Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

“We really gained an advantage when using the cloud with Ansys Gateway powered by AWS. We wanted to run many scenarios at different power percentages, and our client was waiting for an answer within two days. These simulations take about 12 hours, so we had to deploy them on the cloud. We ran four simulations in parallel and were able to provide results within that period.”

— Marwan Charrouf, Lead Engineer, MPR Associates

MPR Associates is headquartered in the U.S. and is recognized internationally in the sectors of health and life sciences, power, and nuclear energy. MPR has contributed its skills and experience to solving problems related to fluid flow, including in power plant applications and for medical devices used in monitoring biological flows. MPR covers the full array of fluids in engineering and has assisted with federal projects. MPR uses an innovative approach and employs experts in validation and verification. For safety-related applications, they work with a high-quality assurance program in which they look at modeling predictions and compare them with physical test results to obtain comparisons and uncertainty quantifications.

Challenges

MPR Associates was asked by one of its customers in the nuclear industry to help address an issue with the power plant’s condenser. When in use, condensers cool exhaust steam from a turbine so that it drops below the boiling point and undergoes a phase change from gas to liquid. A condenser is sometimes used in short-term operation to also collect water from heater drains when a drain pump is not in service. When this pressurized condensate is exposed to condenser vacuum, it has more energy than it can contain at vacuum pressure. This excess energy converts a portion of the water into “flash” steam, which subsequently condenses inside the condenser.

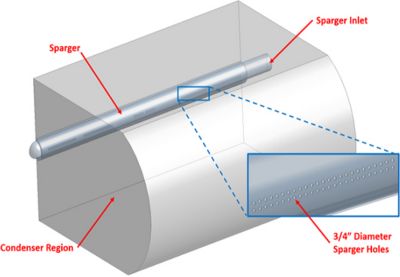

MPR’s client discovered some cracked welds on the supports of a sparger — a perforated pipe through which water flashes to steam — and its longer-than-normal use had damaged several tubes inside the condenser. These issues were found to be caused by high pressure, high-speed flow, vibration, and other steam-related physics. The client could not shut down the plant, but reducing the power generated was an option to reduce the fluid thermodynamic conditions going into the sparger, and thus the potential vibration. The customer needed to know which power level would be safe for the condenser, as power generation directly affects flow rate and velocity in the sparger.

The client’s condenser was several decades old and used a design that was not optimized by simulation. MPR was asked to quantify the limits of this critical asset.

MPR simulated the phenomena inside the condenser using computational fluid dynamics (CFD) to discover the maximum level of power in which to operate to prevent damage. It would have been impossible to stop the plant and do physical testing due to time and cost constraints, so simulation was used to find a solution.

Figure 1. Position and design of the sparger

Engineering Solutions

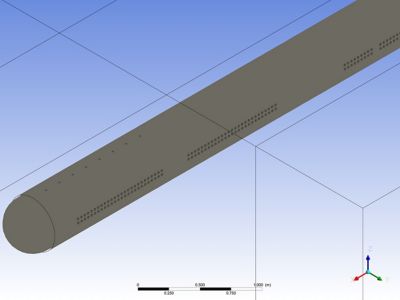

MPR developed the computer-aided design (CAD) model of the sparger using Ansys products.

Figure 2. Computer-aided design (CAD) files show modeling of the pipe, which was used to run the simulation.

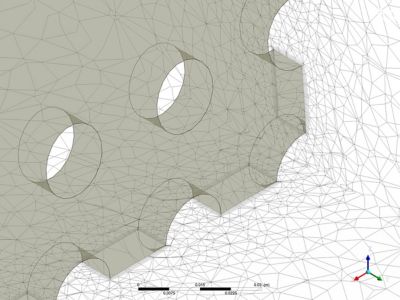

Figure 3. Mesh of the holes in the sparger

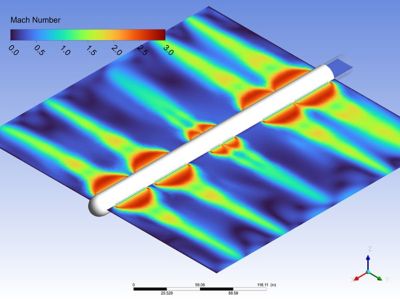

Simulation was particularly helpful in discovering that damage occurred due to shock waves. MPR analyzed the Mach number profiles calculated in the simulation, which indicates how fast the two-phase mixture inside the condenser is moving. (For example, a jet fighter exceeds Mach 1.5.) Analysis showed that shock waves were likely responsible for the damage caused by the flow on the condenser tubes when the plant was operating at 100% power.

Benefits

MPR was able to simulate multiple power level cases at 100%, 70%, 60%, and 45%. The results showed that reducing the power level drastically reduced the high-Mach zone and shrank the boom effect of the steam. The simulations were close enough to reality to even represent the polishing mark on the pipe made by the high-Mach jet. The shock waves also created a structure in the flow called a “shock diamond,” which was visible in the simulated flow field from Ansys CFX software. The more pressure added to the pipe, the more shock diamonds are produced, which leads to damage. The results of the simulations helped MPR give recommendations to its customer to reduce them.

MPR Associates was able to solve all simulations using the CPU-based instance Amazon EC2 c7a.32xlarge with 128 physical cores and 256 GB of memory. MPR has a similar cluster on-site powered by 128 cores and wanted to virtually reproduce this same configuration. Since the company is already using AWS (Amazon Web Services), it was a natural step for MPR to move in the direction of Ansys Gateway powered by AWS.

Figure 4. Simulation of the Mach number zone. High speed is shown in red around the muzzle holes.

For this project, MPR used 128 cores to run the simulation, given their model size. The model would have required use of the full capacity of the on-premises server, which was not possible given the number of employees using it. The bandwidth for “usual” projects at MPR is shared among a pool of engineers using 12-15 cores per project, but the cloud helped in this case, alleviating any bottlenecks in the workflow.

While MPR has not completed any benchmarks yet, it expects the cloud to be faster than using its server. The company notes that cloud technology enables access to the most recently released computer chips that offer the best performance. This hybrid approach of mixing server, on-premises, and cloud capabilities for peak demand enables MPR to be very competitive for urgent projects.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。