-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

July 21, 2021

Will Cable Harness EMI Risk Autonomous Vehicle Safety? Find Out Before It’s Too Late with Ansys HFSS-EMA3D Datalink

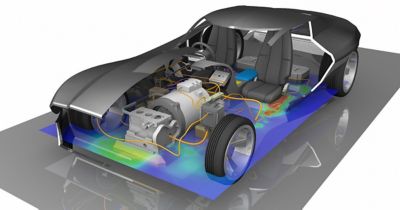

As vehicles become progressively autonomous and more safety-critical functions are electrified, product engineers are counting on simulation to address electromagnetic interference (EMI) and electromagnetic compatibility (EMC) of large, interconnected electronic systems. That includes the cable harnesses that are crucial for transmitting electrical power and control signals to the electronics within cars, ships and aircraft.

Until now, though, there’s been no easy way to accurately simulate the interaction of cables, antennas, printed circuit boards and other subsystem components on a real platform. Instead, engineers were spending months, and sometimes even years, building full platform models from scratch, without guaranteed accuracy.

All that has changed with the introduction of a datalink that integrates two leading software programs: Ansys EMA3D Cable and Ansys HFSS.

EMA3D Cable solves complex EMI and EMC challenges related to high-intensity radiated fields, lightning strikes, radiated emissions and conducted susceptibility, among other issues. It is being used to build complete models of cars and planes, including every cable. Ansys HFSS is the world’s foremost antenna design and modeling tool. Its comprehensive set of solvers allows engineers to address diverse electromagnetic problems ranging in detail and scale from passive integrated circuit (IC) components to extremely large-scale EM analyses, such as automotive radar scenes for advanced driver-assistance systems (ADAS). The datalink between HFSS and EMA3D Cable enables accurate, complex cable modeling like never before, with real-life results.

Easily Import HFSS Fields into a Cabling Solution Without Tool Hopping

Accuracy is paramount in the world of product design, especially for safety- and mission-critical devices. But in the race to be first to market or to compete with industry leaders, building the simulation solution must also be fast and affordable.

Even before the HFSS to EMA3D Cable datalink, each software package offered advantages in terms of speed and ease of use. But with the datalink making it quicker and more intuitive for engineers to import HFSS fields into the EMA3D Cable environment, the time required to build models is generally shortened by a factor of 10.

Consider this: A client had allocated years to construct their platform using a competitive simulation product, but in a matter of weeks, Ansys helped them build an accurate full platform project. That is an astonishing time savings.

Using the HFSS to EMA3D datalink doesn’t just save time over the long run, however. It’s so quick and easy to learn that even new engineers can be up and running with just a short, hour-long introductory session.

One key to productivity is the HFSS datalink wizard, which substitutes point-and-click simplicity for complex manipulation of data files. There’s no more tool-hopping. Everything is done in a single environment: engineers can capture both the electric and magnetic field information of the antenna setup in HFSS, then navigate to an exported XML file and the data shows up as a source in EMA3D Cable. When they begin the simulation, engineers can visualize not just the antenna but the field interaction with the platform. See the entire process in the video below or watch it on YouTube.

Importing subsystem component fields into a cabling solution is as easy as:

- Simulating a subsystem such as an antenna or PCB in HFSS.

- Creating an XML file containing all the electric and magnetic field information.

- Importing the XML file into EMA3D to perform a true system simulation.

In addition, the HFSS wizard automatically makes all the connections between the frequency domain solver and the time domain solver, which allows the user to simulate extremely complex antennas and PCBs in HFSS and Ansys Slwave software, and use them in a platform-level simulation in EMA3D Cable. Plotting and statistical post-processing are also automatic.

Resolve EMI and EMC Challenges Early

As the world relies more on radar, processors and other electronic systems to make life-and-death decisions, mitigating EMI and EMC issues at the earliest stage possible is imperative. So is the ability to meet stringent certification requirements, including U.S. Federal Aviation Administration certification, probably the toughest acceptance challenge of all from an engineering standpoint. Where years ago, an electronic system that failed EMC might still be accepted simply because its function was not safety critical, but that’s no longer the case. Being able to predict EMI and EMC performance is essential; if you don’t have a platform that can pass EMI/EMC, you can’t sell those cars or fly those planes or sail those ships.

Simulation with the powerful combination of EMA3D Cable and HFSS enables resolution of EMI and EMC challenges at an early stage. And with the HFFS to EMA3D Cable datalink, delivering high-performance, safe and compliant designs is faster and easier than ever. Learn more in this on-demand webinar: Ansys 2021 R1 Update: EMA3D Cable Faster EMC Solving for Large Systems.