-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

We’re likely all familiar with sci-fi movie scenes in which a character’s vision resembles the interface of a computer or phone screen. There are usually technical data readouts and options that the character can select by “clicking” on them with eye movements. XPANCEO, a Dubai-based deep technology company, is working to give us that ability through smart contact lenses.

XPANCEO’s goal is to merge all existing devices into one interface, enabling users to enjoy their most commonly used apps and software in infinite extended reality (XR). By projecting virtual images from the contact lens that the eye can comfortably see, wearers can have unlimited access to apps and data controlled by intuitive gaze commands.

There are currently no smart contacts or anything like them on the market. Mojo Vision, a micro-LED startup, created a prototype of something similar, but the company has since decided to focus on its micro-LED technology instead of smart contact lenses. Because this hasn’t been designed before — and direct placement on the surface of the eye is the goal — it is essential to calculate all the parameters accurately.

Now You See Me

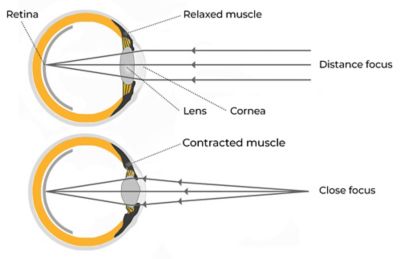

The average human can see roughly three miles in the distance and focus on objects as close as 2 inches in front of the eye. But as many people know, not everyone can see that far or that close with clarity.

How the eye focuses on far and near distances

This means that the projected images must be at a very specific distance from the eye to ensure a clear, comfortable experience. XPANCEO uses Ansys Zemax OpticStudio optical system design and analysis software, accessed through elite channel partner Fluid Codes, to simulate designs, reducing the need for physical experiments and prototypes and drastically lowering development costs.

XPANCEO engineers created a model with the same physical dimensions and structure as a real human eye, including the cornea, adjustable lens, aqueous humor, sclera, and retina. To replicate the eye more closely, engineers took advantage of OpticStudio software’s ability to set the detector screen in curved geometry and polar coordinates. Then they created a model of the contact lens that contained all the necessary components, such as the microdisplay, hologram, and gradient index lens. To keep the contact lens thin, the collimator integrated into the lens needs an extremely short focal length — less than 1 mm, ideally 0.1 mm to 0.2 mm. But in this geometry, light behaves differently at the intersection of geometric and wave optics, where diffraction, reflection, and scattering effects become significant.

Engineers placed the simulated contact lens on the simulated eye. By tracing the light paths, they observed the image on a detector screen emulating the retina. This enabled them to see how changes in the optical system’s parameters — such as its physical dimensions, its placement, its refractive index, and the number of elements — affected the retinal image. By working in nonsequential mode, XPANCEO engineers could easily add and remove optical components without disrupting the entire setup. The option to include and exclude some optical elements from calculations without deleting them from the file sped up modeling when toggling elements on and off and facilitated quick element changes.

“Simulation enables us to model and understand these complex optical behaviors without the need for physical prototypes, which can’t be tested before clinical trials,” says Dr. Valentyn Volkov, XPANCEO’s co-founder and CTO. “We use OpticStudio software because our engineers have extensive experience with it, it’s easy to use, and it’s reliable. Additionally, the robust support provided by the Ansys team ensured any technical issues were resolved promptly, maintaining project momentum and minimizing downtime.”

The integration capabilities of OpticStudio software enabled XPANCEO to import complex geometries from computer-aided design (CAD) systems that can’t be created in the OpticStudio software itself. “It was vital for us that the OpticStudio solution supports importing 3D models in formats like STEP and STL, facilitating seamless integration and ensuring accurate and comprehensive optical simulations,” says Volkov.

While trying to make a seemingly far-fetched idea a reality, simulation plays a key role for XPANCEO. It will use the simulation results in its optical laboratory for real-world optical experiments and measurements, which enables it to compare and align real experiments with its simulations.

Learn more about Fluid Codes and OpticStudio software.

Just for you. We have some additional resources you may enjoy.

“Simulation enables us to model and understand these complex optical behaviors without the need for physical prototypes, which can’t be tested before clinical trials.”

— Dr. Valentyn Volkov, co-founder and CTO, XPANCEO

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.