Sustainability has become a top priority for nearly every industry. According to the United Nations, fossil fuels contribute to over 75% of greenhouse gas (GHG) emissions and almost 90% of carbon dioxide (CO2) emissions. As such, many electrical manufacturers are developing more efficient products to contribute to the energy transition.

As a global leader in electrical products and services, the Sicame Group is dedicated to ensuring safe energy by advancing reliable, sustainable, and innovative solutions for transmission and distribution networks worldwide.

By integrating Ansys multiphysics simulation, the Sicame Group gains critical engineering insights that improve the electrothermal and mechanical behavior of its products. In addition, virtual testing and prototyping minimize the time and cost of traditional physical methods and accelerate product development, resulting in significant savings.

Optimize Electrical Engineering With Digital Tools

More than just a manufacturer, the Sicame Group considers itself a key player in the energy transition by designing, manufacturing, and selling electrical networks and accessories. The group specializes in products and services for electrical power transmission and distribution, renewable energies, electromobility, safety equipment, original equipment manufacturers (OEM), and commercial and industrial applications.

Incorporating a wide range of purposes, product examples include:

- crimped, screwed, and piercing electrical connectors

- electrical boxes, enclosures, and shelters

- damping systems for overhead lines (antivibration)

- wildlife and human life protection systems

- personal protective and safety equipment

- installation tools

- electrical connectors related to smart grids, Internet of Things (IoT) products, and printed circuit boards (PCB)

To optimize its engineering workflow, the Sicame Group started to integrate Ansys simulation about seven years ago. Today, the group applies Ansys multiphysics simulation to analyze a wide range of engineering dynamics, from structures and air flow to shock and vibration.

“The main objective (to integrate Ansys multiphysics simulation), when I proposed to my managers and top management, was to work out the same test, which is performed in our Cofrac laboratory,” says Guillaume Morin, digital simulation head at the Sicame Group. “These tests combine thermal, mechanical, and electrical behavior. Moreover, these physics are combined with each other. This is the main reason to improve our understanding of digital engineering to achieve this massive goal.”

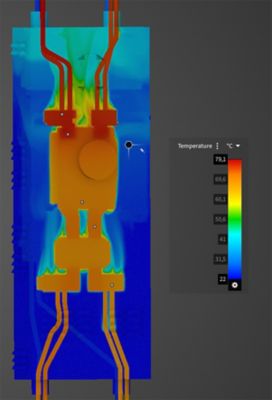

Fluid-thermal coupled analysis in Ansys Discovery 3D product simulation software

Cofrac laboratories are accredited by the French Accreditation Committee (Cofrac).

As a big proponent of multiphysics dynamics, Guillaume created the company’s first simulation division and works closely with the electrical networks research and development (R&D) department.

The main goal, he says, is to create a digital lab that can model the electrothermal behavior of a new electrical connection throughout its life cycle.

In addition, he hopes to leverage Ansys multiphysics’ simulation to study the electrostatic behavior of underground electrical accessories and safety equipment, including material selection, such as elastomer.

“The Sicame Group is offering its customers solutions for developing renewable energies, improving energy efficiency, and coping with climatic changes,” he adds.

Uncover Deeper Insight With Multiphysics Simulation

Guillaume and his team frequently use Ansys Mechanical structural finite element analysis (FEA) software to evaluate structures for product performance, especially different types of materials to understand durability. For example, they perform rheology and mechanical analyses to anticipate failures linked to the plastic material in transmission overhead accessories.

“Today, Ansys Mechanical software is used every day to analyze some structure,” says Guillaume.

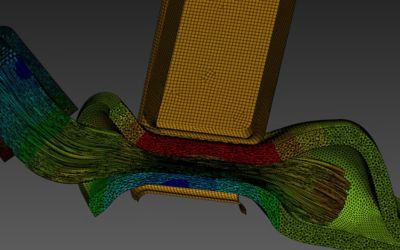

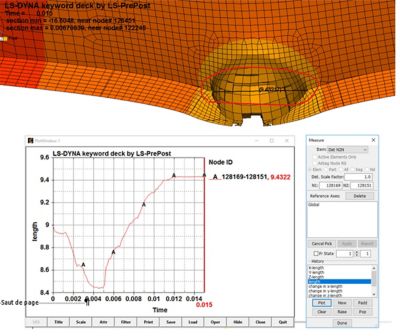

Crimping analysis in Ansys LS-DYNA nonlinear dynamics structural simulation software

The team also integrates Ansys Discovery 3D product simulation software for structural analyses as early as the design phase to assist in the dimensioning of mechanical products. But Guillaume says the software’s main use is to determine airflow inside electrical junction boxes and define the best locations for electrical accessories, including air inlets and outlets for natural convection. Discovery software is frequently used by Sicame Group subsidiaries, including Seifel and Hydel, which specialize in electrical boxes.

For shock, vibration, and crimping components, Guillaume and his team use Ansys LS-DYNA nonlinear dynamics structural simulation software.

Initially, the group developed expertise with explicit solvers by using Ansys Autodyn nonlinear dynamics software to conduct shock tests for electrical enclosures. However, wanting to expand their dynamics simulation use, Guillaume implemented LS-DYNA software into the workflow for shock and perforation testing.

Shock with material erosion in LS-DYNA software

“As we progressed, the superior performance of LS-DYNA software prompted us to increasingly dedicate it to crimping simulations, with the goal of validating the mechanical behavior of our crimped connections, including both power transmission connectors and lugs used in the automotive and aerospace industries,” he says. “Additionally, we are advancing a methodology for validating the perforation resistance of our connectors using LS-DYNA software, enabling the simulation of cables with a very high number of stranded wires.”

In electrical engineering, crimping is a method of joining wires or cables to each other to form an electrical connection.

Of course, electrical connections are at the heart of the Sicame Group. To determine and analyze the electrical fields of its products and accessories, the team relies on Ansys Maxwell advanced electromagnetic field solver. In addition, Guillaume plans to integrate Ansys Icepak electronics cooling simulation software and Ansys HFSS high-frequency electromagnetic simulation software to build a stronger digital lab and multiphysics workflow for electrothermal behavior.

Democratize Simulation and Increase Savings

Seeing the potential of simulation at the company, Guillaume wants to make the software more accessible for all team members.

“After several years of conducting simulations independently, the objective shifted towards democratizing simulation within the group and integrating it into the development workflow,” he says.

To achieve this, Guillaume and his team used Ansys high-performance computing (HPC) solutions to create an HPC architecture that would maximize the accessibility of simulation capabilities. This involved managing solver licenses and pre- and post-processing, as well as implementing remote server manager (RSM) and Windows™ HPC tools, which enabled Guillaume to internally manage the increased simulation capacity within his division. Currently, there are 20 employees using simulation.

“The initial architecture I developed quickly reached its limits, which is a positive indicator of the growing adoption of simulation within the group,” he says. “We are now in the process of completely overhauling our HPC system to accommodate this growth and address the various challenges we’ve encountered.”

To this end, Guillaume is exploring several options, including Ansys Access on Microsoft Azure cloud engineering solution, which would enable his team to better manage peak workloads, he says.

In the meantime, he credits Ansys for supporting the integration and empowering significant cost savings.

“At first, even before the benefits of simulation for the group, Ansys was able to support us in bringing simulation into the group, as well as providing the necessary assistance to develop the simulation activity,” he says. “For some applications, we have to work out many iterations that are impossible to test in the laboratory. But if we were to estimate the time and cost of these tests, apart from the fact that it’s impossible to monopolize testing resources for investigation, it would represent several months of testing and hundreds of thousands of euros.”

Guillaume emphasizes that simulation doesn’t just support short-term savings during development but enables long-term savings throughout production and by improving products using critical physics-based insight.

“Another valuable example is an electrostatic analysis, which allows us to design a new product with a potential gain of hundreds of thousands of euros for this new product versus the old one,” he says.

Sicame Explains the Benefits of Simulation

Guillaume Morin, digital simulation head at the Sicame Group, presents at the Ansys France Innovation Convention on Nov. 5.

Guillaume took the stage at the Ansys France Innovation Convention 2024 in Paris where he highlighted the Sicame Group’s methodology, development, and result of using LS-DYNA software for crimping simulations — the initial phase of an extensive project aimed at predicting the behavior of electrical connections from the early stages of development.

“Being able to anticipate the behavior of our connections before we even have a single part in hand, even a prototype, is crucial to our development workflow,” he says.

To explore LS-DYNA software, request the free on-demand webinar “An Introduction to Ansys LS-DYNA.”

Just for you. We have some additional resources you may enjoy.

“For some applications, we have to work out many iterations that are impossible to test in the laboratory. But if we were to estimate the time and cost of these tests, apart from the fact that it’s impossible to monopolize testing resources for investigation, it would represent several months of testing and hundreds of thousands of euros.”

— Guillaume Morin, digital simulation head, Sicame Group