-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

May 4, 2021

Take Your Engineering Simulation Workflow to the Next Level

A day in the life of a simulation engineer is full of data: design requirements, project goals, current and previous computer-aided design (CAD) files, current and previous simulation files, materials information, spreadsheets, text files and all the communications surrounding them. Working with the right data is critical to an efficient workflow, but with all the different stakeholders involved in product design and development, how do you know where the right data is? And, equally important, how do you know whether that data has been updated, by whom and why?

When data is scattered across the company and its suppliers, it’s difficult to ensure that your intellectual property is secured, proper version control practices are being followed and there is traceability back to the design requirements. Without this context around the data, you may find it faster to do the job again, rather than try to find the missing pieces of information or risk using outdated data. Of course, this rework is not only inefficient for you, but creates the potential for even more data confusion for your colleagues and increases the risk of error.

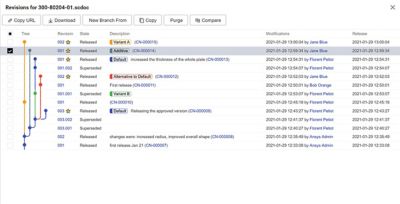

Ansys Minerva, powered by Aras, features revision tracking, which enables you to keep track of data.

It’s not enough to store all the data you need in a single location. It must be easily searchable with at-a-glance visuals to make it easy to use by coworkers with various levels of engineering experience. Because every company is different, a simulation process and data management solution should be easy to configure so that it follows your own review process and flexible so it can account for change orders. Finally, it should be open to any data format or tool, while still providing full traceability.

In short, your simulation data should be:

- Visible

- Accessible

- Linked

- Reliable

With Ansys Minerva, powered by Aras, you’ll be able to secure critical simulation data, provide process and decision support, and deliver immediate benefits by connecting simulation and optimization solutions to your existing ecosystem of tools and processes. Because Ansys Minerva is available for both on-premise and cloud deployment, it connects team members regardless of geography and functional silos.

Improve Data Management Connectivity

Take a look at how Ansys Minerva helps you keep track of evolving simulation models and provides results in context by watching the “Improving Model Data Management with Ansys Minerva, powered by Aras” webinar. In the on-demand webinar, you’ll get to see demonstrations of how Ansys Minerva is used to quickly find information and ensure files are synchronized.

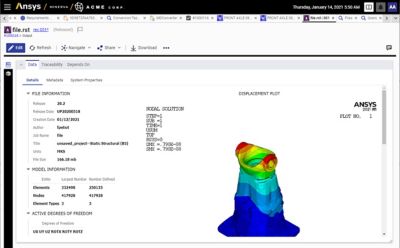

Dependency tracking in Ansys Minerva provides context to data, showing you how it was created and by whom.

In the first demonstration, I play the part of an engineer who has been given the name of a final simulation report and asked to find the original CAD file. It’s easy to imagine this request coming in late on a Friday afternoon. I walk you through a quick, filtered keyword search in Ansys Minerva to quickly find the final report and then trace the history of the simulation all the way back to the original CAD file. A task that might have taken hours to complete – if it could be completed at all – is done in minutes and the engineer’s weekend is saved.

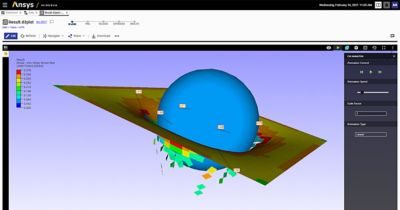

In another demonstration, I take on two roles: a CAD designer who updates a parts library with a new model he just received from a supplier; and a simulation analyst who will use that new geometry in a prior simulation. After quickly finding and updating the simulation with the new part, I show how to make the new results report available to stakeholders via a browser-based, visual interface. I also show how the traceability is automatically updated as well to illustrate how Ansys Minerva supports a streamlined workflow.

Ansys Minerva reports can easily be shared and viewed in standard web browsers.

Check out the free, on-demand webinar for the demonstrations that show how Ansys Minerva can help you get control of your data.