-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

April 2, 2019

Designing an Electric Car Battery Pack to win the Pikes Peak World Record

Racing fans from around the world were in awe when the Volkswagen ID. R broke the 8-minute threshold at the Pikes Peak International Hill Climb. Currently, the electric race car holds the overall record for the course at 7:57:148. Not bad for a vehicle running on an electric car battery pack.

As amazing as this feat is, the story of how Volkswagen Motorsport designed the electric race car is equally fascinating.

The Volkswagen ID. R is the only car to complete Piles Peak in under 8-minutes.

Volkswagen Motorsport had only nine months to design, test and build the car before race day. The goal was to beat the electric vehicle record. The team thought it would take at least one more year before they could beat the fleet of internal combustion engine (ICE) race cars that have taken on the course.

However, with the help of Ansys Twin Builder, Volkswagen Motorsport was able to make it to race day and negotiate the 156 curves of the 12.42-mile course 16 seconds faster than any other car ever had — including ICE race cars.

Why Volkswagen Motorsport Is Focusing on Designing Electric Car Battery Packs

Back in 2017, Volkswagen decided to make a big splash about its long-term strategy to focus on electric vehicles by 2018.

What better way to turn heads than to have Volkswagen Motorsport design an electric car battery pack that could beat the competition at Pikes Peak?

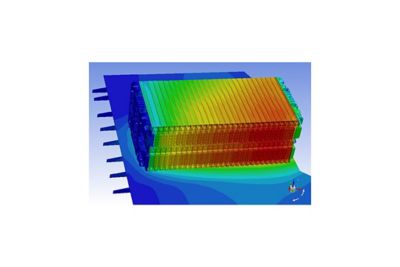

Thermal simulation of a battery module

To save time, the motorsport team opted to use the body of the Norma M20 for the car’s chassis. The team stripped out the ICE engine and found that the space for the electric car battery pack was still a little tight.

Ansys offered a helping hand to design and validate an electric car battery pack, that could fit into the Norma M20, using Twin Builder. Volkswagen Motorsport was keen to join forces.

See why Volkswagen Motorsport aimed to break the Pikes Peak record and how they pulled it off so quickly.

Designing an Electric Car Battery Pack Using Twin Builder

Volkswagen engineers needed an electric car battery pack that could get the team up Pikes Peak with power to spare. But it needed to fit the given chassis and target weight. This required a series of simulations, to determine the cell selection, battery pack size, battery cooling and charging efficiency.

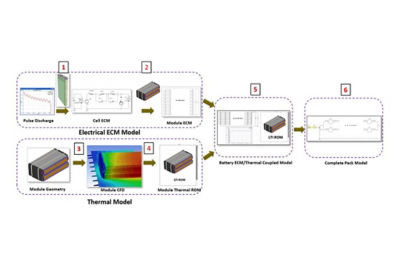

The six-step multiphysics simulation approach to design electric car battery packs using ANSYS Twin Builder.

Volkswagen Motorsport and Ansys deployed a six-step multiphysics simulation approach using Ansys Twin Builder. The simulations optimized, tested and validated the electric car battery pack’s electrical and thermal properties.

To learn how these simulations were done from Volkswagen Motorsport’s head of CAE Department, Benjamin Ahrenholz, read, Peak Performance for an Electric Vehicle. Or, attend the webinar: Volkswagen Motorsport Presents: Battery Simulation - An Essential Technology for the ID. R at Nürburgring and the Record at Pikes Peak.