-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

November 12, 2020

Simulate Flight Control Systems With Embedded Software in the Loop

You may have heard of battery-powered drones being used to deliver packages, or air taxis being developed to ferry people from place to place in busy cities, or electric planes used to revolutionize short-haul and middle-flight use cases. We’ve covered how engineers at both Zunum Aero and magniX are using simulation software to connect communities via electric flight, for instance. With the challenges inherent in new electric air mobility concepts, engineering tools are crucial for efficiently designing and simulating complex systems.

Software is a huge part of any new transportation design. Complex systems like electric aircraft require a holistic approach to achieve system-level simulations with embedded software in the loop.

System simulation is key in the early design phases of an electric air mobility project, especially to analyze and predict electro-mechanical system behavior. It is a powerful means to push new air mobility technology further in terms of performance and safety. It can apply to flight control, braking control, engine controls and battery management systems, but also to embedded human machine interfaces (HMIs).

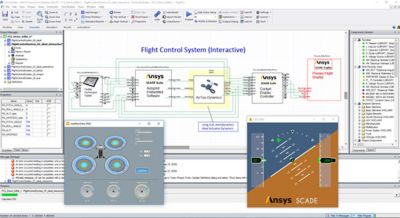

The video shows an interactive runtime simulation session with Ansys SCADE and Ansys Twin Builder with the control and human-machine interface software executed in real time in closed loop with the vehicle model.

Closed-loop simulation is more accurate when used with a software in the loop (SiL) approach. In this approach, the “real-time” embedded software, which already relies on rigorous and safe implementation of control laws, can be included in the simulation environment — including including the aircraft dynamics that are modeled as high-reliability multiphysics models.

A runtime PC based simulation session of Ansys Twin Builder with Ansys SCADE

applications executed through a Functional Mock-Up (FMU).

Simulation and Software in the Loop

The interoperability between Ansys tools for embedded software and system simulation is key to achieve such SiL simulation, and this is possible with Ansys SCADE and Ansys Twin Builder through the Functional Mock-Up (FMU), which is a free standard interface between components. The FMU can apply to control software as HMI software.

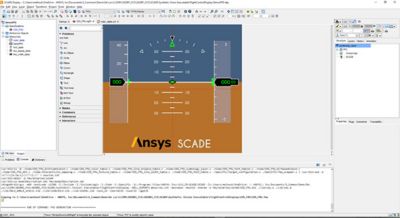

The Ansys SCADE Display integrated design environment for human

machine interfaces and automatic code generation

Additionally, software in the loop is useful for system architecture design. It is also useful for software and safety requirements refinement when considering the different operational mode of a vehicle (e.g. nominal or degraded mode) or considering several flight path scenarios with different failure conditions. For each failure scenario, engineers can analyze the controller’s responsiveness and the aircraft stability, and then tune the system parameters.

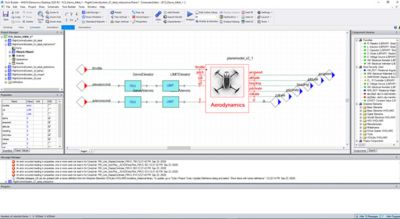

The Ansys Twin Builder design environment for multiphysics modeling of a

vertical takeoff and landing vehicle and its environment using Library blocks

A rapid prototyping solution is also possible with SCADE via FMU to provide scenario inputs to the simulation, either manually through a graphical usr interface (GUI) with pre-defined, built-in widgets or by sending flight path data directly from the Twin Builder model.

A screenshot of the Ansys SCADE Rapid Prototyper design environment

enabling the design of an interactive simulation panel for data visualization and input signal transmission to the Ansys Digital Twin.

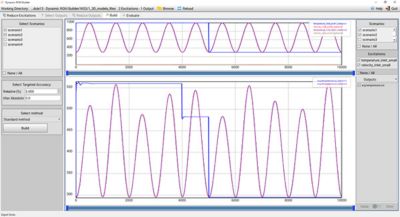

With SCADE and Twin Builder, system engineers have an efficient environment to iterate with software and control engineers as they simulate the results of plotting different aircraft data such as the speed, altitude or heading and analyze the system’s behavior.

An Ansys Twin Builder simulation plots flight data, showing a simulation iteration result.