-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

September 11, 2020

What is Reverse Engineering?

You might not believe it, but I’ve been to Jay Leno’s garage. It’s beautiful, classic cars as far as the eye can see.

One of the biggest problems that Mr. Leno and his motorhead cohorts face is needing a discontinued part. It’s a problem faced by many mechanics, and is not just confined to the automotive industry.

When a classic car breaks down, reverse engineering is often the only way to fix it.

Aircraft, industrial machinery, agricultural equipment, appliances and more can outlive their expected lifetimes, making parts hard to find. So how do you fix a machine when you can’t order the part?

The answer is reverse engineering. Reverse engineering is the action of recreating an existing design to replicate or replace parts that are impossible, or hard, to obtain any other way. It is generally used to fix legacy equipment or help engineers create designs to support third-party products.

The basic process is to replicate the part digitally — typically in computer-aided design (CAD) software. The digital geometry is created by hand or using scan-to-CAD technology. Once the geometry is recreated, the engineer can build the part using traditional or additive manufacturing methods.

Reverse Engineering Process

Reverse engineering is like being an archaeologist who discovers a part created by an unknown manufacturing process. They then study the part to understand how it works, how it was used and how it can be replicated. During a dig, an archaeologist might find an ancient machine. They can then reverse engineer parts of that machine, so it looks complete in a museum display.

Engineers using additive manufacturing to create a replica of a part.

In the engineering world, it works in a similar way. You may find a machine that is currently on the market or decades old. If the machine is broken and the original manufacturer is out of business, you may need to replicate a part to get it running again.

If you need to design a new part, but adjust the functionality of the original product throughout the new design, you will need to validate it.

Is Reverse Engineering Illegal?

The legality of reverse engineering is quite situational. Therefore, I suggest contacting a lawyer before recreating any product.

The general idea is to keep legacy equipment running when a supplier no longer exists. If you’re keeping your property in working order, then you are typically OK.

If you are planning on selling the parts, then that could get into some gray, or even black market, areas. Selling reverse-engineered parts could be likened to rebranding or mimicking an existing product — known counterfeiting techniques.

However, if you are recreating a part to build an add-on for customers of the original product, then you are probably OK. This would be like recreating a cell phone’s shell to design and test a product that mounts a phone to a car’s dashboard.

Legality tends to get complex when you need parts from a company that still exists but doesn’t support the product anymore. In situations like this, contacting a lawyer is a great idea.

How to Reverse Engineer a Part Using Scan-to-CAD Technology

The first step in a reverse engineering workflow is to accurately capture the dimensions of the part you’d like to recreate. This can painstakingly be done manually, but for many parts that is not practical. Thankfully, 3D scanners automate this work and are available at a number of price points. The 3D scanner will take measurements of the part as it forms a point cloud. You can think of a point cloud as a series of dots on a Cartesian plane. The scanner's software will then transfer the point cloud into an STL file.

An engineer scans a part so it can be recreated in CAD.

A 3D scanner can be as simple as a phone camera or as complex as a laser scanner on a robotic arm. The better the scanner, the more detailed the point cloud.

To transform the STL file into a watertight 3D model, engineers can use CAD software like Ansys SpaceClaim.

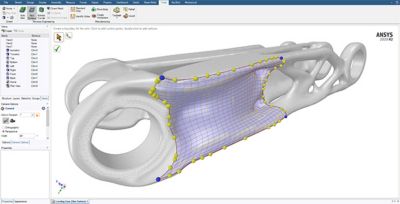

Ansys SpaceClaim can be used to transform a scan into a 3D model suitable for manufacturing.

Bad scan data is common in the engineering world, so it’s best to have access to tools that can accommodate incomplete information in the STL file. SpaceClaim has STL repair tools that can fill in patches, holes and missing faces. It can then blend these additions into the remaining geometry. This is useful for recreating a symmetrical part when you only have half of the original, or filling in the missing teeth of a gear, for example. If the original part is deformed, you can use SpaceClaim to digitally repair it back to its original shape. Get a free trial of SpaceClaim to check it out.

To find out more about scan-to-CAD technology, check out our 3D design webinar series.