-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

The automotive industry is rapidly evolving, with increasing reliance on advanced electronics and software in vehicles. The enhanced functionalities demand greater computational power and add complexity to semiconductor designs. As a result, designers are challenged to ensure that the semiconductors driving these systems meet strict automotive safety standards.

Semiconductors play a critical role in the development of advanced autonomous vehicles, such as electric vehicles (EVs), and their security and connectivity. One of the key standards addressing these concerns is ISO 26262, which focuses on functional safety in automotive systems. ISO 26262 expanded to explicitly include semiconductor components in the scope of functional safety analysis for road vehicles.

The electronics essential in the development of advanced automotive can include:

- Image sensors/radars/lidars

- Vision processors

- Signal processors

- Artificial intelligence (AI)

- Connectivity solutions

- Hard-coded security features

The system-on-chips (SoCs) used in these safety-critical systems feature advanced multicore designs, offering high levels of integration, functionality, operating speeds, and power management. It’s common to see heterogeneous dies (2.5D/3D-IC configurations) to enhance performance and meet power efficiency requirements.

Chip designers can leverage simulation techniques to ensure that semiconductor intellectual properties (IPs), SoCs, and system-in-packages (SiPs) comply with the automotive electronics functional safety and reliability standards outlined in ISO 26262.

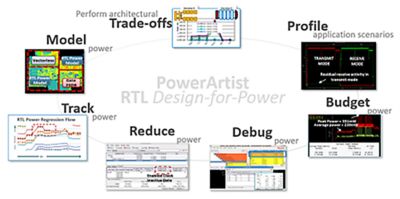

Ansys PowerArtist comprehensive register transfer level (RTL) power analysis and reduction software enables chip designers to improve the power efficiency of automotive ICs.

What Is ISO 26262?

ISO 26262 is an international standard for functional safety in road vehicles, providing guidelines for the entire life cycle of automotive systems and components. Originally published in 2011, the standard has undergone revisions, with the most recent edition released in 2018. It applies to all elements of a vehicle, including hardware, software, and human interactions, ensuring that safety is considered from concept through decommissioning.

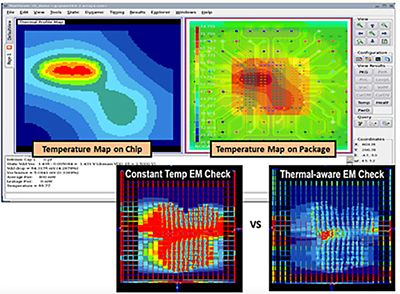

Example of thermal-aware electromigration analysis for filtering EM hotspots that need to be fixed

Why Is ISO 26262 Important for Semiconductors?

Semiconductors play a pivotal role in modern automotive systems, powering everything from engine control units (ECUs) to advanced driver-assistance systems (ADAS). As vehicles become more automated and interconnected, the need for robust safety measures in semiconductor design and production becomes paramount.

To achieve ISO 26262 certification, integrated circuits (ICs) must undergo rigorous functional safety testing and qualification. Each semiconductor component in a vehicle must meet safety requirements corresponding to various automotive grade levels. For example, a car operating in the sweltering heat of Las Vegas must be just as safe as one in the frigid winters of Canada. Therefore, all components must successfully pass electrostatic discharge (ESD) and thermal stress tests to ensure reliable operation under diverse conditions.

Given that cars typically last 10 to 15 years, chip designers must demonstrate that autonomous and ADA systems maintain a zero-failure rate throughout the vehicle's lifespan. To ensure these systems uphold functional safety over time, designers need to incorporate sufficient redundancies to address any potential failure modes. One of the most effective ways to guarantee semiconductor quality is by certifying automotive ICs to ISO 26262 standards.

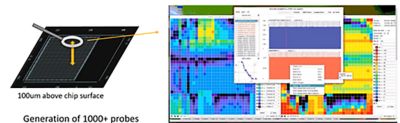

Electromagnetic (EM) side-channel assessment of cryptographic key disclosure

Simulation Challenges To Meet ISO 26262 Automotive IC Requirements

Simulating the semiconductor devices to enhance performance and reliability is vital for achieving the desired functional safety in vehicles.

The simulation challenges to ensure that FinFET designs and 2.5D/3D-IC advanced packaging technologies meet ISO 26262 standard are complex because they require the use of multiphysics simulations.

For instance, autonomous systems need to be power-efficient. Otherwise, the car’s battery drains quickly — affecting mileage. Power reduction techniques like clock and data gating can maximize power efficiency, particularly when addressed early in the design cycle.

However, certain power reduction techniques, like power gating, may not be viable for automotive systems. For example, the time it takes for the system to wake up from its power gated sleep-state can be catastrophic in collision avoidance scenarios.

Another multiphysics challenge relates to how power impacts the thermal signature of a chip. Thermal effects can lead to long-term reliability issues; therefore, lowering the supply’s voltage is beneficial because it reduces the overall power profile. However, this results in reduced headroom affecting the power supply’s noise and variability, ultimately impacting the timing of the chip.

Security is a significant concern in today’s automobiles. Hackers can exploit power supply noise, electromagnetic (EM) emissions and thermal profile from semiconductor chips to gain unauthorized access to vehicles. Therefore, chip designers must identify and analyze hardware side-channel vulnerabilities during the pre-silicon IC design phase to ensure vehicle safety.

The relationship between power, noise, and high-speed switching in signal lines is exacerbated by electromagnetic crosstalk. This can lead to functional failures, reduced mean time to failure, or reduced performance of the product.

Chip designers can use Ansys’ semiconductor portfolio to deal with all of these multiphysics challenges to meet the stringent safety and reliability of automotive electronics systems.

Ansys Semiconductor Portfolio Meets ISO 26262 Certification

To meet ISO 26262 standards, chip designers need electronic design automation (EDA) tools that are certified within the ISO 26262 “Tool Confidence Level 1” (TCL1) category.

This certification ensures that the tools will not introduce errors in the design that will compromise the functional safety of the overall system. As a result, chip designers can ensure the safety of their electronic systems by understanding the EDA tool, including:

- Usage models

- Interactions with downstream tools

- Potential malfunctions or erroneous reporting

- Error detection and prevention methods

The Ansys semiconductor portfolio for power efficiency, power integrity, and reliability has achieved ISO 26262 TCL1 certification. This certification enables automotive IC designers to meet rigorous safety requirements for ADAS and autonomous applications.

Automotive chip designers can use Ansys PowerArtist comprehensive register transfer level (RTL) power analysis and reduction software, the Ansys Totem power integrity signoff platform for analog and mixed-signal ICs, the Ansys Redhawk-SC Electrothermal thermal and multiphysics signoff platform for 3D-IC, and the Ansys RedHawk suite of multiphysics simulations for all ISO 26262 safety-related development projects at any automotive safety integrity level (ASIL).

Ansys offers extensive multiphysics simulations that accurately model power, thermal, structural, reliability, and electromagnetic effects across chips, packages, and systems, helping to identify various failure mechanisms. Chip manufacturers can leverage Ansys multiphysics simulations to ensure their semiconductors meet the rigorous functional safety requirements outlined in ISO 26262.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.