ANSYS BLOG

August 29, 2023

Dismantling Solar Storage Roadblocks: Simulation Helps Harness the Power of the Sun

Renewable energy sources are expected to play a critical role in the global effort to achieve net-zero emissions by 2050, and solar power is chief among those alternatives, largely because it’s inexpensive to implement and can generate electricity in any climate.

But before solar energy can be counted on to help meet internationally agreed upon decarbonization goals — not to mention supporting the three-fold increase in energy consumption that the U.S. Energy Information Administration (EIA) predicts will happen over the next 25 years — two things will have to happen. There will have to be a massive increase in solar power adoption across the globe and significant advancements in generation and storage technology.

In particular, the world will need to overcome the lack of sustainable utility-scale storage, which factors into preventing the widespread uptake of solar energy.

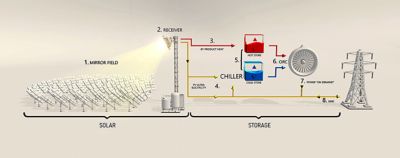

Australian renewable energy company RayGen has taken aim at that problem, developing what it says is the world’s largest long-duration energy storage project near Carwarp, Victoria. The project uses 1,200 stand-mounted concentrating mirrors called heliostats to track the sun, generating electricity via high-performance solar photovoltaic (PV) modules and then storing byproduct heat in a water pit the size of four Olympic swimming pools. The heat is later converted to dispatchable electricity. The project is designed to deliver four megawatts (MW) of solar generation and 50 megawatt hours (MWh) of storage, producing electricity on demand via a 2.8 MW Organic Rankine Cycle (ORC) engine, for offtake by Australia’s largest utility company, AGL Energy.

RayGen uses Ansys simulation software to model numerous elements of their power plant including the heliostats, the receivers that capture the focused solar energy, and components of the storage system. They work with LEAP Australia, Ansys Elite Channel Partner for Australia and New Zealand, to access Ansys Fluent, Ansys Mechanical, and Ansys Zemax OpticStudio through the Ansys Startup Program.

RayGen’s energy storage project near Carwarp, Victoria, Australia

Energizing the Grid, Day or Night

You’ve probably heard critics suggest solar energy is good only when the sun is shining, and there’s actually some merit to their concern. While homeowners and businesses can capture and store solar energy by way of large, expensive batteries that supply power when the sun isn’t out, there hasn’t been much in the way of effective, low-cost storage for larger solar arrays like grid-connected solar farms.

Without sufficient storage capacity, many grids are overloaded at midday, causing service providers to rein in their solar generation. As soon as the sun sets or the sky turns overcast, shading the panels, power companies must revert to traditional generation methods. Consequently, the lack of adequate solar energy storage for evening use — when consumer demand is usually at its highest — remains one of the major limitations holding solar technology back from mass adoption.

RayGen may have finally dismantled this roadblock.

As part of their drive to accelerate the transition to renewable energy, the Melbourne-based company has developed an improved approach to solar power — one that they say energizes the grid at all times of the day and night, even when weather conditions are poor.

Their technology is based on the concept of “pit thermal energy storage,” a technology that RayGen borrowed from the district heating network in Europe, where countries like Denmark use solar thermal energy to heat up large bodies of water during the summer. In the winter, utilities circulate that hot water through the district heating network to warm peoples’ homes.

“It’s an established technology that we adopted for our application,” says Kira Rundel, Head of Strategic Projects at RayGen. “It allows you to store hot water for long periods of time with very minimal losses. So, we store water at 90 °C for days, weeks, months at a time and we lose only about 5% to 10% of that thermal energy over the course of six months. It’s an extremely efficient way of storing energy.”

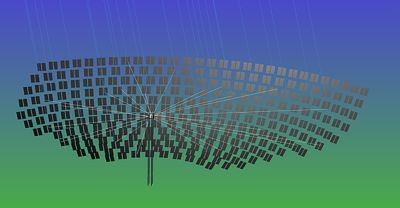

Ansys Zemax OpticStudio simulations ensure that the heliostats always deliver as much light and heat to their receivers as possible.

Following the Sun

A sheep pasture that’s roughly a six-hour drive northwest of RayGen’s home office is the site of the company’s flagship project: a next-generation solar power plant and electrothermal energy storage (ETES) system. By pairing what RayGen refers to as their “PV Ultra System” with a water-based storage system, the company has successfully created a first of its kind, high-efficiency facility for both the generation and storage of energy derived entirely from the sun.

The PV Ultra System is a large field of heliostats that concentrate sunlight toward a single, high-capacity receiver. The heliostats are calibrated to track the sun’s position in the sky and to redirect the highest possible amount of solar energy to the receiver. Sitting atop a tower high above the heliostat field, the receiver captures the concentrated sunlight with the help of hundreds of high performance III-V GaAs solar modules that are approximately two thousand times more powerful than traditional silicon PV panels, under concentration. This configuration allows the PV Ultra System to convert the captured energy into both electricity and heat with 90% efficiency.

RayGen captures that heat — so intense it could melt steel — by circulating cooling water through the solar cells. The water leaves the solar cells at about 95 °C and is held in a massive, insulated water pit, which has the capacity to store up to gigawatt hours (GWh) of energy.

In a concurrent process, a portion of the electricity generated by the PV Ultra System branches off to chill water contained in a second pit, located next to the hot pit. By maintaining a 90 °C temperature differential between the hot and cold water pits, this sector of the RayGen solar power plant has the capability to power an ORC engine that generates and delivers on-demand energy directly to a connected power grid in the same fashion as a geothermal plant. The system has a round-trip efficiency of 70-80% at less than half the cost of a battery-based storage system.

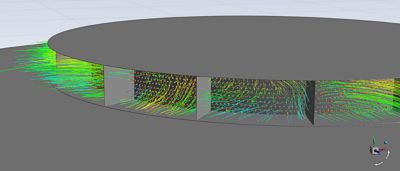

Ansys Fluent simulation of the flow of water through the diffuser in its original design, showing non-uniform flow patterns.

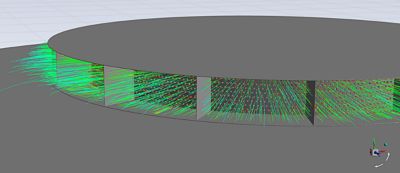

Ansys Fluent simulation of the flow of water through the diffuser in its optimal design, showing more uniform flow to maintain the temperature gradient in the hot and cold storage pits.

From Simulation to Success

Developing a system as complex as RayGen’s solar power plant means taking into consideration everything from electronics and hydrodynamics to the movements of the Earth and sun. While it’s conceivable that capable engineers could design such a facility with just pen, paper, and know-how, without the aid of digital simulation it would be a monumentally long, arduous, and costly task.

By employing solutions from Ansys, RayGen’s engineers found a faster way.

Optical Simulation

Considering that the sun’s rays reach the Earth from different angles and with varying intensity throughout the day and over the course of a year, RayGen turned to OpticStudio to ensure that the heliostats always deliver maximum light and heat to their receivers. Without numerical modeling in Zemax, it would have been next to impossible to lock in the best design for each heliostat field.

Thomas Evans, Mechanical Engineer at RayGen, estimates that “using Ansys simulation has saved us months of design time and a considerable number of man-hours. Plus, instead of requiring significant capital expenditure on multiple prototypes and testing phases, we can be confident that we are progressing on the right track, both optically and mechanically, before we commit to constructing anything.”

The optical simulation and analysis capabilities of OpticStudio enable RayGen engineers to run thousands of simulations comparing the effects of adjusting multiple variables such as the size, spacing, and curvature of the heliostat array, as well as its distance from the receiver and the angle of the individual mirrors. By integrating solar data with these simulations, RayGen was able to calculate the optimum arrangement of the entire array and the automation required to maintain each heliostat’s optimal orientation over time.

Optical simulation played a part in designing the receiver as well. At each of the receiver’s four sides, a flux modifier works to widen the receiver’s aperture, capturing any stray light coming from the heliostats and reflecting it back onto the solar modules within it. By incorporating this factor into the system’s design parameters, RayGen’s engineers were able to secure the highest possible concentration of solar energy at the receiver — an amount 1,000 times greater than the sun itself.

A schematic of RayGen’s electricity generation process, including a field of heliostats (mirrors), a receiver, the hot and cold water storage pits, and the Organic Rankine Cycle engine

Structural Simulation

Heliostats must perform year-round whether it’s hot or cold, windy or calm, raining or desert dry, meaning material properties must be able to withstand considerable climate variations. At the same time, for the PV Ultra System to succeed as a practical, replicable energy solution, the world will need many heliostats, so the economics must be right. Functionality, adaptability, and per-unit cost are all drivers when it comes to selecting materials.

Using Mechanical to analyze worst-case structural loads, RayGen engineers devised a final heliostat design that requires minimal steel but can withstand adverse weather without becoming compromised or losing its bearing on the receiver.

Computational Fluid Dynamics Simulation

Fluent helped RayGen engineers develop multiple aspects of their thermal-hydro energy storage system, which comprises two thermally insulated water pits capped by lids — one filled with hot water and one with cold. Fluent computational fluid dynamics (CFD) models optimized the water flow through the copper cooling system located behind the solar modules to keep them at an acceptable operating temperature. The resulting hot water is then delivered to the hot water storage pit.

Simulation also enabled engineers to design the large circular diffusers at the inlets and outlets of the thermal-hydro system’s hot water storage pits. The diffusers are used to maintain the thermocline within the pit by diffusing the incoming water in a way that preserves the water column’s temperature stratification boundaries, which are critical to the storage pit’s proper function.

“We have to diffuse water into the pits in a very uniform and low-velocity way so the hot and cool water doesn’t mix and disrupt the thermal stratification,” says Derek Scott, Product Development Manager at RayGen. “We used Ansys Fluent to determine the optimal design of the diffuser to prevent mixing. What we don’t want is a kind of uniform ‘hot-ish’ pit of water; our process requires access to very hot and very cold water.”

After calculating the required size of these diffusers to create an initial digital model, RayGen engineers used Fluent to determine the optimal diameter and spacing of their inlet ports, and to fine-tune the design for their internal baffles and flow screens. Simulations of many design variables on this component led to a final design that allows water to flow uniformly and at the ideal velocity, eliminating the turbulence and reverse flow generated by earlier diffuser models.

The Future is Bright ... and Renewable

While RayGen envisions similar solar-plus-storage power plants across Australia and, ultimately, the rest of the globe, its proving ground at Carwarp — with its four heliostat fields and receiver towers producing 1 MW of solar energy apiece — lays claim to the title of largest long-duration energy storage project built to date. But RayGen has already announced the site’s scaled-up successor. At a location in South Australia, the company plans to erect a multiple-hundred MW plant backed by turbine generation and GW hours of storage duration.

Learn more about how Ansys simulation solutions enable a safe and reliable transition to a lower-carbon energy mix that will more sustainably meet the world’s growing and insatiable demand for power.