-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

The word “motor” brings automobiles to mind. But motors are found everywhere — anything that moves and is connected to an electrical source has at least one motor. That includes automobiles, airplanes, power tools, fitness equipment, home appliances (such as refrigerators, microwaves, blenders, and cooling fans), industrial equipment, pumps, and HVAC units.

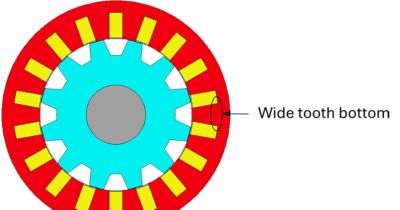

The ubiquity of motors means that there are thousands of engineers working on newer, more efficient designs every day for all varieties of motors, including brushless permanent magnet (BPM), induction, synch, outer rotor, and synchronous reluctance motors. The Ansys Motor-CAD dedicated electric motor design tool for multiphysics simulation often plays a large role in these efforts by offering engineers a simulation solution dedicated to motors that uses multiphysics technology to simultaneously handle the electromagnetic, thermal, and mechanical aspects of a motor design.

We’ve recently provided increased flexibility and the possibility to innovate with the Motor-CAD solution in our latest releases. The embedded Python-driven adaptive template capability is a major enhancement that makes these improvements possible.

The Advantages of Templates

Templates provide an easy starting point for an engineer looking to design a motor, avoiding the need to start each project from scratch. Templates often are used with a desire to modify them according to a very specific design. Customization is required to design a motor for an innovative application and gain an advantage over competitors.

The Motor-CAD solution has long offered templates for many types of motor designs, but until now customizing these designs has been more of a manual than an automated process. Engineers sometimes prepared a drawing exchange format (DXF) line drawing of a shape before importing it into the Motor-CAD software and running a simulation to see how it performed. The imported DXF didn’t have parameterized dimensions and couldn’t be used for parametrical studies, such as in sensitivity analysis\optimization. Limited scripting ability also made it possible to add parameterized nodes, lines, and arcs to the design, but more complex changes were difficult.

In short, motor design was largely a manual process. Making a change meant slow, manual repetition. Without automation, it was difficult to scale a design or explore geometric improvements for it. Also, you couldn’t reuse a customized design in different motors.

Adaptive templates have changed all that.

The Enhanced Capabilities of Adaptive Templates

The Motor-CAD solution's adaptive templates address these design problems. They give engineers more freedom with geometry creation and enable motor customization without the need for additional tools or expertise. Adaptive templates give you all the benefits of customization with the ease of use of built-in templates. Benefits of adaptive templates include:

- Automation of scalability in motor design, providing flexibility and ease of templated geometry.

- Full parameterization of the customized geometry with the capability to export the parameters to external optimization tools — that is, Ansys optiSLang process integration and design optimization software.

- Reuse of templates in any alternative motor design.

- Accelerated development of electric machines because you can build up your own library of templates comprising your own intellectual property (IP).

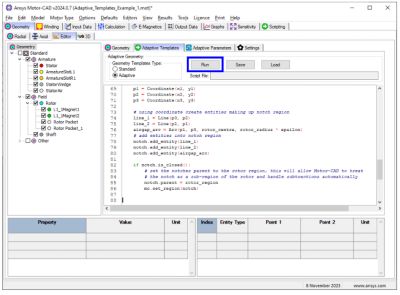

You can modify an adaptive template using built-in Python scripting capabilities in the Motor-CAD software. By changing model parameters using a Python script, you can create an adaptive template that you can save for future use, thereby accelerating the motor design process.

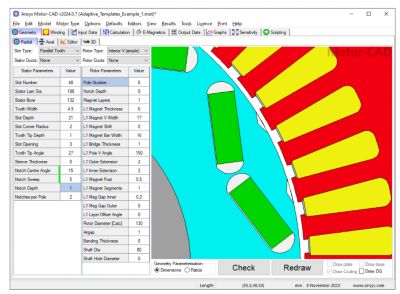

Example of Python editor with script to add notches on the rotor

In operation, it’s as simple as using the Editor function in the Motor-CAD software to view the motor’s geometry. Then, by clicking the Adaptive Template tab, you can insert a new Python script to change the parameters of the motor.

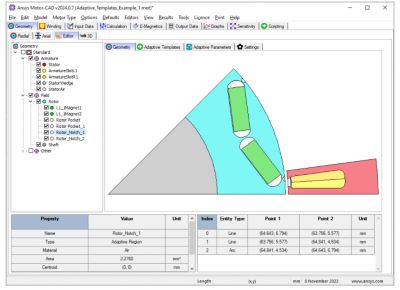

For instance, say you wanted to add triangle notches on the rotor of an interior permanent magnet synchronous motor (IPMSM) for cogging torque and torque ripple mitigation to in turn improve noise, vibration, and harshness (NVH). Adding some prewritten Python lines that contain these new parameters automatically changes the rotor design as specified. You can see the visual changes to the model in the normal radial view and verify that the new parameters — the angle of notch, sweep number per pole, depth, etc. — have been made in the parameters table. This adaptive template then can be saved for future use, in case additional modifications need to be made.

Addition of notches to the rotor of an interior permanent magnet synchronous motor (IPMSM) for torque and noise, vibration, and harshness (NVH) optimization using an Ansys Motor-CAD software adaptive template

Multiphysics Capabilities of Adaptive Templates

To make adaptive templates even more powerful in the Motor-CAD solution, we’ve ensured that they include the electromagnetic, mechanical, and thermal physics of motors for complete design fidelity.

Electromagnetics

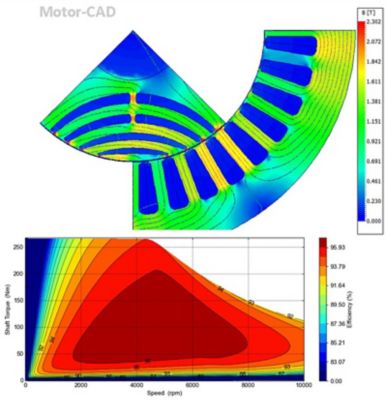

Electromagnetics is generally the starting point in most motor designs working off the base geometry. You can quickly perform a range of electromagnetic performance tests on prototype motor designs with Motor-CAD software, including calculation of torque, power, losses, voltages, currents, inductances, flux linkages, and forces. When we make changes using an adaptive template, the 2D finite element analysis (FEA) software solves that adaptive geometry directly, so it uses the real geometry, the same way you previously would use the DXF geometry import. But now it’s all automated — meshing, material, the winding setup, etc. AC winding loss due to eddy currents is also of particular interest in electric machines and cannot be neglected at high frequencies. Motor-CAD software has two options — Hybrid FEA and Full FEA — that are automated, so it’s easy to shift between the two.

Also, the Motor-CAD solution’s lab module for duty cycle calculations, efficiency map export for system modeling, NVH analysis, etc., is active for all adaptive templates.

Motor-CAD display for finite element analysis (FEA) flux density results (top) and efficiency map (bottom) for a synchronous reluctance motor (SYNCREL) with curved flux barriers

Mechanics

Mechanical simulation and analysis are important in two areas of motor performance: rotor stress analysis and NVH. If we set up a geometry in the electromagnetics module, it will be shared with the 2D FEA-based mechanical module, which solves rotor stress on the geometry directly with no additional setup required. Similarly, all the automation and workflows for NVH use adaptive templates as well. Going back to the IPMSM example with the rotor notches, the optimized electromagnetic forces acting at the stator frame are calculated according to the new adaptive geometry. The force data will be shared with the NVH module, which can effectively validate the NVH improvement.

Thermal

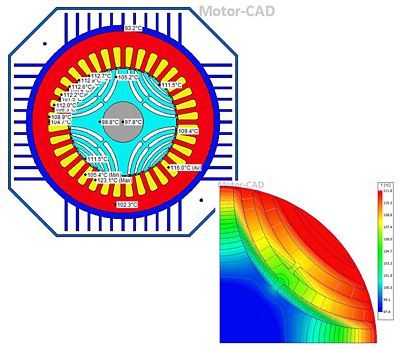

You also can calculate the temperature of motor components in steady state and transient operating conditions and accurately model thermal behavior in seconds. Adaptive templates work with the thermal module as well, as you can see in this image with an updated curved flux barrier and shape.

Updated thermal properties using adaptive templates in the thermal mode for a SYNCREL with curved flux barriers

In the thermal module, things like conduction are dominated by the interfaces between components, so it’s a bit less sensitive to small customizations. For major thermal customization, we still recommend customizing the thermal circuit. A key point to keep in mind here is that, when you make changes using an adaptive template, the cross-sectional area is recalculated for that new shape, so the calculations of masses and weights follow the new shape, and those parameters go into the thermal module for calculation of masses and capacitances, etc.

More To Come

We’re planning further enhancements to the Motor-CAD software adaptive templates in future releases. So make sure to check back to see what’s new with that release when it is available.

In the meantime, you can watch the Adaptive Geometry Templates in Ansys Motor-CAD webinar with demonstrations of how to use adaptive templates in the Motor-CAD solution.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.