Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

“The Ansys Startup Program has given us access to the range of tools needed for comprehensive computational fluid dynamics and finite element analysis. By running simulations on the cloud, we can unlock the potential to learn new things quickly about the performance of our products for different applications. The resulting insights gained ahead of construction or installation of our wastewater management solutions are massively valuable to us as a startup and our customers across the industry."

— Sean Mulligan, Chief Executive Officer, VorTech Water Solutions

According to the United Nations Environment Programme (UNEP), wastewater is a growing health and environmental threat. Yet with the right infrastructure in place, it has the potential to become a significant source of reusable water and alternative energy.1 VorTech Water Solutions, an energy-efficient water and wastewater solutions specialist, has developed a groundbreaking platform of water treatment technologies based on vortex and cyclonic flows to solve water and wastewater challenges. The company envisions the global deployment of its products — including its advanced Vortex Power Aeration (VPA) technology — to enhance the sustainability and resilience of water and wastewater treatment infrastructure for future generations.

Challenges

Today approximately 80% of all industrial and municipal wastewater worldwide is released back into the environment without being treated or reused.2 Additionally, 20% of the world's population doesn't have enough water to sustain its needs.2 As populations and production continue to rise, the wastewater industry faces some immense challenges for the foreseeable future. One of the biggest challenges is connecting humanity to clean, potable water sources. All must be managed within the context of rapidly aging infrastructure and increasingly stringent treatment regulations designed to protect public health and the environment. Furthermore, global water use, treatment, storage, and distribution contribute to 10% of global greenhouse gas emissions,3 incentivizing the need for more sustainable industry solutions.

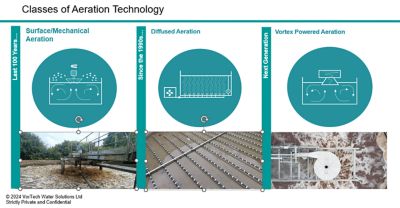

Figure 1. A visual comparison of the traditional aeration technologies and the new Vortex Powered Aeration (VPA) technology

Engineering Solutions

Thanks to the Ansys Startup Program and CADFEM UKI, an Ansys Elite Channel Partner, VorTech now has full access to multiphysics software coupled with high-performance computing (HPC) for comprehensive analysis of its water treatment technologies. CADFEM UKI coordinated access to Ansys licenses and on-demand HPC resources via CADFEM portal linked to AWS. This enabled VorTech to quickly adopt numerical methods for its processes and scale up simulations as required, specifically:

- VorTech used Ansys Fluent fluid simulation software for CFD analysis to understand the hydraulics taking place inside its VPA technology, then optimize and demonstrate mixing efficiency during wastewater treatment.

- Fluent-enabled CFD analysis was then coupled with FEA for fluid-structure interaction (FSI) analysis using Ansys Mechanical simulation software, which has become foundational to VorTech's structural design and technology development process.

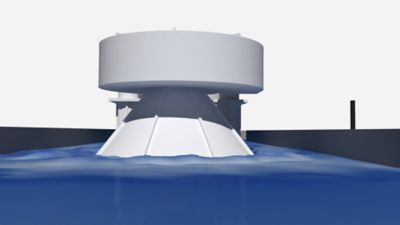

Figure 2. Surface flow around a VPA unit, as simulated in Ansys 2022 R1

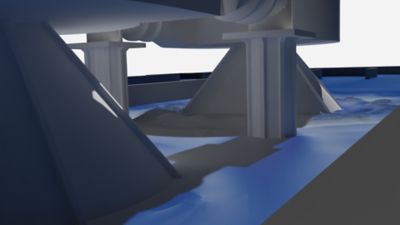

Figure 3. Surface flow simulated around multiple VPA units installed in oxidation ditches. Simulations conducted in Ansys 2022 R1.

Benefits

- Access to Ansys solvers at an affordable price point via the Ansys Startup Program enabled VorTech to design and develop an advanced aeration solution that is extremely simple, reliable, and efficient for a variety of wastewater treatment applications.

- Using Fluent and Mechanical enabled CFD/FEA-coupled analysis that resulted in a hydraulic vortex-based VPA technology with a single moving component for ease of maintenance and compatibility with same-day retrofits for existing infrastructure without downtime for the treatment plant required.

- Simulation facilitated VPA structural design optimization around built-in smart technology and control systems that can adapt to exact aeration requirements at any given moment in time, reducing energy consumption anywhere between 30-50% during aeration.

- From structural analysis of entire designs to virtual component-based simulation and testing, simulation has enabled VorTech engineers to scale back a several-cycle development approach to turn around a new, fully optimized unit in a single cycle, saving both time and costs.

- Quick access to compute requirements on the cloud is a scalable advantage in a startup environment prone to sudden growth spurts and stretches toward bigger offices, more equipment, and more personnel, with no real business impacts attributable to disconnection or downtime offline.

- Virtual piloting of new wastewater technology in a simulation environment for site-specific conditions has increased confidence within a risk-averse industry during the decision-making process, helping VorTech grow its business on a global scale.

Figure 4. A VPA unit operating in an oxidation ditch

Sources:

1. Down the Drain Lies a Promising Climate and Natural Solution — UN Report, unep.org, August 23, 2023.

2. ISO Sustainable Development Goals, Goal 6: Clean Water and Sanitation, Ensure Availability and Sustainable Management of Water and Sanitation for All, iso.org, March 15, 2023.

3. Greenhouse Gas Emissions in the Water Sector: Let's Uncover the Basics, waterrf.org, February 16, 2023.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。