product development. Ansys’ solutions pay off in shorter development cycles and less prototyping — key points in digitizing our R&D processes that help us take our mobility solutions in new directions.”

— Dr. Helmut Schmid, Manager, Advanced Development Department, ZF Friedrichshafen AG

ZF Friedrichshafen AG is automating development for all characteristics of electric motors related to electromagnetic, thermal, and mechanical domains. The goal is to continuously deliver software solutions and provide novel methods and tools that can be used by stakeholders all along the development chain. ZF looks to Ansys-enabled simulation frameworks and workflows to deliver sustainable solutions to individuals involved in the core development of ZF’s electric motor technology.

Challenges

To best address automotive original equipment manufacturer (OEM) requirements, ZF needed to develop electromagnetic technology with a simple functionality that extends to vehicle motion control, integrated safety, autonomous driving, and electric mobility — high-volume, novel solutions available at an affordable cost. Consequently, ZF needed to standardize the development process on both the product side and the simulation side to realize greater efficiencies and continuously deliver solutions, methods, and tools suitable for internal stakeholders at every step. Chaining different multiphysics tools together was of key importance during this process.

Engineering Solution

Ansys simulation made accessible on ZF’s local workstation and high-performance compute environments on-premises was used to shorten development times with a high degree of maturity for multiphysics simulations in electromagnetic, thermal, mechanical, and fluid domains. Various Ansys solutions were incorporated into automated workflows with standardized and modular scripts. This enabled the metamodeling needed for analyzing thousands of different designs, with a focus on different properties of the final product to achieve standardization across ZF's entire product portfolio.

Benefits

- Simulating multiple physics and domains enabled the successful evaluation of thousands of design variants to help ZF produce a hardware prototype that outperforms its current benchmark for power density at 95% system-level efficiency.

- Using Ansys Q3D Extractor in Ansys Fluent to calculate the parasitic effects and frequency-dependent characteristics of their designs as a part of a larger electronic design automation workflow resulted in an accurate model of the circuit needed to simulate circuit response.

- Passing the circuit model through Ansys Maxwell enabled a parametric (statistical) model that could then be further optimized in Ansys Twin Builder via Ansys Electronics Desktop (AEDT) to understand electromagnetic components and their effects on overall design, then create a larger model that could be further optimized to meet all necessary component requirements.

- The resulting Q3D Extractor-Maxwell-Twin Builder workflow currently supports the creation of thousands of design variations that can be benchmarked against outside products for performance, efficiency, compactness, and cost to deliver a competitive yet simple electric motor solution.

- Ansys simulation also facilitates ZF’s “blank canvas” approach to development, enabling the R&D team to freely play in the white space to figure out an entirely new principle reflected in a new product around a serious application for their customers.

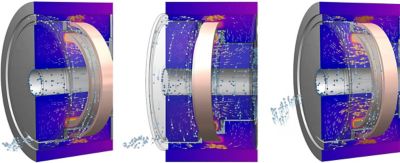

Fluid, thermal, and electromagnetic simulation of an inductive exciter unit for ZF's Separately excited Synchronous Motor.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。