-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

November 2, 2023

Boost Sustainability Through Material Intelligence and a Digital Thread

With sustainability concerns impacting industries around the world and demands to meet more rigorous environmental standards, material intelligence is more important than ever. What is material intelligence? In simple terms, it is the data, information and context for the materials being used across a business. This could include information about the properties of materials, including physical, chemical, or mechanical components, or details on the materials testing program. This intelligence enables organizations to understand and select the most suitable, functional, and environmentally compliant materials for their needs. With this knowledge, companies can select more eco-friendly materials, and, in some cases, reduce material usage by making better choices.

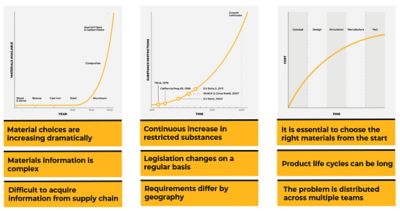

The materials “triple challenge” for sustainability

This global call for efficiency and greater sustainability has led to a digital transformation across the manufacturing industry. Companies are adopting simulation and other computer-aided engineering (CAE) and computer-aided design (CAD) tools to not only reduce physical testing and prototypes but to gain critical insights, improve design, increase team connectivity, and bolster production.

Ansys Granta MI Enterprise is a powerful materials information management solution that helps organizations make informed decisions about materials, improve collaboration, enhance compliance, reduce costs, and drive innovation during product development and manufacturing processes. At the same time, Granta MI’s seamless integration with other products and existing workflows helps companies build a reliable digital thread throughout their organization, which maximizes efficiency, increases sustainability, and supports digital transformation.

Optimize Your Materials Workflow

Granta MI is a comprehensive materials management platform designed to address the complex and critical needs of organizations in various industries, including aerospace, automotive, healthcare, and others.

Some top benefits of Granta MI include:

- Centralized materials data

- Materials traceability

- Data integration

- Material selection and optimization

- Cost reduction

- Regulatory compliance and risk management

- Sustainability and eco-design

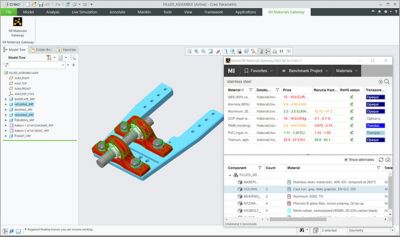

With Ansys’ materials solution, organizations can consolidate their materials data into a single, central repository. This ensures that critical information about materials — including properties, specifications, and test data — is easily accessible to all team members. The platform can also trace the use of materials throughout the product life cycle, ensuring transparency and accountability. Traceability is valuable for quality control, recalls, and audits. In addition, Granta MI integrates seamlessly with other software systems, enabling efficient data exchange across teams that streamlines workflows and reduces duplication.

Two of the platform’s most sought after features are material selection and optimization. Engineers and designers can access a wealth of data to make smarter material choices, which reduces design errors, product failures, and overall costs, while targeting sustainability goals and complying with regulatory environmental standards.

Regulatory compliance is a growing responsibility for organizations in nearly every industry. Ansys’ materials solution offers a structured approach to documenting materials information, which helps organizations meet requirements and demonstrate compliance. In relation, the platform mitigates risks by identifying materials of concern, such as substances with regulatory restrictions or potential health risks. Similarly, material intelligence can provide information on the energy and carbon emissions associated with certain materials during product development, design, manufacturing, and packaging. This awareness helps organizations make selections that minimize greenhouse gas emissions and energy consumption.

Create a Materials Digital Thread

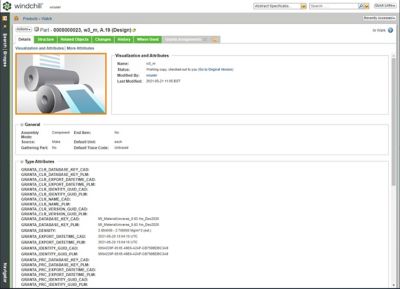

Through its seamless integration with other tools, Granta MI makes it easier to create a materials digital thread. But what is a digital thread and why would an organization want to create one? Essentially, a digital thread is a framework that enables the flow of data, in this case materials data, between the digital and physical environment to develop an interconnected workflow. Consequently, a digital thread increases traceability, accountability, collaboration, and productivity across teams. In the same manner, a streamlined and cohesive workflow increases efficiency and facilitates smoother data exchange, which reduces manual data entry, errors, and redundancy. In effect, a digital thread maximizes all the benefits of material intelligence, including its support of sustainability and compliance.

Database management platforms and tools naturally help facilitate a digital thread. These types of database solutions pool resources together and, in doing so, create an interconnected experience. Accordingly, with its database architecture and integration capabilities, Granta MI intrinsically supports digital thread creation as a materials information management system (MIMS). This is also true for simulation process and data management (SPDM) solutions such as Ansys Minerva and other product life cycle management (PLM) platforms, which provide data management for simulation workflows and product life cycles, respectively.

Intensifying its benefits, Granta MI’s materials data can easily be integrated with SPDM solutions to ensure that materials information is available at every stage of the simulation workflow. Additionally, both MIMS and SPDM offer an authoritative source of truth across other digital engineering solutions.

Other integration capabilities and advantages include:

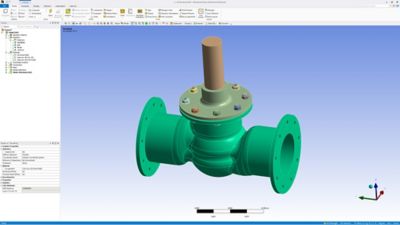

- Data exchange: Granta enables easy data exchange with various software tools, including CAD, CAE, SPDM, and PLM systems.

- Custom workflows: Granta can be configured to match specific workflows and business processes.

- API integration: Granta provides application programming interfaces (APIs) that allow for custom integrations with other software tools.

Integrate Granta MI with CAD, PLM, and other simulation solutions.

Support Sustainability

Material intelligence contributes significantly to operational sustainability internally and externally. Knowing the properties of materials and details about their carbon footprint, toxicity, and recyclability at the earliest stages of design empowers organizations to choose materials that align with corporate sustainability goals and reduce the environmental impact of their products.

The benefits of material intelligence for sustainability efforts are magnified when integrating this data into a digital thread. For example, by linking materials data with innovation processes, organizations can drive sustainability-focused research and development (R&D) efforts and manufacturing processes. Likewise, material intelligence integration with supply chain data ensures that suppliers adhere to sustainability standards and ethical sourcing practices. This transparency fosters responsible supplier relationships and encourages sustainable practices throughout the value chain.

Further, with traceability, organizations can access accurate information throughout all stages of development and better manage materials usage. This minimizes waste and reduces the consumption of natural resources, contributing to a more sustainable production process. Also, material intelligence supports life cycle assessments (LCAs), which evaluate a product’s environmental impact from raw material extraction to disposal. This enables organizations to identify areas for improvement and make eco-conscious design decisions that support the transition to a circular economy in which materials are recycled, reused, or composted.

Build Cleaner and Smarter

Material intelligence and the creation of a digital thread for materials enable organizations to make informed, sustainable decisions throughout the product life cycle. These eco-conscious approaches help reduce environmental impact, optimize resource use, enhance regulatory compliance, and align with broader sustainability objectives.

To learn more about the practical application of Ansys’ materials solution in the automotive world, register for the webinar Material Intelligence for Sustainable Automotive Design Webinar Series.