-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

Today’s product makers are under significant pressure to accelerate development cycles and more quickly bring products to market. At the same time, products are becoming more complex. Smart, connected functionality and advanced software have become staples of products, ranging from cars and industrial machinery to kitchen appliances.

Simulation solutions have empowered companies to develop such products more efficiently. Simulation’s many benefits include reducing reliance on costly physical prototyping and testing, improving product quality, and shortening product development timelines. But simulation also produces copious amounts of data. Collecting, storing, accessing, and sharing this data efficiently across the product life cycle remains a challenge. Many organizations use product life cycle management (PLM) or product data management (PDM) solutions to manage simulation data. Such tools, however, lack the functionality that these companies need to optimize simulation data management and processes. Increasingly, product makers are turning to simulation process and data management (SPDM) solutions to further accelerate and improve the approach to product development.

To better understand the simulation data management challenges that engineering and manufacturing organizations now face and how SPDM solutions address their concerns, research firm Lifecycle Insights conducted the “2024 Simulation Data Management Study.” This market analysis of SPDM surveyed 200 companies and included interviews. Findings indicate that the tools and processes used by many companies to manage simulation data are insufficient for their needs. The report also suggests that SPDM solutions deliver capabilities that improve product development by enabling companies to extract maximum value from their investments in simulation.

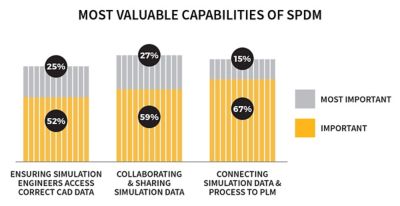

Study participants say simulation process and data management (SPDM) provides several valuable capabilities to product developers related to finding and sharing accurate, up-to-date simulation data.

Conventional Simulation Processes Are Inefficient

Simulation solutions are critical to the product development process across industries. In fact, 100% of study respondents report using simulation in product development. But using simulation and maximizing its impact are different things. Because products are becoming more complex, material costs are growing, and the pressure to bring products to market more quickly is increasing, it’s more important than ever to maximize the efficiency of the simulation process. Too often, however, simulation data is managed inefficiently. As a result, companies struggle to find, access, and share vital information with key stakeholders. Today’s product developers require a more comprehensive solution that enables better simulation data management.

SPDM Solutions Maximize Simulation’s Value

Rather than relying on PDM or PLM solutions, which are ill-suited for managing simulation data, engineering organizations must use SPDM solutions that are tailored to their needs. SPDM solutions address the limitations of PDM and PLM tools, enabling companies to accelerate product development and maximize return on investment from simulation. In many cases, that investment is significant: 77% of study respondents say their companies annually spend at least $10 million on simulation while 37% annually spend at least $50 million.

Incorporating SPDM

Simulation plays an important, ongoing role in improving product development in every industry. The kinds of improvements that simulation enables — reducing prototyping and testing costs, shortening design timelines, and increasing product quality — are crucial for companies as they work to keep pace with competitors in complex marketplaces. Unfortunately, too many companies undermine their own efforts by managing simulation data without an optimal way of doing so.

But when organizations integrate a dedicated SPDM solution with their existing PLM software, they can further accelerate the product development process, more effectively use simulation throughout the product life cycle, reduce communication errors, and maximize the return on their substantial investment in simulation.

Companies seeking to achieve these kinds of product development improvements should do the following:

- Examine the company’s current product development process and how effectively it manages simulation-related data and processes.

- Identify broken links in the simulation processes and data in the existing digital thread to determine whether those processes and data are connected throughout the product life cycle.

- Implement SPDM and integrate it with the company’s current PLM solution to ensure that simulation is available throughout the product life cycle.

For more information, read the “2024 Simulation Data Management Study.”

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.