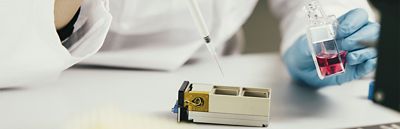

Space might not seem like the ideal place to grow much of anything, but microgravity has proven to be a suitable petri dish for many kinds of science experiments. From cancer growth and vaccine research to stem cells and tissue engineering, microgravity enables cells to grow in a way that we have a hard time replicating on Earth: three-dimensionally. Traditionally, cell cultures are grown in flat dishes. But we are not 2D, and neither are the tissues and cells that make up our bodies. Experiments conducted by NASA on past spaceflight missions have shown that cells grown in microgravity arrange themselves three-dimensionally, more closely representing in vivo biology.

Cells under a microscope in normal gravity (left) versus cells under a microscope in microgravity (right)

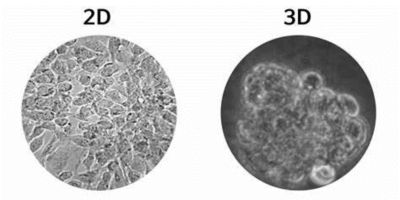

Yuri is a space biotech company that uses space’s microgravity environment to develop and manufacture biotech products. The company develops modular bioreactors and incubators for cell cultures, protein crystals, and plants and launches them to the International Space Station (ISS) and other spacecraft. Since 2022, Yuri has developed its own pipeline of biotech products that are either triggered by or manufactured in microgravity. This involves identifying novel space bacteria strains specifically for biomanufacturing, as well as triggering natural adaptation in the space environment to generate non-GMO microbes with adjusted characteristics.

Yuri was founded in 2019 by former Airbus engineers Maria Birlem and Christian Bruderrek, alongside serial entrepreneur Mark Kugel. Birlem and Bruderrek worked on countless ISS payloads during their time at Airbus and saw the huge potential of microgravity for the life sciences beyond government-funded research. Since then, the team has grown to more than 30 members between the headquarters in southern Germany and engineering hub in Luxembourg. The team of aerospace engineers and biologists has combined several decades of human spaceflight engineering and space biology experience to create a bright future for human health on Earth and beyond.

Yuri was contracted by the German Space Agency at DLR to put two payloads with experiments by the Hochschule Bonn-Rhein-Sieg University of Applied Sciences aboard The Exploration Co.’s Nyx as part of Mission Possible. Yuri is using simulation, with the help of Ansys Apex Channel Partner CADFEM, to make it happen.

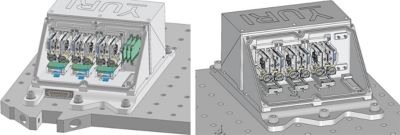

The hardware for the payload consists of two ScienceBoxes, an interface plate, and a plug integrated into the plate.

Your Package Has Been Shipped!

At the end of 2023, the European Space Agency (ESA) launched a competition to facilitate a cargo delivery service to and from space stations in low Earth orbit (LEO) by 2028. Today, Europe uses a bartering system with its international partners to bring cargoes and crews to space. However, with commercial companies catapulting the next wave of the space race around the world, there is an expectation that privately owned space stations, rather than institutionally owned ones like the ISS, will be developed. Instead of buying a ticket to get into space, Europe wants to develop its own way to bring cargo to and from space stations in LEO.

In May 2024, the ESA announced that it awarded two contracts for its commercial cargo program, one of which went to The Exploration Co. The company is developing a modular, reusable, and in-orbit refillable spacecraft called Nyx, named after the ancient Greek goddess of the creation of the cosmos.

The initial iteration of Nyx can carry up to 4,000 kilograms into LEO for up to six months. Currently, The Exploration Co. is taking prebooking applications from companies with all kinds of proposed experiments, including those concerning microgravity.

In addition to many other research projects that the DLR is involved with, this specific experiment focuses on spore germination in space radiation. As previously mentioned, microgravity is hard to replicate on Earth. Plus, recreating on the ground the amount of radiation that is in space could be hazardous to scientists’ health.

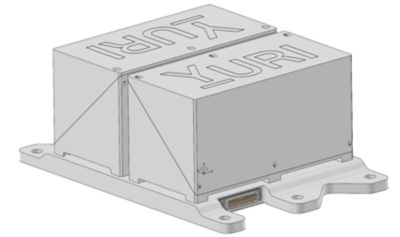

The spore samples being sent into space are a mold called Aspergillus carbonarius. While this might sound like the catalyst to a space version of the post-apocalyptic TV show “The Last of Us,” A. carbonarius is the primary culprit for grape rot. A. carbonarius spreads quickly, making it a good subject for science experiments.

Incubation of Aspergillus carbonarius at 30 degrees Celsius on a baseplate for 23.5 hours

Simulating Heat Tolerances

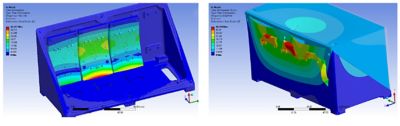

Yuri’s payload abord the Nyx will consist of two ScienceBoxes, a mechanical Nyx-adapter interface plate, and an electrical Nyx-adapter plug that is integrated into the interface plate. The company used Ansys Mechanical structural finite element analysis (FEA) software for the structural analysis of the payload interface plate and ScienceBoxes to identify nominal loads and areas for improvement.

The structural analysis performed in Ansys Mechanical structural finite element analysis (FEA) software (right)

Each ScienceBox contains three fluidic systems. Each fluidic system contains two membrane tanks, peristaltic pumps, a baseplate, and a culture chamber. Yuri develops these systems and 3D-prints them based on customer needs. The fluidic systems needed to meet specific scientific requirements for the experiment, such as:

- Activation of dried spores in microgravity by contact with a passive medium

- Gas exchange to supply the spores during the experiment

- Creation of microscopic images in microgravity

- Fixation of the spores at the end of the microgravity duration

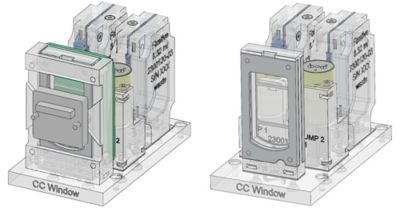

To capture the microscopic images, the primary ScienceBox contains lensless microscopes in each fluidic system while the secondary ScienceBox systems have no microscopes.

The primary ScienceBox (left) has three experiment units that each contain a microscope while the secondary ScienceBox (right) has three experiment units without microscopes.

Yuri added a camera sensor and micro-LED array next to the culture chamber to gather the microscopic images. The camera is a primary power consumer and therefore a primary heat producer. To get the needed images, the camera must sit close to the biological sample, which is always temperature-sensitive.

“The problem is, we have to stick the most temperature-sensitive component next to one of the largest heat-producing components,” says Daniel Kaschubek, chief technology officer at Yuri. He has been with the company since 2021 and led the development of the lensless microscope.

An experiment unit with a microscope (left) and an experiment unit without a microscope (right)

The distance between the spore sample and the camera sensor is only 1.3 millimeters. A temperature analysis of the spores determined that the temperature should not exceed 37 degrees Celsius or drop below 20 degrees C or else the spores won’t germinate.

“The Nyx capsule is a reentry demonstrator capsule, so its thermal system isn’t quite as optimized for payloads,” explains Kaschubek. “The temperature range we received from The Exploration Co. was between 0 degrees C and 50 degrees C, which is a much larger range than the spores will allow.”

And that doesn’t include the heat generated from the cameras. Unfortunately, due to the limited power of the payload, adding a cooling system isn’t possible. However, small heating systems can be added.

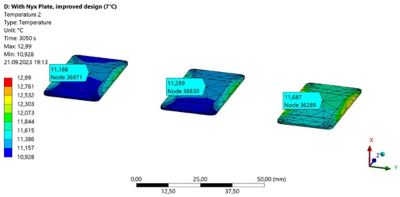

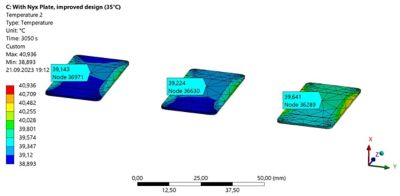

To determine the different temperature ranges with and without heating assistance, Yuri ran two thermal analyses using Ansys Fluent fluid simulation software — one in which the company assumed that the temperature would be 35 degrees C and another with an assumed temperature of 7 degrees C.

Thermal analysis of the cold case in Ansys Fluent fluid simulation software

Thermal analysis of the hot case in Fluent software

Based on these design cases, the company derived heating systems in addition to the camera that simply glues onto the culture chamber.

“The microscopes and thermal analyses are very closely related,” says Kaschubek. “The simulations help us to quickly and efficiently iterate our designs to meet all requirements. They also help us to perform trade-offs and check limitations. For example, we used the thermal analysis to derive maximum times that the microscope camera sensor can be operated, which then also drove further design decisions related to the microscope.”

The feasibility and user-friendliness of Fluent software made it easy for Yuri to quickly generate and analyze design cases. “The meshing is quite straightforward, and overall it is a very good integrated solution that allows us to cover multiple different analysis needs,” says Kaschubek.

While Yuri has come a long way with its designs, there is still work to be done. Since the Nyx capsule isn’t traditionally designed for payloads, Yuri has to send its completed ScienceBoxes to The Exploration Co. so the capsule can be built around the payload. Mission Possible is currently scheduled for 2025.

Learn more about Ansys’ structural FEA capabilities by visiting the Mechanical software page. To explore ways in which Fluent software can help you, click here.

Just for you. We have some additional resources you may enjoy.

"The simulations help us to quickly and efficiently iterate our designs to meet all requirements."

— Daniel Kaschubek, chief technology officer, Yuri