-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

January 11, 2019

How CFD and Structural Simulations Can Optimize an FSAE Car

If a team is going to rank high in a Formula SAE (FSAE) race, then it must optimize its car. The only way to do this in time for race day is to iterate the design with the help of simulation.

This is a valuable lesson learned by Zuura Formula Racing (ZFR), the FSAE team from the Vellore Institute of Technology (VIT) in Chennai, India.

Zuura Formula Racing’s ZFR-06

The team’s car, the ZFR-06, ranked seventh overall and won the static design portion at FFS India 2018. ZFR notes that a series of structural and computational fluid dynamics (CFD) simulations were key to securing these accolades.

Optimizing the Aerodynamics of an FSAE Car

ZFR performed CFD studies to optimize the aerodynamics of the ZFR-06.

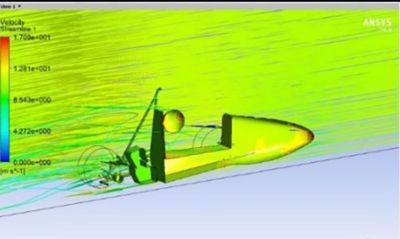

Flow streamline simulation of the ZFR-06

ZFR used the data collected by the CFD analysis to better understand the airflow around its car. The team then used this information to iterate the chassis of the car and minimize the drag calculated by the simulation.

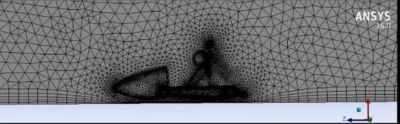

Ansys Meshing was used to mesh the ZFR-06 for the CFD analysis. The wind tunnel simulation was then performed in Ansys Fluent.

A CFD mesh of the ZFR-06

CFD Optimizes the Airflow to the Engine of an FSAE Car

ZFR also performed internal CFD simulations to optimize the air flowing through the restrictor plate toward the engine. The team aimed to reduce the pressure loss and maximize the mass flow rate across the part.

The CFD analysis, performed in Fluent, informed ZFR about the behavior of the airflow and how to optimize the restrictor.

CFD Simulations Optimize the Engine Cooling of an FSAE Car

CFD simulations also helped ZFR optimize the car’s engine cooling system. For example, the team used side pods that duct air around the radiator to maximize heat transfer.

ZFR used Fluent to better understand the airflow and make important design decisions based on the location and shape of these side pods.

Structural Simulations Optimize the Suspension of an FSAE Car

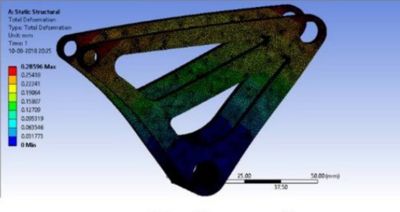

Finally, ZFR used structural simulation to optimize the strength-to-weight ratio of the ZFR-06’s suspension.

The suspension needs to be as light as possible, but it also needs to survive all the loads it could experience on race day.

ZFR simulated all of the suspension’s components using Ansys Mechanical.

Structural simulation of a bell crank from the ZFR-06

The simulations enabled the team to shave weight from the suspension’s parts while maintaining an appropriate factor of safety.

Clearly, the information ZFR gathered from its Ansys simulations were a fundamental part of its success.

As for other FSAE teams interested in using Ansys software, check out the software sponsorship program.

"I really appreciate the software sponsorship given by Ansys,” said Sudeep Kumar, the student design and simulation engineer at ZFR. “It allowed our team to move forward with the confidence gained through Simulation oriented design."

As part of the sponsorship program, students receive free software, tutorials and technical support.