Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

“The students are introduced to the powerful multiphysics solver LS-DYNA and its pre- and post-processing interface LS-PrePost. The software is used to set up simulation models representing various stages of the composite design process and manufacturing phase, including part manufacturing via resin infusion (filling simulation using LS-DYNA’s ICFD solver) and mechanical testing (using LS-DYNA’s explicit and implicit structural solver) to optimize the final part for maximum stiffness. Incorporating Ansys simulation software into the curriculum provides students with a comprehensive and practical learning experience, equipping them with valuable skills and knowledge that are directly applicable to the challenges they may face in their future engineering careers either in industry or advanced studies and research endeavors.”

— Dr. Miro Duhovic, Research Manager, Leibniz-Institut für Verbundwerkstoffe GmbH

Engineering simulation based on the finite element method is perfectly suited for designing composites and their manufacturing processes. In the college course CAE With Composite Materials, taught at the Technical University of Kaiserslautern in Germany, students are introduced to simulation to gain a basic understanding of its possibilities. Ansys LS-DYNA provides an exceptionally powerful multiphysics simulation tool that enables students to simulate both the mechanical performance of their composite parts and the manufacturing method used to produce it.

Challenges

Simulation is an integral part of the composite design process and plays a crucial role in the design and digitalization of composite parts. Fiber-reinforced polymer composites are complex materials that need powerful simulation tools to design parts optimized for lightweight and maximum performance. Easy student access and the ability to trial the full power of the software over an entire semester were part of the criteria in finding a software solution.

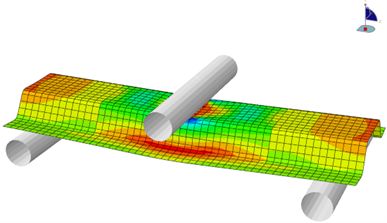

Figure 1. Simulation of the three-point-bend mechanical testing of a hat-profile composite part designed and manufacturing by students in the course

Figure 2. Physical three-point-bend mechanical testing of a hat-profile composite part

Engineering Solutions

Engineering simulation provides the important link between theory and practice and enables students to experience the results of their design decisions before taking the expensive step of physically making their part. Realistic, robust, and efficient simulations with the possibility to run even complex physics example models with limited computing resources (e.g., student laptops) was a key feature of the LS-DYNA software, along with the possibility to automate the model creation process with scripting tools like Python. It even carried out large parameter variation studies for composite materials, which are even more complex.

Benefits

The undergraduate course CAE with Composite Materials provides a highly practical, hands-on environment for students to experience real-world design, simulation, manufacturing, and testing of composite components. After completing the course, they are better prepared for their future careers by gaining experience in using industry-standard software solutions from Ansys.

The students experience the entire development chain, starting with selecting materials, designing the part, manufacturing their part in teams, and even competing with others to determine best mechancial performance. Engineering simulation with tools like LS-DYNA is seen as an integral part of this entire process.

Figure 3. Real (left) and simulated (right) vacuum-assisted resin infusion manufacturing of a hat-profile composite part

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。