-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS BLOG

June 4, 2020

Harnessing the Power of Ansys EMA3D Cable

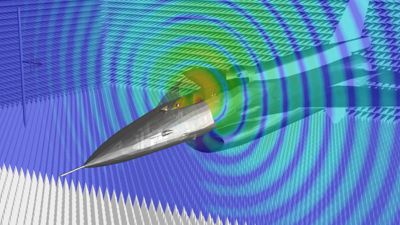

Designing cable harnesses for automotive and aerospace equipment is a daunting engineering challenge. This is primarily due to the difficulty in assessing the impact of electromagnetic (EM) effects induced by factors such as interference, crosstalk, insufficient shielding and lightning strikes. It is critical to mitigate these EM problems to meet stringent demands for electromagnetic interference/compatibility (EMI/EMC) certification of cable harnesses.

Widely used in automobiles, airplanes, ships and spacecraft, cable harnesses are crucial for transmitting electrical power and control signals to the electronics within these vehicles. Due to the size of these vehicles, cables are usually designed, installed and routed to extend over long distances to connect the electronic equipment. They must be protected from external EM sources such as high-intensity, radiated fields (HIRF) or a lightning strike.

Ansys EMA3D Cable, developed exclusively to design and accurately simulate EM effects in cable harness models, can overcome these problems. EMC tests of cable harnesses for large platforms are extremely expensive. With this new simulation tool, engineers can virtually predict the performance of their cable harness under these EMC certification tests economically and early in the design cycle.

Ansys EMA3D Cable — An Exclusive Cable Design and Simulation Tool

EMA3D Cable is the product from a partnership between ANSYS, Inc. and Electro Magnetic Applications, Inc. (EMA), a leading 3D simulation, consulting and measurement company. It is a robust platform-level EMI/EMC cable design and simulation solution. It helps engineers identify EMI/EMC problems in automotive and aerospace devices along with RF systems. EMA3D Cable’s accuracy enables cable simulations to be used as the basis for final acceptance or certification.

An EMA3D Cable simulation showing radiated emissions from cable

designs inside an airplane

It uses Ansys SpaceClaim’s Direct Modeler UI, known for its ease-of-use, to create and import geometries of arbitrary shapes and sizes. EMA3D Cable enables the user to quickly define the contents of the cable and simulate the model with just a few mouse clicks. This solution bolsters Ansys’ design-to-validation workflow to include cable certification support as well as system level EMI analysis for cable harness models.

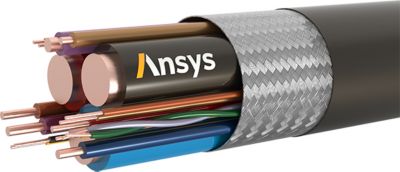

Typical wiring harness bundle with twisted conductors and braided shield

It is important to properly design and verify shielding and routing of electrical wiring system cables. EMA3D Cable enables engineers to investigate large platform designs and assess protection schemes for cables. In later program phases, the same simulation may support final equipment and cable certification. In e-mobility and vehicle design, a surprisingly underestimated fact is that cable harnesses are one of the most expensive and heaviest components. As drivetrains are getting electrified and relying on more and more sensors, vehicle manufacturers are looking to reduce weight by removing shielding, thus causing more EMI issues. Engineers involved in cable design can use EMA3D Cable to mitigate EMI/EMC issues, increase cable certification support and reduce costs.