-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

August 7, 2020

Vantablack Optical Simulation: From Space to the Road

A BMW X6 coated in Vantablack

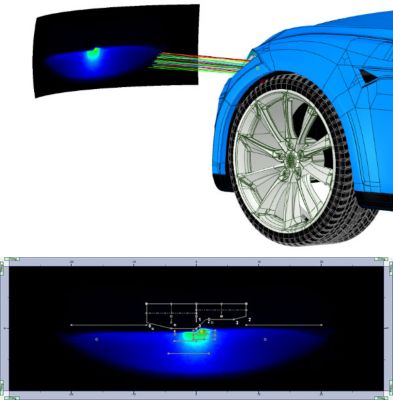

Material choice in the design process plays a vital role in product performance and safety, as shown in the image below. This simulation result demonstrates just how powerful Vantablack® can be for solving stray light issues. But what exactly is Vantablack?

Simulation results comparing a regular black coating and Vantablack applied on a windshield camera light trap

Vantablack is the brand name for a new class of super-black coatings. The coatings are unique in that they all have hemispherical reflectances below 1% and also retain that level of performance from all viewing angles. The original coating, known just as Vantablack, holds the independently verified world record as the darkest man-made substance. It was originally developed for satellite-borne blackbody calibration systems and achieved space heritage in 2015, eliminating the sun’s glare in satellite positioning systems.

Vantablack coatings have unrivalled absorption from ultraviolet frequencies out beyond the terahertz spectral range. The properties of these coatings are being exploited for applications such as deep space imaging, automotive sensing, optical systems, art and aesthetics.

“The ability to withstand shock and vibration during space launch and extremes of temperature whilst maintaining virtually perfect absorption makes Vantablack a first choice for a wide range of automotive applications,” says Michael Stellmacher, Business Development Director of Surrey NanoSystems. “Vantablack coatings eliminate reflectances in head up displays and camera glare shields. They significantly boost the performance of lidar sensors and are used to control stray light and to create unique designs in automotive lighting.”

How can a company predict the impact of such a material without investing too many resources in prototype testing?

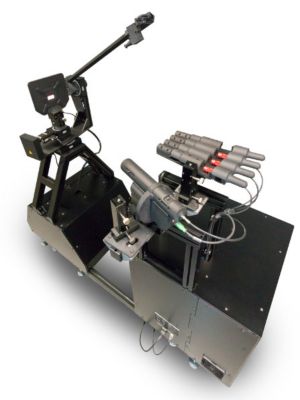

Ansys laboratory optical measurement device

Perform Stray Light Analysis With Specific Materials

Ansys offers optical measurement devices to acquire your material optical properties, whether in the laboratory or directly in the field with a handheld device. The acquired optical properties — such as .brdf (bidirectional reflectance distribution function) or .material files, for example — are used as inputs for the optical simulation.

It is critical to test highly specific materials that have a behavior of their own. You don’t want to use generic optical properties as simulation input. You need the exact model of what will be applied, and that can be attained via optical measurement devices and simulation. With optical simulation, you can also test multiple material combinations without referring to a costly physical prototype.

This native combination of hardware and software is one of the keys that make Ansys Speos optical system design software so reliable. Both hardware and software — including the data post-processing algorithm preparing the measured data for simulation — are designed to achieve best-in-class optical simulation.

Vantablack Stray Light Use Case Scenarios

Let’s take headlamp design, for example. Imagine you fail a regulation test because tolerances weren’t considered correctly in the design. The problem has to be solved — a redesign after model freeze is out of the question.

Using the Light Expert function in Speos, you can precisely determine the face of the geometry reflecting too much light and causing the regulation failure. Once you have determined the cause of the stray light in the headlamp, you can simulate the amount of surface that has to be coated with Vantablack to remove this parasite light. You can save a project from failure without changing your design or your core material choices.

But how about involving Vantablack in the early design stage, avoiding such problems close to production, or after production has started?

A simulation setup in Ansys Speos (top) using low-beam regulation measurements (bottom).

Using Speos, you can make Vantablack a key feature of the design, right from the start. Let’s say you’re designing a windshield camera. Testing different shapes and different materials is fast and cost-effective with Speos, giving you more options to find the right design in the early phase of development. You can simulate different times of day, for example. The critical sun positions can be determined and serve as a reference to perform follow-up tests, ensuring the system will perform in all conditions.