-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

-

Ansysは、シミュレーションエンジニアリングソフトウェアを学生に無償で提供することで、未来を拓く学生たちの助けとなることを目指しています。

ANSYS ADVANTAGE MAGAZINE

January 2021

Composites Expand the Industrial 3D Printing Palette

By Ansys Advantage Staff

Nearly 40 years after a Japanese researcher named Hideo Kodama created a rudimentary 3D printer by running photopolymers through a rapid prototyping system, the worldwide market for 3D printing products and services is enormous — estimated to be between $40 billion and $51 billion.1 And there seems to be only blue skies ahead, with a compound annual growth rate of approximately 26%.2

Given the gee-whiz nature of 3D printing — it’s been used to construct everything from a human bladder (a project of Wake Forest University’s Institute for Regenerative Medicine) to a working watercraft (a 2.2-ton boat printed at the University of Maine’s Advanced Structures and Composites Center) — it’s tempting to think that every advance that could be made has been.

But, as demand has accelerated, the tasks assigned to 3D printers have become increasingly difficult, such as building parts that have challenging geometries. Customers are also asking for more complex printing materials, including fiber-reinforced resins that are stronger, more durable and more functional than the ordinary thermoset polymers the industry grew up with. That means there’s room for new printing technology that performs better, faster and more affordably.

To expand the capabilities of composite printing for industrial applications and allow customers to leverage materials that were once inconceivable, or at least impractical, the engineers at Fortify developed the FLUX ONE 3D printer.

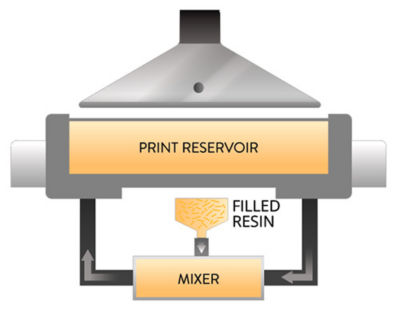

The FLUX ONE 3D printer automates the composite material build process by combining proven fiber reinforcement strategies with high-resolution digital light processing (DLP) printing. The printer’s features include continuous mixing of ceramic fibers and other functional additives that reinforce the photopolymer, and magnetic alignment of fiber strands for strength and stiffness.

Fortify engineers used Ansys Maxwell (part of the Ansys Electronics desktop), Ansys Fluent and Ansys Mechanical simulation software to streamline overall product design, reduce time to market, optimize the printer’s magnetic field, manage heat exchange and reduce power consumption.

Processes Improve Product Consistency and Strength

One of the areas Fortify is focusing on is industrial injection mold tooling. Whether the mold is intended for prototyping or low-volume production, the requirements for printing the tooling are the same: accuracy, high-detail resolution, industry-standard surface finishing and high-temperature resistance.

Traditional 3D printers often struggle to provide those must-haves. Functional additives can settle

to the bottom of the printer during the build process, causing unequal distribution from top to bottom and diminishing the quality of the tooling. In addition, getting the millions of microfibers aligned just right — a criterion for strength and durability during the injection process — has been difficult to achieve.

The FLUX ONE 3D printer overcomes both problems. Its patented Continuous Kinetic Mixing (CKM) process ensures consistent material properties with a broad range of composite material suspensions. The printer is also equipped with Fluxprint, an alignment module with multiple large magnetic coils; by coating the fibers with a magnetic material and then applying a magnetic field across the build area, the FLUX ONE 3D printer can selectively align the fibers to strengthen the piece, reduce the risk of wear or breakage in vulnerable areas, and improve thermal or electrical properties.

Continuous Kinetic Mixing (CKM) blends resin with additives.

Simulation Enables Magnetic Field Optimization

The challenge of creating a magnetic field that can be quickly tuned in any direction while optimizing magnetic flux density (that is, the magnitude of the magnetic field) is no easy feat, especially when engineers have to keep the printer’s power requirements and operating costs in check.

With Ansys Maxwell electromagnetic field simulation, Fortify engineers modeled a number of fundamentally different magnetic designs. By running simulations of the electromagnetic coils in tandem, the team could analyze the tolerance of the field direction in different areas of the build and determine how much power would be required to create each field.

Particularly useful was Maxwell’s probing tool, which enabled Fortify engineers to quickly and easily iterate designs, apply boundary conditions and run models at different currents and measure outcomes at different points of the build area. This simplified a complex problem to a few important output parameters, including the electrical efficiency of the magnetic field.

Maxwell simulations also helped them understand the relationship between the power required to generate the magnetic field and exchange heat through the fluid cooling system (which was designed in Fluent), and control the inductance of the magnet — that is, its tendency to oppose any change in the electric current running through it. Ultimately, this enabled Fortify to optimize magnet performance and response while removing heat and maintaining a reasonable power requirement.

Fortify used Ansys Mechanical as part of engineering due diligence as well, simulating the mechanical response to forces during the printing process.

By coating composite fibers in a magnetic material, the FLUX ONE 3D printer can selectively align the fibers to strengthen the part.

Printer Delivers Next-Generation Performance

Ultimately, Fortify engineers modeled dozens of design iterations before prototyping the FLUX ONE 3D printer. They would not have been able to arrive at the magnetic design without rapid iteration in finite element analysis; in other words, Ansys simulation enabled a solution that would not have been found otherwise, one that represents a previously unimaginable step change in 3D printing material performance for injection mold tooling and other applications.

Sources

- “3D Printing Market Worth $51.77 Billion at 25.8% CAGR,” Fortune Business Insights

- “Global 3D printing products and services market size from 2020 to 2024,” Statistica

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。