案例研究

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

「Ansys 軟體的建模準確度對於我們在首次開發中就成功打造天線至關重要。節省開發週期、寶貴時間與經費,對每個人來說都非常重要,對於像 Argo 這樣的小型創新公司更是如此。此外,對於讓 Argo 在有限預算下完成開發目標,並提供滿足客戶與合作夥伴需求的高品質天線解決方案,Ansys 的新創公司計畫發揮了關鍵作用。」

— Manolis Frantzeskakis,Argo Semiconductors SA 執行長

5G 的環境正不斷演進。隨著 5G-Advanced 網路開放新的頻段,天線必須能夠支援 6GHz 頻段,並與新推出的私人網路與獨立基站相容。Argo Semiconductors 開發出一款為 5G 時代設計的超薄型天線。然而,天線的厚度帶來了頻寬上的挑戰,而無線電元件的高度整合也可能對天線造成不利的熱效應。

挑戰

5G 網路需要大量的無線電設備與更大型的天線陣列,這可能會影響訊號完整性。此外,6GHz 以下頻段的 5G 天線需要具備 3D 結構元件,這會提高開發與部署的成本。一種具前景的解決方案是重新設計天線陣列,使其可由傳統的印刷電路板 (PCB) 工廠生產,並整合與最佳化天線陣列與分配器/結合器的設計流程,打造能協同運作的元件系統。

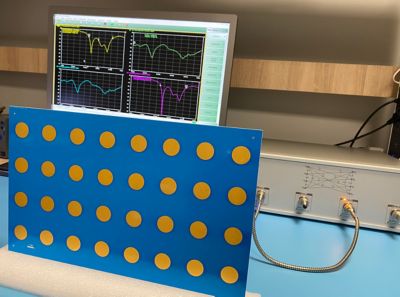

Argo Semiconductor 的 4x8x2 天線陣列

工程解決方案

- HFSS 在面對大型陣列時表現卓越。

- 透過 HFSS 進行了各種參數化研究與最佳化分析,以有效滿足穩健的設計規格,同時啟用 Ansys HPC 進行平行解決方案分配以實現可擴展性。

- 透過 HFSS,ArgoSemi 善用天線陣列結構的重複性,開發出整合式 2D 印刷天線。

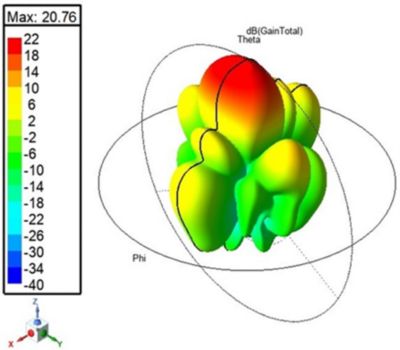

- 陣列設計被模擬為有限陣列,並在 S 參數與輻射方向圖中成功納入所有邊緣效應。

- 天線陣列與整合式多元素分配器/結合器或移相器的共同設計進行協同最佳化,並透過原型模擬及驗證,與全波模擬結果達成一致。

4x8 天線圖的輻射方向圖

效益

- Argo 估計,相較於其他競爭工具,它的開發時間縮短了約 30%。

- 這款 2D 印刷天線可透過一般 PCB 製程進行製造,無需為既有的 3D 天線結構使用客製化製程。

- HFSS 能涵蓋多種頻段的更廣頻率範圍。

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。