-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS 部落格

February 12, 2024

邁入電動馬達設計的下一階段

從汽車產業到航空和工業應用,電動馬達如今備受矚目。但若要廣泛採用,電動馬達仍面臨許多挑戰,包括功率等級和可靠性。Optiphase Drive Systems 使用 Ansys 軟體推出創新的五相馬達設計,可推動變革。

在電動車 (EV) 馬達工程方面,三相設計是將電能轉化為機械能的業界標準。1889 年,德國 AEG 的 M. Dolivo-Dobrovolski 發明了三相馬達,依靠相同頻率的三個交流電來產生能夠驅動車輛的電磁相互作用。

三相馬達非常適合作為驅動 EV 的牽引馬達,輸出功率等級可高達 400 kW,馬達轉速高達 25,000 rpm,支援車軸速度高達 1,200 rpm。

雖然三相馬達的性能令人驚豔,但也有限制。舉例來說,它們缺乏航太與重型機械等新一代 EV 應用所需的轉矩與功率。錯誤容忍度也有限制;只要三個相位中有一個故障,馬達就會失去轉矩並停止。最後,最常見的 EV 牽引馬達解決方案是使用含有稀土金屬的高能量永久磁鐵,是永續性議題。

Daniel Vicario 和 Siavash Saidghi 創立 Optiphase Drive Systems (ODS) 來解決這些限制,並將 EV 的使用擴展至輕型車輛之外。這家位於德州的新創公司利用 Ansys 軟體,推出能革新產業的五相 EV 馬達設計,並且吸引投資人和政府機構的注意。Ansys 新創公司計畫協助他們努力將 EV 馬達變得更強大、更可靠且更永續。

搶先一睹 ODS 開發中的整合式系統,這個系統將公司的五相馬達與控制器結合在單一的精巧設計。

五相電動馬達:一個時機已至的理念

Vicario 和 Sadeghi 曾一起在燃氣渦輪機製造商 Capstone Turbine (現 Capstone Green Energy) 工作。他們在 2015 年離開公司時,基於對馬達設計和創業的共同熱情,決定與彼此保持聯絡。Vicario 轉職至 Parker Aerospace 和 Eaton,Saidghi 則任職於 Honeywell、Supernal 和 HyperLoop。多年來,他們保持密切聯絡。

ODS 執行長 Vicario 表示:「我知道 Sivash 正在完善五相電動馬達的設計,這是一個重要的理念,它有可能真正顛覆能源產業,並為社會帶來巨大的利益。」「我們只需要等待適當的時機。」

創新的馬達設計是由現任 ODS 的技術長 Sadeghi 開發,當時他正在喬治亞理工學院攻讀電動機設計和控制博士學位。他表示:「身為博士班學生,我針對五相馬達概念做了許多研究和原型設計,並在職涯起步時利用空閒時間繼續修正。」

Sodeghi 繼續說:「最後,我認為這項技術可以成功商業化。」「Daniel 和我知道這是全力追求的時候了。」

2017 年初,Vicario 和 Sadeghi 成立 ODS,專注於將這個想法轉變成商業化的專利產品。

推動車輛電子化的躍進

五相馬達的運作方式與三相馬達相同。然而,由於轉矩與來自相同馬達容積和電流的相位數成比例,因此轉矩會增加超過 15%。ODS 五相馬達提供多出 17% 的功率,速度範圍增加 6%,每次切換的電流負載減少 40%,而且不增加馬達的尺寸或重量,比三相馬達優異許多。這些規格可能使電動車馬達適用於全新的高功率應用範圍。

Sadeghi 指出:「這部馬達所提供的強大功率和轉矩將為各行各業和客戶開啟全新的生態系統。」「在航太、國防、航海、營建和農業等重磅重型車輛現在可以電氣化,不需要使用多個馬達來驅動。」Sadegi 開發的專有控制演算法,稱為 ADAPTIV,有助於將每次切換所需的電流降至最低,同時將功率密度最大化。如此一來,更輕巧的設計就能提供極高功率。

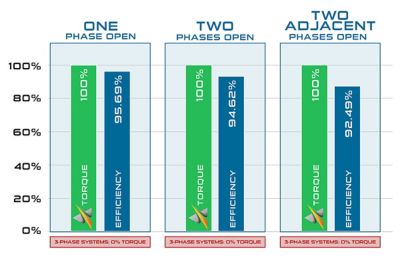

ODS 的五相馬達的容錯性也比現今的三相設計大很多。就算多達兩個相位故障,ODS 馬達仍能繼續產生轉矩。這代表比起三相設計,可靠性大幅提升。

Vicario 是前美國海軍軍官和飛行員,所以可靠性問題對他來說特別重要。他解釋:「我在空中執行美國海軍軍艦的遠程打擊和偵察任務時,我曾遇到因短路而造成設備故障,差點失去性命。」「這就是為什麼我對可靠的效能如此熱衷。不管是在偏遠地區行駛的家庭轎車、前往緊急現場的救護車,還是先進的航太應用,都無法容許 EV 馬達故障。我們的五相段設計大幅降低這種風險。」

環境衝擊也是電動馬達的關鍵。多虧 ODS 的五相技術與獨家設計,ODS 的 電動車馬達所需的稀土金屬較少。Vicario 與 Sadehi 表示,在以環保責任為前提建立的產業中,這是重要的優勢。相較於目前的三相電動車馬達,此系統預估還可降低 25% 的成本。

利用 Ansys 促進商業化

雖然 Vicario 與 Sadeghi 都不想透露太多資訊,但重型設備製造商、汽車製造商和美國政府機構已注意到五相馬達設計。例如,ODS 最近在其無人飛行系統 (UAS) 的發電挑戰中,向美國空軍展示其技術。ODS 提交提案並進入下一輪競賽,超越全球航太業界的幾位領導者,贏得此殊榮。

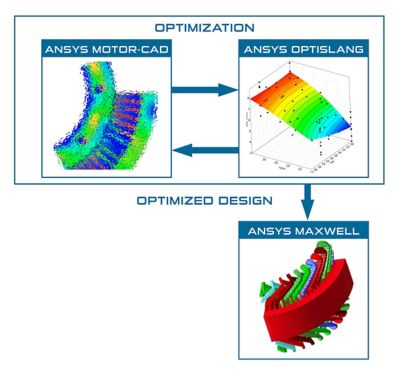

根據 Sadeghi 所說,在推動概念、驗證效能,以及向客戶和投資人展現潛力時,工程模擬至關重要。「2022 年底,我們與德州大學達拉斯分校合作,建造了實體原型馬達。沒有發生任何意外的情況,因為模擬已經預測設計會成功。雖然實際的概念驗證永遠是必要的,但模擬能為達成目標的過程節省大量時間與金錢。

Sadeghi 說:「要是沒有模擬,我們會需要花費數百萬美元來建置實體原型並反覆迭代,這對新創公司來說難如登天。」「Ansys 軟體使我們能夠反覆調整磁鐵等元件,不僅是為了在初期證明我們的概念,也是為了根據不同的客戶和產業應用調整基本設計。Ansys 的獨特之處在於,其工具組的範圍使我們能夠同時查看電磁和機械性能方面,並探索權衡取捨。」

Vicario 與 Sadehi 都很感謝能透過 Ansys 新創公司計畫取得 Ansys 軟體授權。Vicario 強調:「Ansys 讓我們取得領先業界的開發工具,的確是投資 ODS 等小型企業的未來。開始經營業務時,你不會擁有大筆現金流。Ansys 新創公司計畫提供的財務資源讓我們能持續投入這個產業。我們達到令人振奮的地位,而沒有 Ansys 就不會有如此成就。」

深入瞭解 Ansys 新創公司計畫。