-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

PRESS RELEASE

DATE: 02/23/2021

Optimo Medical AG and Ansys Transform Eye Surgery to Better Treat Astigmatism

Collaboration uses Ansys simulations to help ophthalmologists optimize surgery prep for faster patient treatment

Key Highlights

- Optimo Medical AG and Ansys are collaborating to combine high-fidelity structural simulations with digital twin technology to efficiently develop patient-specific astigmatism surgery plans and significantly enhance patient vision

- The collaboration also facilitates in silico clinical trials of new eye products, enabling engineers to detect design flaws and slash development costs

PITTSBURGH, PA, Biel, Switzerland, February 23, 2021 – To perform patient-specific eye surgery planning, dramatically improve vision and treat astigmatism, Optimo Medical AG and Ansys (NASDAQ: ANSS) are incorporating high-fidelity structural simulations with cutting-edge digital twin technology into next-generation surgery preparation. Delivering a solution that powers surgical precision to maximize patient outcomes, the collaboration also drives in silico clinical trials of new eye products — significantly reducing development time and cost.

Providing care for 15 million low-cylinder astigmatism patients each year has traditionally forced ophthalmologists to plan eye surgeries with largely run-of-the-mill statistical models. This has often caused suboptimal incision placement and imperfections in patient vision correction, requiring multiple operations to solve issues. By integrating Ansys® Mechanical™ with Optimo Medical AG's Optimeyes™ digital twin technology, ophthalmologists are creating identical digital copies of patient corneas to test surgical strategies for individual patients that substantially improve results.

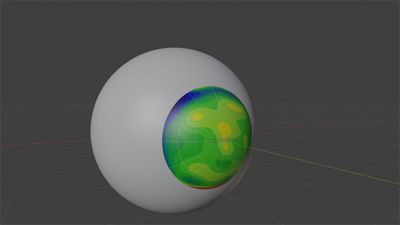

Optimeyes, embedded with Ansys Mechanical, reveals eye imprinter axial curvature

"Before I started using Optimeyes, like all ophthalmologists, I was forced to work with one-size-fits-all statistical models, which frequently lead to overcorrections. With Optimeyes, I'm now able to work on a patient-specific approach," said Dr. Johan Blanckaert, ophthalmologist at Oculus Clinic. "Since then, I deliver superior results, which means a spectacle-free life for my patients. Hence, I consider the usage of Optimeyes in surgery planning to be a real game changer within the industry."

Integrating Mechanical with Optimeyes empowers ophthalmologists to perform virtual keratotomy astigmatism surgeries for enhancing individual patients' incision parameters. Additionally, it equips surgeons with a state-of-the-art planning tool for addressing low-cylinder astigmatisms during cataract surgeries and predicting operation outcomes. Optimeyes also facilitates in silico clinical trials based on Mechanical — enabling engineers to simulate new products, identify design flaws and save millions of dollars in development costs."

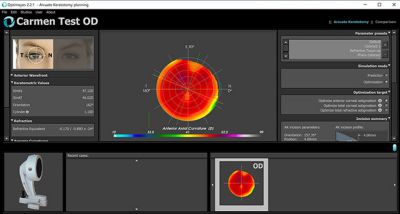

Optimeyes interface for ophthalmologists with Ansys Mechanical embedded

"In eye surgery, microns make the difference between a successful operation and disappointing results. Optimeyes uses Mechanical to guide eye surgery treatment planning, simulate the effects of physical interferences and enhance patient outcomes," said Harald Studer, CEO, Optimo Medical AG. "Together with Ansys, we are paving the way towards large-scale adoption of engineering simulation within the eye care industry and swiftly treating astigmatism for millions of patients worldwide."

"As the ophthalmology community exploits simulation to deliver personalized treatment, it is crucial to provide clinicians with simplified tools that speak their language," said Prith Banerjee, chief technology officer, Ansys. "Integrating Optimeyes with Mechanical delivers a next-gen solution for ophthalmologists to effectively battle cataracts and low-cylinder astigmatism. This enables first-time right surgeries, helping those suffering from vision impairment to regain a higher quality of life faster than ever."

Prith Banerjee, Ansys CTO, and Harald Studer, Optimo Medical CEO, join forces to bring simulation to clinicians

About Ansys

If you've ever seen a rocket launch, flown on an airplane, driven a car, used a computer, touched a mobile device, crossed a bridge or put on wearable technology, chances are you've used a product where Ansys software played a critical role in its creation. Ansys is the global leader in engineering simulation. Through our strategy of Pervasive Engineering Simulation, we help the world's most innovative companies deliver radically better products to their customers. By offering the best and broadest portfolio of engineering simulation software, we help them solve the most complex design challenges and create products limited only by imagination. Founded in 1970, Ansys is headquartered south of Pittsburgh, Pennsylvania, U.S.A. Visit www.ansys.com for more information.

Ansys and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

ANSS-T

查看 Ansys 的服務與產品

查看 Ansys 的服務與產品

立即聯絡我們

感謝您聯絡我們!

我們將在此解答您的問題,並期待與您交流互動。Ansys 的銷售團隊成員會立即與您聯絡。