ANSYS BLOG

August 2, 2022

Targeting Cancer in a Flash with Simulation, Radio Frequency, and Electromagnetics

While every cancer case is individual, there is one shared truth: time is critical. We often hear how time is crucial in diagnosis or early detection, but it is just as imperative to treatment.

Engineers and radio frequency (RF) experts at medical technology manufacturer TibaRay are developing a groundbreaking radiation therapy (RT) system that will irradiate tumors 400 times faster than today’s conventional RT. As a result, the accelerated treatment is expected to solve problems that prevent curative treatments for individual patients and benefit a greater number of patients in the same amount of time as current methods.

As a member of the Ansys Startup Program, the California-based company is developing the next-generation RT technology by applying Ansys’ electromagnetic (EM) solvers and computational fluid dynamics (CFD) simulation software for faster, more accurate, and costefficient solutions. More importantly, TibaRay is employing simulation in the hopes of ultimately providing an essential contribution to curing cancer and bringing this treatment — which they describe as the “holy grail” of cancer therapy — to market before the end of the decade.

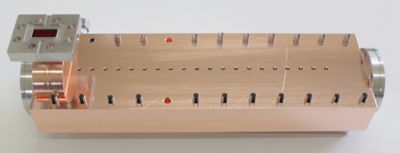

The PHASER has 16 accelerators that electronically target tumors with unprecedented speed for revolutionary radiation therapy treatment.

Pioneering Solutions with Ansys

TibaRay was founded in 2014 when a group of experts in radiation oncology, RF, and engineering with deep roots in the Stanford University community pooled their knowledge and resources to create a revolutionary solution for cancer treatment.

Dr. Bill Loo, a radiation oncologist at the Stanford Cancer Institute who has substantial experience using radiation to treat lung tumors, recognized a recurring issue between the breathing-induced movement of tumors and the challenge to deliver radiation more accurately, quickly, and efficiently without irradiating surrounding healthy tissue. He was searching for a solution when he reached out to Sami Tantawi, a microwave RF expert and electrical engineer from the SLAC National Accelerator Laboratory, a U.S. Department of Energy National Laboratory operated by Stanford University.

Tantawi and his team had just made a breakthrough discovery in developing stateof-the-art particle accelerators — machines that use EM fields to propel charged particles at very high speeds and energies through carefully formed beams — which far exceed the capabilities of existing technology. In other words, they were developing linear particle accelerators, also referred to as linacs, that could solve Loo’s primary challenge.

Loo and Tantawi immediately teamed to transform current RT systems by integrating the latest developments in particle physics with cancer treatment. To equip themselves with the latest simulation tools, the pair learned about the Ansys Startup Program through Ansys’ Elite Channel Partner, Ozen Engineering, Inc., and became a member in 2016. The program encourages early-stage startups by providing affordable access to Ansys’ simulation solutions coupled with technical support to help advance their businesses.

Today, TibaRay has roughly 15 full-time employees and a handful of part-timers who rely on Ansys’ simulation and predictive accuracy to develop a first-of-its-kind RT system they call the PHASER, an acronym for pluridirectional, high-energy, agile scanning electronic radiotherapy.

The PHASER combines linear accelerators with RF sources and components to create a nonlinear, fully electronic approach to radiation treatment that offers motion-freezing precision at record-breaking speeds from various angles to better destroy the tumor — without moving heavy mechanical parts around the patient.

“What we’re trying to do is a very heavy lift. It’s very intensive in terms of the design and the many components that we’re modeling with Ansys HFSS,” says Arun Ganguly, chief operating officer and chief technology officer at TibaRay. “It’s not a typical startup where it’s just a couple of years and then you have your product ready and one year or so of the Startup Program helps. We need the startup help for quite a bit of time, and the help we receive from the Ansys Startup Program is very much appreciated.”

In addition to HFSS 3D high-frequency EM simulation software, TibaRay uses Ansys Maxwell for low-frequency EM machine modeling, Ansys Fluent for CFD analyses, and Ansys Mechanical for stress analyses.

To understand the breadth of the PHASER, think of an octopus and multiply that by two. The PHASER is equipped with 16 accelerators — or limbs — that attack the tumor from different sides and angles. But since everything is electronic, there is no need to move any of the 16 parts.

But let’s back up. First, to power the PHASER, TibaRay designed an efficient klystron — a linear-beam electron vacuum tube — that uses periodic permanent magnet focusing and requires a much lower high-voltage power supply for operation than typical klystrons.

By pairing this high-efficiency klystron with RF combining technology, TibaRay engineers are able to generate peak power that can be scaled almost without limit. This creates more compact and efficient RF sources for the accelerators, which are fueled by the klystron source — the microwave generator.

Electrons are injected into the particle accelerators and interact with the microwaves to produce X-rays, which are then used in the radiation treatment. It is important to note that X-rays used for treatment purposes are at much higher radiation dosages than X-rays used for diagnostic imaging.

And because the PHASER is designed with simulation to operate electronically, the accelerators are not required to move. Instead, the microwave power is electronically toggled between each accelerator, which allows the team to shift the focus of the beam at unprecedented speed without any interference.

Radiation sessions that normally take several minutes — whether three, 10, or 20, depending on the treatment regimen — are reduced to under a second.

The PHASER operates electronically, using 16 different accelerators to target tumors from 16 different angles without having to move heavy equipment around the patient.

Electric Results with Simulation

Simulation is an integral part of operations at TibaRay, so much so that Ganguly refers to HFSS as the “bread and butter” of the PHASER’s design.

Each particle accelerator is injected with low-voltage electrons. In addition, each accelerator has a series of resonant cavities which are powered by the microwaves coming from the klystron. As the electrons pass through these cavities they interact with the microwave power inside them, gaining momentum and increasing in energy with each cavity. How much momentum? Within 2 feet, the electron power progresses from approximately 10,000 electron volts of energy to 10 mega electron volts of energy.

During this energy buildup, Ganguly and her team study where the resonant cavities are located along the path of the beam. This data, which comprises accurate and precise positions, is then entered into HFSS to determine the resonant frequency of each cavity, including the phase angle and field distribution within each, while stress analyses are performed in Ansys Mechanical. Based on these results, the team modifies and manipulates the cavity shapes to achieve the ideal direction for the charged energy and subsequent radiation.

Different devices are designed for varying resonant frequencies — the PHASER is equipped for an X-band frequency of 9.3 GHz. A few popular devices that operate at similar X-band frequencies include machines used in air traffic control, police radars, and military air traffic control.

By tweaking parameters in HFSS, TibaRay is able to design and influence the flow of the microwaves through the beam. The ultimate goal is for the microwaves to flow from the klystron source toward the accelerator, through the beam, without any power rolling or flowing back in the opposite direction, which could damage the klystron. HFSS also helped the team design a monitoring diagnostic tool to measure the beam itself.

While the EM simulation prowess of HFSS plays an integral role in the PHASER’s system design, Fluent allows the team to monitor and adjust thermal activity within the accelerator.

With such a high amount of power pumping through the beam, it is imperative to ensure that the temperature in the accelerator maintains thermal stability and that it is being cooled by circulating water. Thermal simulation also influences how the cavities are aligned during design to keep the most consistent flow in relation to its direction and temperature.

As the team sees HFSS as the bread and butter of the PHASER’s design, Ansys Maxwell could be considered its well-stocked pantry. TibaRay uses its low-frequency EM simulation to design the klystron — the PHASER’s main source of power — which requires a specific and strong magnetic field. With automatic adaptive meshing and advanced magnetic modeling, Maxwell enables the team to achieve the desired EM power within the klystron and understand its performance.

“There are other tools available to the highenergy physics world, but I would say Ansys’ simulation is the friendliest and most reasonably accurate way of being able to simulate all of our systems before going and cutting metal,” says Ganguly. “You visualize what you want to do before you actually go ahead and do it.”

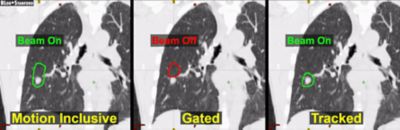

The PHASER produces radiation so rapidly that the treatment is finished before the tumor target moves, unlike current radiation therapy methods that must monitor breathing-induced tumor motion, as illustrated in the animation above, to deliver treatment while the tumor is in motion.

On-the-Mark Treatment in a Snap

A distinctive feature of the PHASER is its fully electronic operation, which removes the need for mechanical movement and significantly increases its precision and speed.

But a recent scientific discovery has increased the PHASER’s relevance even further. It is a common occurrence in conventional RT that surrounding healthy tissue inadvertently becomes damaged when targeting tumors. However, scientists recently identified a biological effect, commonly referred to as the “FLASH effect,” that eliminates this problem by delivering the same amount of radiation in much shorter times. FLASH targeting has demonstrated that surrounding healthy tissue touched by radiation recovers without scarring or damage, due to this surprising effect.

While this breakthrough came to light separately, Ganguly explains that it is essentially what the PHASER was already being designed to achieve. However, the FLASH effect is being studied in a totally different regime using protons, requiring machines and equipment with costs around $100 million.

Alternatively, and more advantageously, the PHASER uses electrons that produce highenergy X-rays, and its equipment costs run in line with traditional costs for RT machines, which are significantly more affordable at one-tenth of the price of a proton FLASH machine. Most importantly, it can deliver the same FLASH effect with the same motion management, speed, and precision.

The PHASER is also an all-in-one machine with a built-in CT scanner, whereas typical RT systems only have a flat panel detector capable of 2D projections. With a CT scanner integrated directly into the system, the PHASER produces real-time high-quality images during treatment for up-to-the-instant accuracy. Once the location of the tumor is identified with imaging, the treatment is finished before it moves.

High-Powered Perfection Takes Time

Developing the first engineering prototype of the PHASER takes time, but not as long as you might think.

As on-premises computing can only handle a certain amount of data and calculations, Ganguly plans to leverage Ansys’ cloud computing capability to expedite development. While the team will continue to determine individual parameters locally, Ganguly intends to optimize and accelerate larger, full-system calculations in the cloud.

At this rate, TibaRay expects to have the PHASER prototype completed in four years to request a 510(k) clearance from the FDA, which will allow it to be marketed as safe and effective for radiation therapy. Once this is secured, TibaRay will coordinate with leading radiation oncology centers to place PHASER machines on-site to treat patients in clinical trials and collect enough data to support the technology.