Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

“Relying on Ansys Discovery for simulation has significantly enhanced our team’s ability to develop parts optimized for additive manufacturing, achieving unprecedented quality with remarkable efficiency. The rapid simulation times provided by Discovery have been particularly impressive, enabling us to iterate designs faster than ever. Furthermore, the post-processing capabilities within the Subdivision modeling environment have been exceptionally impressive, offering us a level of flexibility and precision in refining our results that truly exceeded expectations. This combination of short simulation times and advanced post-processing capabilities in subdivision modeling revolutionized our approach to developing optimized parts for additive manufacturing.”

— Markus Hofmann and Luis Atzenhofer, Mechanical Engineers, Running Snail Racing Team

Optimizing weight is paramount in the high-stakes world of race car performance, in which continuous improvement is not just a goal — it's a necessity. In this quest, topology optimization emerges as the most effective strategy for designing high-performance parts. By leveraging the cutting-edge capabilities of Ansys products, their design process was significantly accelerated. This has not only enhanced the team’s competitive edge, but also played a pivotal role in the outstanding performance of their latest race car.

Challenges

Previously, with conventional simulation software, a single simulation could take several days, leading to prolonged design cycles and limited flexibility for modifications. However, the team’s shift to Ansys Discovery has revolutionized the Running Snail Racing Team’s approach. Thanks to its innovative graphics card-based methodology, they can now conduct up to 20 simulations per day. This remarkable acceleration in the design process not only enhances efficiency, but also allows for greater adaptability and precision in engineering solutions.

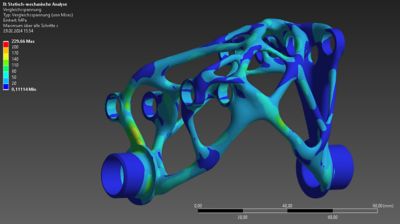

The von Mises stress in the part at cornering

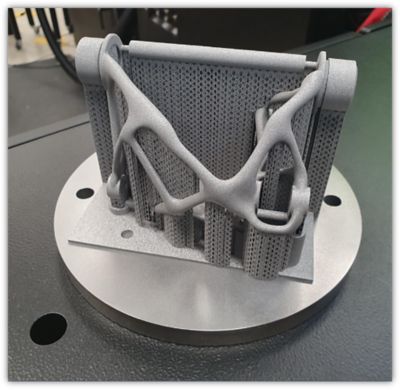

The titanium bellcrank from the team’s race car, the RS23, direct after printing with the milling and print support structures

Engineering Solutions

Using the Ansys Discovery topology optimization tool, the Running Snail Racing Team revolutionized their design and simulation process. The tool's rapid simulation times significantly enhanced their ability to adapt and iterate designs swiftly, which added immense value. Furthermore, Discovery's integrated features for converting facets into solids, either directly or through intermediate subdivision (SubD) modeling — while maintaining the integrity of exclusion regions — brought remarkable efficiency and precision to the development workflow.

Titanium bellcrank on the RS23

The Running Snail Racing Team at the Formula Student Czech event in 2023

Benefits

Discovery was essential for the development of the team’s topology-optimized bellcranks and uprights. This powerful tool enabled them to design bellcranks that are 40% lighter and 56% stiffer than their conventional milled counterparts. Moreover, the intuitive interface and rapid simulation times of Discovery cut the project's manpower requirements by half, freeing up valuable resources to drive further performance enhancements across their portfolio.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。