-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

December 16, 2020

Workflow Automation Speeds Your Digital Transformation

Product design and development complexity continues to increase, extending to the system level where multiple components within products need to interact. No matter what engineering discipline you specialize in, you need to ensure your workflow is as efficient as possible to deliver increasingly complex products in shorter timeframes.

The need for process efficiency has led to disjointed workflows where individual engineers or small teams specializing in disciplines like noise vibration & harshness (NVH), thermal-mechanical-electrical analyses or safety evaluation create their own workflows. Without visibility across the many simulation processes necessary for complex product design and development, improving one discipline’s process could require a compromise in others.

Using Simulation Process Data Management for Virtual Product Development

To allow cooperation in multiphysics simulation and multidisciplinary optimization, the automation and publishing of workflows for several repetitive tasks, as well as simulation process data management (SPDM) become essential.

- Transferring results of one discipline as input into the next step of operation.

- Post-processing steps, reports and result extraction.

- Model generation tasks.

- Comparing variants to find an optimal design.

- Subsequent optimization runs with adapted constraints and objectives.

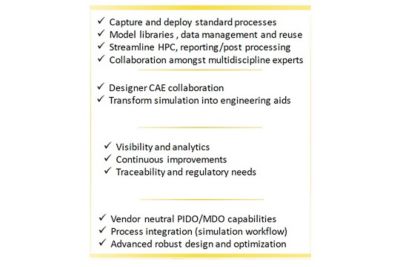

Critical success factors for digital transformation

Combine Process Integration and Design Optimization with Enterprise-Level SPDM

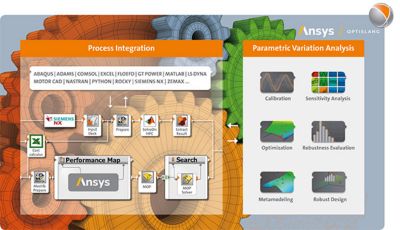

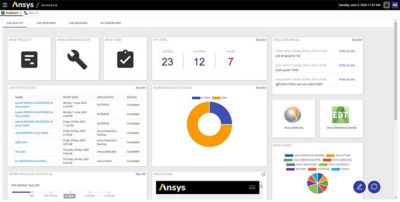

A solution to overcome the challenges involved in collaboration is the combination of Ansys optiSLang, a powerful process integration and design optimization (PIDO) solution, and Ansys Minerva, powered by Aras. Minerva is an enterprise-level solution that secures simulation data and provides simulation process and decision support to engineering teams. Together, the solutions help you capture, automate and deploy simulation more broadly across the enterprise.

While Minerva enables you to connect simulation and design teams, optiSLang connects the various tools that the team members use. This combination helps you capture, automate and deploy simulation more broadly across the enterprise. Watch this webinar to:

- Learn how to orchestrate heterogeneous tool chains and set up optimization within optiSLang for design exploration and robust design.

- Explore simulation and optimization data management and collaboration in Minerva.

- See an integrated demonstration of an optiSLang process published into Minerva as a web app.

Digital Transformation via Simulation

As more companies rely on more simulations to efficiently create innovative products, visibility across the enterprise has become critical to make the best use of the additional simulation data. With the improved collaboration made possible by combining optiSLang and Minerva, you can connect the digital thread across silos of simulation information to boost your digital transformation strategies and democratize the use of simulation throughout your company.

Using a collaborative, managed, open environment for SPDM can help you create innovative, complex products under deadline without creating rework or bottlenecks for your coworkers. The combination of optiSLang and Minerva enables:

- Faster throughput for engineering simulation workflows.

- Increased non-expert decision-making through simulation.

- Management of computer-aided engineering (CAE) goals and metrics – both quantitative and qualitative.

- The ability to leverage optimization early for exploring design options.

For more information watch the on-demand webinar: Design Studies and Process Automation with Ansys optiSLang and Ansys Minerva, powered by Aras.