Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

“When you talk about customer requirements — autonomous function, machine learning, tracking — everything really depends on the quality of our radar data. This data is foundational to radar development. So, if the data is corrupted, things would go sideways. And that's why simulation is important. It helps us understand what's happening when a vehicle is sending out radio waves emanating from its radar, and how it's compiling all of the resulting data, so we can quickly identify and resolve issues that will ultimately inform future edge cases and optimize performance.”

— Yadhu Krishnan M K, Global Co-lead, Electromagnetic Simulation, Continental

For more than more than 25 years Continental has been developing pioneering technology and services in automotive domain, with a focus on advanced driver assistance systems (ADAS). This work includes radar sensors that are used for autonomous driving, including the integration of its short-range radars into various customer platforms. It involves careful consideration of the secondary surfaces and vehicle chassis components surrounding the radar that are critical to its functionality, as all can contribute to the losses and scattering of electromagnetic waves necessary to hit a target. From there, Continental must optimize radar applications through sensor placement or material application to prevent electromagnetic effects that lead to failure.

Challenges

Radar is an important aspect of autonomous function. By projecting electromagnetic waves out into the environment, it helps detect an object or objects in a vehicle's path. Specifically, when waves hit a target, some are absorbed as energy. Others bounce back to the vehicle, where that information is interpreted by a system of sensors responsible for detection, ranging, tracking, and sensing of nearby objects. This capability helps ADAS and self-driving technologies interpret a given driving scene.

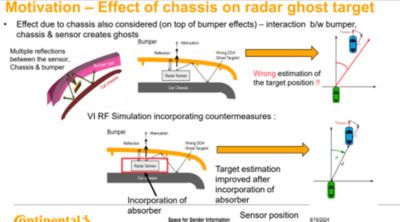

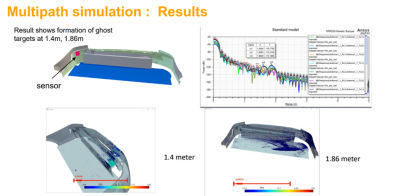

The path of the electromagnetic waves from a vehicle to an object can be affected by ghost targets, or areas inside the vehicle chassis that create multipath reflections along the way. Rather than leave the vehicle, some of these waves are reflected or bounce back off as input to the vehicle’s radar receiver, then incorrectly interpreted without ever reaching their intended target. In this instance, the corrupted waveform becomes the foundation for all subsequent signal processing, including machine learning and signal tracking that compromises autonomous function.

In assessing the front bumper area of a customer chassis, Continental was challenged to identify high-risk areas that cause these unwanted reflections, then optimize sensor placement or apply absorbing material, such as paint or fabric to help mitigate them. The engineers at Continental needed a practical and cost-effective way to pinpoint and understand these interactions to determine a precise mitigation strategy according to the path the electromagnetic wave takes.

“Radar integration is typically a complex environment in radar applications, as electromagnetic waves are prone to scattering due to reflections," says Yadhu "They’re the types of interactions that make a radio frequency engineer's life difficult. Electromagnetic simulation is a window into understanding complex effects due to multipart reflections on a sensor, as well as the crosstalk or electromagnetic interference happening between multiple sensors and electronics that interfere with vehicle perception."

Engineering Solutions

Input from a competing software suggested that the addition of crossbar or reinforcement structures to the vehicle environment surrounding the radar would be seamless. However, using Ansys HFSS shooting and bouncing rays (SBR) solver, the team discovered additional effects of ghost targets and the scattering of electromagnetic waves due to reflections only previously observable as measurements.

At the starting point of a design in which individual components are considered, Continental leveraged HFSS software to optimize sensor placement and reduce the amount of prototyping and measurement required. From there, the team used HFSS to consider the radar system as it would be integrated inside of a vehicle and evaluated its performance in relation to the fascia and complex chassis components in the vehicle.

Continental is also advancing its radar solutions with help from Ansys AVxcelerate Sensors software. Conducting analysis in this virtual test drive environment, it’s possible to assess radar performance subject to adverse weather conditions and other scenarios.

The team leverages a variety of computational resources to power Ansys simulations, including an on-premises single-node machine, and an on-premises HPC cluster on the cloud, allowing them to double their capacity when needed. As the complexity of their projects continues to grow, Continental anticipates scaling up cloud usage to meet these increasing demands."

Benefits

Ansys software enabled Continental to quickly identify and address wave scattering and ghosting issues of its short-range radar solutions in the context of individual customer applications throughout the validation journey.

Specifically:

- HFSS simulations led to a deeper understanding of the performance of the electromagnetic waves emanating from the radar and their deterioration in various scenarios, as well as impact of materials and sensor positioning within the chassis.

- Running HFSS software on the cloud scaled well, enabling engineers at Continental to run large simulations with greater accuracy and speed. Simulations were at least 18 times faster than the previous tool they were using.

- In decreasing overall simulation time, the team could complete projects much faster, thereby increasing productivity and finding efficiencies that resulted in a significant cost savings.

- Using AVxcelerate Sensors software, Continental extended radar functionality testing to virtual test drives in a realistic environment to understand vehicle perception as a function of additional effects.

- Ansys simulation helped identify the exact area inside the vehicle or root cause for the ghost targets, then determine the appropriate application of absorber material needed to eliminate unwanted signals.

- AVxcelerate Sensors can also import and preserve the radar sensor placement data from HFSS, then use it to successfully replicate the effects of electromagnetic scattering in a virtual driving scenario.

- Implementation of the Ansys toolchain for several hundred product lines across various projects will save automotive manufacturers in vehicle testing, while the toolchain itself can be further monetized as a simulation work product to help advance radar solutions.

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。