-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

March 22, 2023

Keeping it Cool: Thermal Management Solutions for Electric Traction Motors

Designing an electric motor requires a deep understanding of the different technologies that can impact motor mass, performance, and cost — ideally at an early stage when design choices are still being considered and the cost of change is low. As electric machines become smaller, lighter, and more powerful, thermal constraints place significant limitations on how electric motors ultimately perform. The applications in the automotive market alone require effective thermal management systems, a multistage process to account for performance metrics, and the right materials to be viable in today’s market.

How to Choose the Right Cooling Method

Essentially, motor cooling ensures electrical components operate efficiently in electric vehicle (EV) traction motor systems. The main cooling methods used for EV traction motors are water jacket cooling and oil spray cooling. Of the two, water jacket cooling is considered one of the least complicated cooling methods. With this method, a built-in, water-filled casing wraps around the stator, or stationary part of the motor, and inlet and outlet connectors enable the water to circulate. Stator cooling is the result of standard heat exchange.

During the oil spray cooling process, heat is absorbed by oil sprayed on motor components that generate heat under high loads. Despite their varying complexity, either method can deliver powerful cooling, depending on the application.

To choose the proper cooling method, engineers must have a solid understanding of thermal performance needs given the size and type of motor they’re working with. Specific to EVs, vehicle performance is negatively impacted by high motor temperatures, and poor results in this area could prevent a vehicle from meeting quality and safety specifications. With an effective cooling system on a traction motor, engineers may have more freedom to take a simpler approach for overall vehicle cooling, which includes battery cooling, power electronics cooling, and the heating, ventilation, and air conditioning (HVAC) system.

For example, in a typical gas-powered vehicle, thermostats, coolant, and the radiator work together to remove heat from the combustion engine. In EVs, however, thermal management involves different responsibilities — cooling batteries, power electronics, and the traction motor. Because EV wheel movement is motor driven, the operating temperature of the electric traction motor is critical to the performance of the vehicle. When loads increase, the motor draws more power from the battery and heats up. This presents an increasingly complex matrix of engineering goals with thermal and electromagnetic coupling challenges at play.

To optimize system design, engineers are turning to simulation tools for accurate information that can support design changes and component selection at speed. Considering the traction motor alone, there are several design decisions that impact the function of the entire vehicle. This, in conjunction with the necessity of delivering increased power density and energy efficiency in a more compact form, puts thermal management at the center of more efficient electric motor designs.

Meet Electric Motor Thermal Design Challenges

Not all the energy provided by a charging station ends up being used to power the motor. Energy can be lost due to heat, friction, and other factors along the way. Managing heat improves mechanical efficiency, particularly in the face of increasing power density. The right cooling method can extend the life of the motor and improve lifetime efficiency by slowing insulation aging, keeping magnetic material below demagnetization temperature (in permanent-magnet machines), accommodating known limitations on power electronic components and lubricants, and limiting resistance.

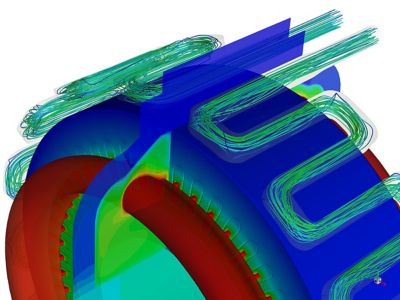

Ansys offers multiphysics simulation capabilities for all cooling types, helping to enable successful first-time electric motor design while considering the tight dependency of thermal and electromagnetic performance. Ansys Fluent and Ansys Maxwell are two of several tools that provide seamless bidirectional electromagnetic and thermal coupling with scalable computing needed to meet thermal challenges in electric motor design.

Ansys simulation and optimization technologies enable right-first-time design by considering the tight dependency of thermal and electromagnetic performance.

How to Select Materials

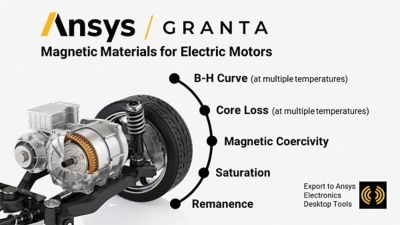

When faced with high temperatures, materials eventually exceed their normal operating range, causing phase change, softening, melting, degradation, and material fatigue. For example, some rare earth metals become demagnetized when they overheat, shortening the life of a motor. Engineers are faced with the challenge of balancing thermal management with the cost of modern, heat-resistant materials.

From selection to supply chain challenges, materials management plays an important role in the success of an electric motor design. Materials data for stator windings, thermal insulation, rotor shafts, and other critical components can be found in Ansys Granta MI. Ensuring that multiphysics simulation uses the most accurate material models for structural, thermal, and electromagnetic properties of the motor makes every difference in virtual prototyping.

Managing Heat Across the Electric Traction Motor Design Workflow

Ansys offers an integrated workflow for engineers to explore design requirements and trade-offs with an engineering workflow specifically created for electric motor designers. It supports engineers through early decisions, like motor sizing in Ansys Motor-CAD, through detailed electromagnetic, thermal, and mechanical analyses. The solution also includes Ansys optiSLang process integration and design optimization (PIDO) software and an integrated tool chain to seamlessly bridge software in the simulation platform. Ansys solutions help account for the tight dependency between thermal performance; noise, vibration, and harshness (NVH); and electromagnetic performance seen across EV subsystems.

Discover how Ansys thermal solutions for cooling system development enable faster, more reliable and efficient automotive electric traction machines. View the webinar: Cooling Strategies and Thermal Modeling for High Performance Electric Machines.