Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

"In our teaching portfolio, we integrate a diverse range of Ansys tools. These simulation tools progressively build upon one another throughout the entire course. Through the strategic use of Ansys tools in teaching and our proficiency in conducting laboratory measurements for both typical mechanical and process engineering applications, students acquire enhanced skills. This improved skill set enables them to apply their knowledge more effectively to intricate technical tasks and critically assess boundary conditions for components and processes. Additionally, our teaching methods emphasize the concept of successful failure through simulation, employing techniques such as parameter studies and validation of results. This approach allows our students to evolve into more adept engineers, empowering them to develop superior products and processes."

— Frank Einicke, Dipl.-lng.(FH), Hochschule Nordhausen University of Applied Sciences

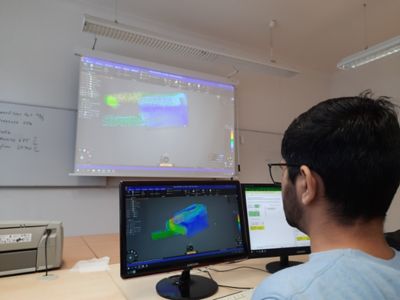

For most students at Hochschule Nordhausen University of Applied Sciences in Nordhausen, Germany, Ansys Discovery is their first experience with simulation software. In accordance with the guiding principles of the university course “Understanding Physics — Constructing Better,” students implement topics from mechanics, heat transfer, and fluid mechanics in initial design studies in Discovery’s Explore Mode. By validating the results in Refine Mode, they can evaluate the first results of product and process optimization in a time-efficient manner.

With real process investigations in the labs and additional experience with Ansys Granta EduPack and other Ansys software, students can easily create sustainable solutions and products. In general, studying applied science often inspires an interest in finite element analysis (FEA) and computational fluid dynamics (CFD), helping students become better engineers.

Challenges

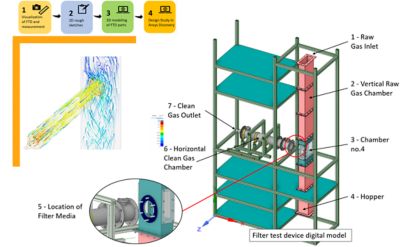

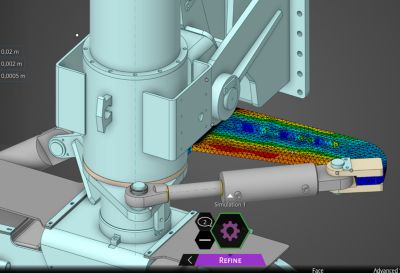

The goal for one of the last teaching simulation projects for the students was to generate a digital twin of a flue gas cleaning process in a laboratory filter test device (FTD). The filter was defined as porous media in Discovery. In a very short time, they implemented the solid assembly in Discovery modeling and simulated fluid extraction to investigate the filter and find a physical solution in Refine Mode.

During the project, students investigated pressure drop, filter inflow velocity, and flow conformity. Next, they compared the measured lab results of pressure drop and velocity values with the digital twin results. At the end of the project, students were excited about the topic of digital engineering even without having any previous simulation experience.

Digital twin of a laboratory filter test device (FTD)

Teaching computer-aided engineering in modern laboratories at Hochschule Nordhausen

Engineering Solutions

- Students used Granta EduPack to learn which material is useful for predefined boundaries, especially plastics, compounds, and additive manufacturing materials.

- Discovery offered their first experiences with direct modeling, simulation-oriented preparation of complex geometries, and still derivation.

- Discovery helped students understand the product and the philosophy of physics design.

- Ansys Workbench familiarized students with the basics of FEA and CFD and enabled them to conduct advanced investigations in process and product optimization. Students were also able to evaluate the results of mixing, heating, and printing with their own lab investigations.

- Ansys Rocky enabled students to understand the bulk material process with discrete element modeling (DEM) simulation and evaluate through their own lab investigation.

Benefits

- Discovery delivered the best experience for 3D modeling and simulation of a filter test device. Its user-friendly interface, accurate simulations, and real-time feedback were helpful for optimizing the workflow. It is the top choice for offering powerful features and ease of design for efficient engineering and design projects.

- The software was was easy to learn due to its user-friendly simulation tools combined with the possibility to quickly change parts accordingly.

- Discovery is an exceptionally user-friendly tool that simplifies the simulation process. It facilitates efficient problem solving and makes complex tasks remarkably straightforward. The software's standout feature lies in giving users the ability to make real-time changes to their designs. Overall, Discovery makes simulation tasks accessible, efficient, and responsive to design modifications.

Ansys Discovery gave students their first experience with simulation through hands-on tutorials they could follow step by step.

Optimization of a bending sword connector on a road crawler. Investigations of notch stresses and natural frequencies with modal analysis.

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。