-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

January 9, 2020

How to Apply Rocky DEM to Generate More Accurate Structural Analysis

Imagine that you’re designing a bucket conveyor. How would you approach such a project?

Historically, engineers started with a known design, ran hand calculations, made assumptions and performed field tests. These designs likely failed their first trial. So, the engineers iterated and tried again.

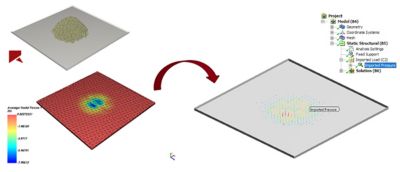

Exporting loads from Rocky DEM for static structural simulations

Physical prototyping involves a lot of time, cost and effort. As a result, it’s not conducive to competitive product launch cycles. So, engineers have been adopting high-fidelity simulation tools (like finite element analysis [FEM], computational fluid dynamics [CFD] and discrete element method [DEM]) to design products.

To design that bucket conveyor, engineers could couple Ansys Mechanical and Rocky DEM to simulate and optimize it virtually.

FEM and DEM Basics

Engineers use FEA software, like Mechanical, to perform structural simulations for the civil, automotive, aviation and other sectors.

Rocky DEM calculates the loads on a bucket excavator from the bulk material it is moving.

Static simulations solve for the equilibrium conditions and deformations of a structure under specified loads. For transient simulations, the equilibrium conditions account for both deformation and kinematic energies.

DEM is an integral tool to study particle dynamics. It handles bulk material like rocks, soil, powdered chemicals, food chips and pharmaceutical tablets.

DEM accounts for all of the forces acting on each particle within a bulk system. It then provides insight into how these materials would perform within a given component over a range of process conditions.

Rocky DEM can simulate systems with many particles that have complex shapes and accurate sizes. The tool is used across multiple industrial sectors, including:

- Mining

- Heavy machinery

- Agriculture

- Chemical

- Pharmaceutical

Coupling Ansys Workbench with Rocky DEM

During simulation, Rocky DEM tracks the loads on each node of a geometry mesh. These loads are then exported as a pressure field for further analysis with Mechanical. The FEA software then discretizes the geometry and solves for the equilibrium conditions.

By coupling structural analysis with Rocky DEM, engineers can simulate transient cases while incorporating geometry motion and time-varying loads on boundary elements.

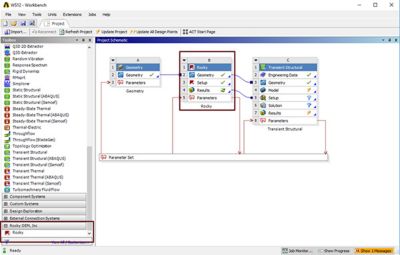

Rocky DEM is fully integrated into Ansys Workbench.

In addition, Rocky DEM is fully integrated into Ansys Workbench so it doesn’t require external software to couple it with Mechanical. This also enables engineers to easily apply design exploration tools for virtual parametric studies, optimizations, robustness analyses and response surface generation.

Rocky DEM can replicate complex motions within its UI, including combined motion and particle-induced free body motion with 6 degrees of freedom.

Solving Real-Life Problems

Many clients have coupled Ansys software with Rocky DEM to improve their equipment and processes.

For example, one of the largest producers of iron ore faced poor production efficiency whenever crushed ore jammed the moving screens at the base of its hoppers. This increased maintenance and downtime to clean the equipment.

A design of experiments within ANSYS Workbench generates a response surface.

Using Mechanical and Rocky DEM, the company accurately characterized the screen loads following their regular processes. Rocky DEM captured the broad size and shape distribution of the incoming ore.

This enabled the company to implement effective design changes to the equipment, such as optimizing the tilt angle, rotation speed, distance and profile of the roller disks. After these changes, production increased 11.4%, which saved the company $100 million in just over 3 months.

To learn more about Ansys Rocky, view for one of our 15-minute webinars.

Or get the latest on Rocky in our webinar: Ansys 2023 R1: Ansys Rocky What’s New.