-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

Ansys Blog

November 1, 2019

Material Selection and Simulation Are Powerful in the STEM Classroom

Engineers understand that shape and material selection are critical to the optimal design of structural parts, such as I-beams.

Science, technology, engineering and math (STEM) students, however, might not know why certain shapes or materials are advantageous for a given situation.

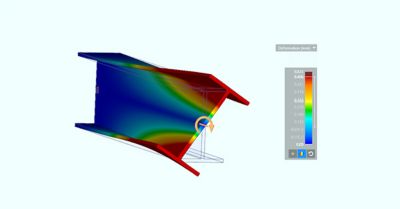

A beam’s torsional strength is dependent

on its shape and material selection

Material properties (such as stiffness and strength) and the beam shape (dimensions, second moment of area and shape factor) must be fully understood when making design choices.

CES EduPack, available in the Ansys Granta family of material intelligence software, can help STEM students learn about material properties and structural sections. For instance, when CES EduPack is combined with finite element analysis, through Ansys Mechanical or Ansys Discovery, students can explore the complex interactions between a design’s shape and material selection.

Tools for Complex Material Selection and Shape Optimization

The number of beam shape and material combinations are vast; where do engineers begin when making design decisions?

The front face of structural shapes

CES EduPack contains the structural information of various beams created by common shapes and materials, including (but not limited to):

- Shapes

- I-beam

- L-section

- Hollow circular column

- Circular column

- Materials

- Structural steel

- Extruded aluminum alloy

- Pultruded glass fiber reinforced polymer (GFRP)

- Wood

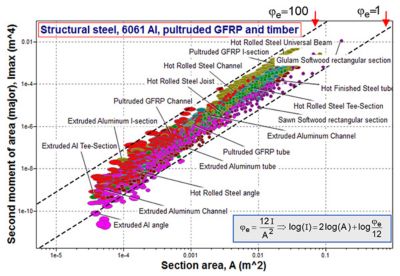

CES EduPack can compare various structural shapes and materials in one plot

Through advanced plotting capabilities, CES EduPack can be used to compare different structural materials. However, the shape factor needs to be considered to make a proper material selection. Though the software can account for some shape parameters (such as second moment of area and section area) some dimensions and design parameters will still need to be determined.

Finite element analysis (FEA) is a technique that simulates a structure’s response to specific loading conditions. During the design process, engineers can create computer-aided design (CAD) drawings and simulate the loads to understand a part’s stress concentrations and deformations. This gives the engineer detailed material requirements based on all of the beam’s dimensions and design parameters. These simulations can be performed using Mechanical and Discovery Live.

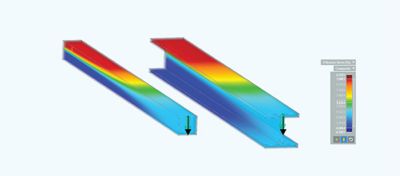

Ansys Discovery Live simulation compares the stress concentrations

of two beams with equal cross-sectional areas under equal loads

The accuracy of simulations depends on the quality of the material property information. However, gaining access to accurate material property information can be challenging. Therefore, the best way to understand the design and material selection of a structural beam is by combining the power of CES EduPack and FEA.

To see a practical example that can be used in a STEM classroom, read the case study: Material Properties and Structural Sections.