ANSYS BLOG

January 29, 2019

Ansys has just released its first software of the year. With Ansys 2019 R1, engineers can expect to see workflow improvements that speed up product development and expand pervasive engineering simulation.

Ansys 2019 R1 empowers engineers to use simulation throughout the development cycle of any product in any industry.

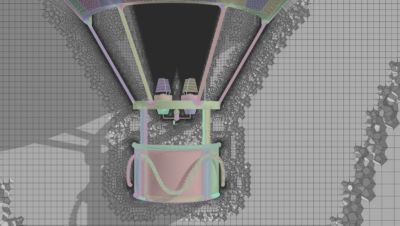

Ansys Fluent’s task-based workflows help engineers

quickly create

high-quality Mosaic meshes.

Continue reading to see highlights of the latest release.

Skip to Product and Industry-Specific Highlights for Ansys 2019 R1

- A new Ansys Fluent experience makes computational fluid dynamics (CFD) Intuitive.

- Ansys Mechanical nearly doubles its speed.

- Determine the optimal settings for metal additive manufacturing.

- Topology optimization added to Ansys Discovery Live.

- Simulation tools that ensure the reliability of electronics.

- New Ansys SCADE capabilities for the automotive sector.

- Functional safety analysis workflow for civil airborne systems.

- Ansys Twin Builder generates actionable insights for predictive maintenance.

- Optical simulation improvements focus on the automotive sector.

Ansys 2019 R1 will include a new product line — Ansys Motion.

MBD simulation shows how a car handles and swerves.

The new product line is a third-generation MBD solver offering a full suite of dynamics capabilities for rigid and flexible bodies. Ansys Motion also has an extensive range of application-based toolkits.

The creation of Ansys Motion stems from a decade of development in partnership with South Korea’s Virtual Motion.

To learn more about Ansys Motion, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

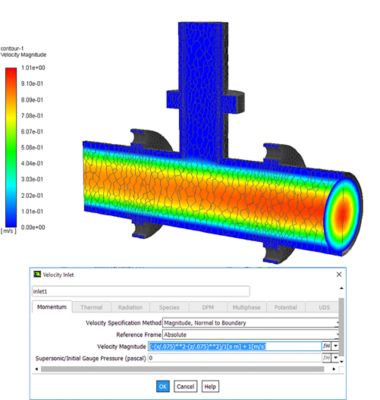

Ansys 2019 R1 introduces a new Ansys Fluent user experience. The intuitive workflow makes CFD more pervasive by enabling engineers to simulate more, in less time and with less training.

For instance, Fluent offers a single window that simplifies and speeds up the simulation process from start to finish. Ansys developers have streamlined the workflows for various tasks, including:

- Importing geometry.

- Meshing geometry.

- Defining boundary conditions.

Engineers can insert an equation directly into the boundary condition definition.

As an example, engineers can now input equations as boundary conditions without coding or creating a user-defined function (UDF).

Engineers can also try a beta version of a fault-tolerant task-based workflow. The workflow helps engineers mesh dirty, non-watertight geometries.

Other improvements to Fluent also aim to simplify or accelerate the simulation process, such as:

- The ability to generate a mesh seven times faster using parallel processing — without a high-performance computing (HPC) license.

- The generalized k-omega (GEKO) turbulence modeling that can be fine-tuned to specific simulations.

For more on Fluent, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

Ansys 2019 R1 includes improvements in the Ansys Mechanical suite that will accelerate product development.

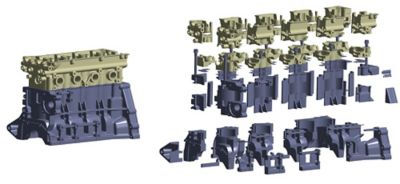

Ansys Mechanical’s new ability to split contact regions means that the finite element analysis (FEA) solver can scale more efficiently when solving assemblies.

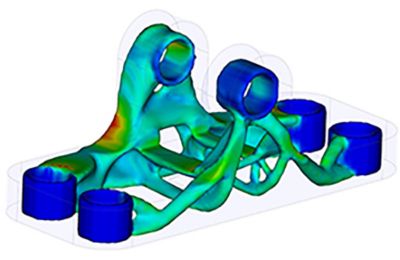

This engine assembly is split into regions to help distribute the computational load of the simulation.

Since the software can split contact regions, it can partition and distribute the computational load more evenly between compute cores.

So, how much can contact splitting speed up development? Tests show that a model with 9.1 million degrees of freedom (DOF) running on 256 cores can now be solved 85.8 times in a single workday. Without contact splitting, the same model could be solved 46.3 times.

The speed-accelerating improvements will benefit many engineers — even if they don’t have access to 256 cores. Richard Mitchell, lead product marketing manager at Ansys, says: “We can now make Ansys Mechanical run on 3,000 cores. To scale like this, every bit of code has to be as fast as possible. So, this way, all users benefit from a faster solver experience.”

Ansys 2019 R1 will have other Mechanical improvements, including:

- Topology optimization tools that lightweight shell geometry.

- Topology optimization tools that maximize heat transfer.

For more additions to Mechanical, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

Ansys 2019 R1 launches Ansys Additive Science, a new addition to Ansys Additive Suite.

The software tool helps engineers determine the optimal process parameters for a metal additive manufacturing machine.

For instance, engineers can perform parametric simulations to determine the dimensions of a printer’s meltpool or the porosity of a sample built by the printer.

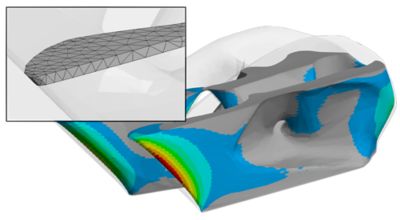

Layered tetrahedral meshing accurately captures the original geometry.

These simulations are based on a series of printer settings, including (but not limited to):

- Material selection.

- Baseplate temperature.

- Layer thickness.

Another improvement to Additive Suite is a new layered tetrahedral meshing option in Ansys Workbench Additive.

Layered tetrahedral meshing makes it easier to represent the geometry of a part without increasing the model size. This helps engineers represent the fine-featured geometry that additive manufactured parts are known for — such as narrow channels and thin walls.

For more additions to Additive Suite, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

The Ansys Discovery family of products continues to offer tools that are easy and lightning fast. These tools speed up product development and make simulation more pervasive.

This is best highlighted by the introduction of topology optimization in the Ansys 2019 R1 version of Ansys Discovery Live. With a few inputs, Discovery Live’s topology optimization tool can create a near-optimal, lightweight part.

A topology optimization in Ansys Discovery Live

Once Discovery Live creates the part, engineers can set up a simulation to learn — in real time — how to optimize it further.

Some beta features have also been added to Ansys Discovery SpaceClaim to speed up product development. These features make it easier to create and parameterize models, by:

- Controlling 3D models from the sketches used to create them.

- Updating models to sketch dimensions via the scripting menu.

Finally, Ansys Discovery AIM has expanded its physics capabilities with a new random vibration solution. This solution helps engineers determine the likelihood that a design will experience a certain displacement or stress when it’s exposed to a range of loads.

To learn more on Ansys Discovery tools, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

Trends like the internet of things (IoT), electrification and autonomous driving are pressuring engineers to add more electronics to every product. As a result, electronics reliability is more important than ever.

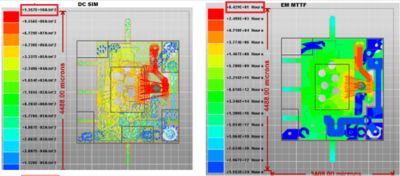

To address this need, Ansys 2019 R1 includes an electromigration analysis workflow for Ansys SIwave and an EMI Scanner for Ansys SIwave and Ansys HFSS.

EMI Scanner checks if a circuit board’s design follows engineering best practices.

The EMI Scanner takes a few seconds to ensure that a circuit board follows standard engineering design rules. This way, engineers don’t waste precious computational time simulating a circuit board that is bound to fail.

Additionally, the electromigration analysis workflow helps engineers determine the mean time to failure for chips and advanced electronics packages. Since electronics are becoming smaller, current densities are rising — increasing the risk of electromigration. Over time, electromigration makes copper wires brittle. The electromigration analysis tool ensures these wires will perform throughout the service life of the product.

Ansys 2019 R1 also includes electronics simulation improvements for the automotive sector, including:

- Noise, vibration and harshness (NVH) multiphysics workflow to develop quiet electronic motors in Ansys Workbench.

- Antenna blockage study to assess interactions between automotive radar and car bumpers in Ansys HFSS SBR+.

To learn more about electronics simulations, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

Ansys embedded software tools have a series of automotive improvements within Ansys 2019 R1. These improvements help engineers deliver safety-critical products with a faster time-to-certification.

For instance, Ansys SCADE now supports code generation for multicore chips, such as:

- Kalray’s Massively Parallel Processor Array (MPPA).

- Infineon's AURIX.

Ansys SCADE offers automotive improvements within

Ansys 2019 R1.

Ansys SCADE can generate target-independent parallel code from any legacy application.

Other industry improvements to Ansys SCADE, include:

- Faster and simpler AUTOSAR compliance workflows that develop model-based systems.

- A Test Model Coverage tool that checks for DO-178C and DO-331 errors.

To learn more about Ansys SCADE, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

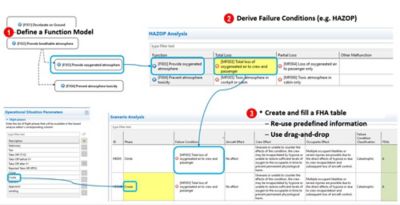

Functional safety engineers will notice product development improvements in Ansys 2019 R1. For instance, Ansys medini analyze provides engineers with a systematic workflow, in accordance with DO-178C, to assess:

- Aircraft system functions.

- Failure conditions.

- Safety requirements.

Ansys medini analyze provides engineers with a systematic workflow, in accordance to DO-178C.

The release also includes a new safety assessment process that is compliant with ARP4761 — Guidelines and Methods for Conducting the Safety Assessment Process on Civil Airborne Systems and Equipment.

Additionally, engineers will benefit from a new editor that calculates and visualizes function dependencies and allocation relations.

To learn more about medini analyze, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

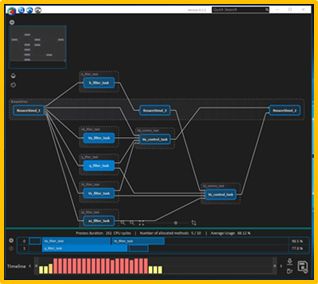

Ansys Twin Builder is a simulation solution that builds, validates and deploys digital twins.

Twin builder code controlling a digital twin

Twin Builder helps optimize a product’s performance while it is in operation. These performance improvements include:

- Root-cause analysis.

- Predictive maintenance.

- Control strategy analysis.

The latest release of Twin Builder supports runtime generation capabilities. These capabilities enable engineers to collect, process and interpret data from industrial internet of things (IIoT) platforms. These platforms include SAP Leonardo IoT, PTC ThingWorx and more.

Additionally, Ansys 2019 R1 introduces a dynamic reduced-order model (ROM) builder. The ROM builder is a machine learning tool that enables engineers to simplify and import complex dynamic models into Twin Builder. The simplification process preserves the features and accuracy of simulations while enhancing their speed.

In addition, Twin Builder incorporates IEEE VHDL-2008 encryption, which helps to protect intellectual property. The encryption allows engineer to encode, decode and exchange Twin Builder models without exposing their internal workings.

To learn more on Twin Builder, read: Next-Generation Pervasive Engineering Simulation — Ansys 2019 R1.

Or, skip to more product and industry-specific highlights in this Ansys 2019 R1 blog.

Ansys Speos has a few automotive- focused improvements in Ansys 2019 R1.

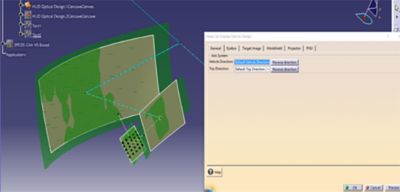

For example, the Speos head-up display (HUD) add-on helps engineers optimize the layout of an automotive dashboard.

The add-on is now compatible with Ansys Speos for Siemens NX. This compatibility enables engineers to optimize HUDs in a computer-aided design (CAD) environment.

The Ansys Speos HUD add-on

The Speos human vision simulation model has also been improved in Ansys 2019 R1. The new model takes pupil diameter and low luminance levels into account when forming an optical simulation.

The human vision simulation model helps automotive engineers optimize the look of a car’s interior and HUD with respect to the human eye.