Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

India is concentrating on ramping up two- and three-wheeler electric vehicle (EV) platforms. With lower additional costs from internal combustion engine (ICE) equivalents and very low running costs, customers can now choose a sustainable alternative to ICE vehicles. However, their drivetrain components were not originally made to comply with Indian environmental requirements, including thermal, vibration, and ingress protection requirements. Nhanz, with ample original equipment manufacturer (OEM) experience, front-loaded these requirements into their design and iterated different thermal combinations to create a practical drivetrain.

Challenges

The major challenge with these systems is their very low cost of system manufacturing, which eliminates the facilitation of liquid cooling. A shortage of qualified automobile fans rules out the alternative of forced air cooling. Hence, suppliers are inclined to meet requirements with practical, natural airflow within the vehicle. This is aggravated by high grade roads and heavy vehicle loads, which increases the average dissipation loss in the system.

Engineering Solution

Nhanz worked out multiple inline thermal management systems to meet technical and cost requirements using the parameters from the challenges they faced. To consider a practical scenario, all peak ratings were checked after continuous ratings were stabilized. Simulations were performed to check multiple peak operations that a system could handle in sequence. With considerable effort spent in virtual validation in different scenarios, they developed a platform which worked, as per simulation, “first-time right.”

Benefits

- Cost reduction from reduced weight in materials

- About three months saved by getting it right the first time

- 15% improved thermal performance for the same volume

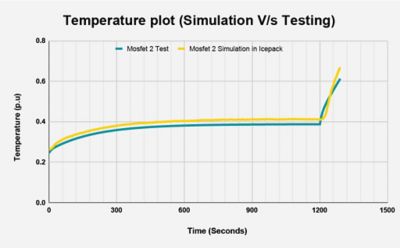

Thermal test of mosfet 2 comparison with Ansys Icepak simulation

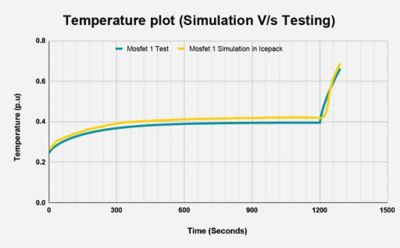

Thermal test of mosfet 1 comparison with Ansys Icepak simulation

Thermal test of mosfet 3 comparison with Ansys Icepak simulation

Ansysができること

Ansysができること

お問い合わせ

お問い合わせいただき、ありがとうございます。

当社はお客様の質問にお答えし、お客様とお話できることを楽しみにしています。Ansysの営業担当が折り返しご連絡いたします。