-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

July 8, 2022

Sprinting Toward Industrial Safety with Robust Relay Designs

According to the U.S. Bureau of Labor Statistics, more than 2.8 million work-related injuries and fatalities occurred annually. Of those, industrial accidents make up a significant part of this statistic.1 The prevalence of more advanced machine and automation technologies in industrial environments can make for extremely dangerous work conditions. Risk reduction is a top priority to protect people and reduce the possibility of costly accidents or equipment replacement. Machines must work every time, without restrictions to functional safety.

Phoenix Contact company headquarters

Phoenix Contact, a leading global component and systems manufacturer for industrial automation headquartered in Blomberg, Germany is using Ansys simulation software to build their safety relay switches to support more robust safety designs. The PSRmini is specifically optimized for use in machine building and the process industry, providing the much-needed space savings industrial environments require to manage the dramatic increase of signal, power, and data inputs used during production.

Maintaining safe industrial operations, regardless of application, requires a high level of risk mitigation. When it comes to heavy machinery on the shop floor, you can have a great safety design, but when you introduce human error into an industrial workflow, accidents are bound to happen. To offset the occasional machine operator mistake or equipment failure requires a fail-safe approach to system design. Many machines and robots rely on independent safety circuits housed in electrical cabinets to interrupt their operation in response to emergency events. These electrical circuits are typically part of a larger safety system and can interfere with a machine or robot’s operation when an operator is in close proximity to prevent injury on the shop floor.

Safety relays are a highly specialized, essential element in safety circuits common to industrial safety systems. In the event of a hazard, a safety relay will help reduce risks to an acceptable level. Each safety relay is dedicated to the monitoring of a specific function within a safety circuit. Connecting them together enables the total monitoring of a machine, a vehicle or a plant. Essentially, they monitor the safety circuits themselves, checking for those losses in safety function that lead to system faults related to wire breaks, faulty contactors, faulty safety actuators and timing — and are a simple, efficient asset to meet safety standards, resulting in safe equipment operation.

“Safety relays are to be found everywhere in the industrial segment, and especially in the machine building and process industries,” says Kay Willerich, director of Functional Safety at Phoenix Contact. “They’re used in a wide range of applications — basically anywhere you need to establish the safe state of a machine, including those related to energy infrastructure, like windmills. In the case of machine malfunction or human error, they act as a stop gap measure by regulating, or cutting off power to a motor to avoid catastrophic safety events.”

Scaling Down by 70% without Performance Trade-offs

To meet customer demands for affordability and scalability, machine builders are tasked with conserving control cabinet space without compromising overall system safety design integrity. Ansys simulation software enabled Phoenix Contact to simulate and build PSRmini safety relays, which they claim are the world’s narrowest. The relays offer the full performance of a large safety relay in a slimmer, more compact 6-millimeter design, enabling a space savings of up to 70% over more traditional relay designs.

Customer demands for the space-saving technology were high; however, because the sub-elements of the compact relay design were not available on the market at a smaller size, miniaturizing it would be a challenge. A critical core component in the safety relay — the elementary relay — did not exist under certain volume and size requirements, so Phoenix Contact decided to develop their own, smaller elementary relays based on these requirements. In this instance, typical design approaches for dimensioning would be ineffective, so the team turned to simulation technologies to solve their design challenges.

Predicting Safer System Outcomes with Reduced Order Modeling

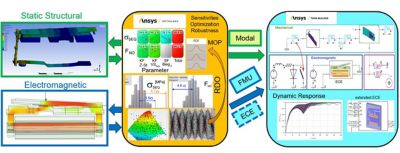

Phoenix Contact engineers took a cross-industry, innovative approach, applying lessons learned from the automotive market to design a more compact safety relay component. The team called upon the robust design optimization properties of Ansys optiSLang, plus Ansys Twin Builder and multiphysics capabilities to achieve their design objectives. The software was integral to understanding various complex systems involved, with a consideration of all of the real-world interactions related to the electromechanics, structural and thermal properties of the relay.

Using Ansys simulation solutions, Phoenix Contact was able to identify the materials, manufacturing processes, capabilities, and other environmental factors impacting production.

Twin Builder enabled reduced order modeling (ROM) to help Phoenix Contact engineers arrive at a full digital twin and help them understand the dynamics of their safety systems.

“We use Ansys Twin Builder as an integration platform to get the different physics — such as electromechanics, structural, and thermal — together with reduced order modeling (ROM) technology from Twin Builder,” says Christian Muller, senior specialist of development for Electromechanics at Phoenix Contact. “The goal is to check the dynamic response of the system quickly with the help of a system model. This enables the early detection of issues in relays like bouncing patterns and is an excellent approach to identify sensitivities of the overall system and get an overall system model.”

At times when the objectives of the engineering team at Phoenix Contact contradicted one another, optiSLang was used to help the team shift gears and uncover an alternative approach to design. By harnessing optiSlang’s robust design optimization, engineers could consider the nominal values as well as the distribution of the manufactured parameters of their more compact relay design. At the same time, they were able to identify the materials, manufacturing processes, capabilities, and other environmental factors impacting production. Basically, Ansys simulation enabled Phoenix Contact engineers to take all these parameters into account and achieve their goals for size at the same time.

Eliminating Physical Prototypes for Faster Results

Phoenix Contact offers PSRclassic and PSRmini safety relays that are able to conduct all safety functions including safety door, light grid or emergency stop, for usage with one function or one product.

If Phoenix Contact is the only player on the market to be able to offer such a small safety relay, it owes a lot to the use of simulation, according to the Phoenix Contact engineering team.

“This project was very technology-driven, and despite the challenges inherent in producing a unique relay design, our engineering team was able to develop the ideal component within an extremely tight time frame,” says Muller. “Without simulation, the entire design project would simply not have been possible.”

Simulation was an especially useful workaround for addressing issues linked to system hardware. By using simulation and certain state-of-the-art industry guidelines, the team was able to show that the smaller relays were not going to fail mechanically — something unachievable through actual hardware testing alone. According to Muller, the good thing about simulation is the ability it gives Phoenix Contact’s engineering team to apply multiple worst-case parameters to safety designs in a digital environment and see what happens.

“In reality, you can never produce enough prototypes with worst-case parameters,” says Muller. “Using simulation, we were able to prove that under certain circumstances, it's not possible to break any of the springs of the system while keeping within the safety margins defined in the FKM guidelines for computational strength verification of general machine components. Without this approach, we would never have been able to create so small a final relay without involving a lot of hardware.”

Thanks to Ansys simulation, the team could create many different design iterations quickly to replace the millions of physical prototypes that would have been required to thoroughly examine stress mechanics. In simulation, they could easily and instantly vary any parameter, like the thickness of a spring from one hundredth or two hundredths of a millimeter to see the direct impact on component stress. Alternatively, to create a physical prototype would require specific spring materials from the supplier, then physical testing amounting to 5-10 years of work to arrive at an optimal solution. Using Ansys software, team could run as many simulations as they needed to instantly look at the various aspects of testing outcomes — not just whether a particular result will pass or fail to meet design requirements, but also how it meets those requirements.

Phoenix Contact safety relays

Putting Durability to the Test With Ansys Simulation

During the relay design process, Phoenix Contact has extensively benefitted from Ansys’ simulation capabilities to assess electromagnetic and structural systems and plans to extend their efforts to durability testing in a near future.

“Durability tests are very complex and expensive to perform; however, simulating those will enable us to speed up the process even more,” says Muller. “Simulation will enable us to get to the exact values that will reduce the engineering time. The next step is to leverage Twin Builder for the creation of a functionality demonstrator thanks to digital twins to get valid feedback from our customers."