-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

May 11, 2021

Motorizing the Bike You Love with Bimotal and Ansys Simulations

The Bimotal Elevate is a removable, lightweight and e-bike motor that mounts to your bike's disc brakes.

All your mountain biking friends are buying e-bikes, and, even though you are considering joining them, you have a problem: You like your current bike too much to trade it in. Your bike has just the right weight and feel, and you’ve been through a lot together. None of the e-bikes or retrofit kits available has the perfect combination of features.

Luckily for you, the Elevate portable electric motor assembly from Bimotal will soon be on the market. Designed using Ansys Motor-CAD simulation software obtained as part of the Ansys Startup Program, Elevate is a lightweight device that can be installed in seconds using a quick-connect cam lever on the brake rotor of the back wheel of your current bike. A throttle control on your handlebar lets you decide when to turn on the motor for a quick burst of power to help you get up that hill in front of you. And, if you are getting ready for a rocky downhill run and would like to reduce the unsprung weight, you can just as easily disconnect it and put it in your backpack for the ride down.

Toby Ricco, Founder and CEO of Bimotal

Elevate is the brainchild of Toby Ricco, Founder and CEO of Bimotal, and “Motor Expert” (that’s his official title) Chad Furey, an electrical engineer with a focus on motor design, who had worked together at Tesla a few years back. Jason Roesslein and Matt Rounds, also former colleagues of Ricco and Furey, joined the team in the summer of 2020. When Ricco mangled his knee in a skiing accident in 2018, he was worried that he might not be able to enjoy mountain biking again, because his knee lacked the power to push up some of the hills.

“I started looking for full e-bikes as well as e-bike retrofit systems and found that both were still super heavy, expensive and clunky,” Ricco says. “I wanted a way to put a motor on a bike that was super light and something I could take on and off. So that's how the system and company was born.”

Finding a Better Way to E-Bike

The knee took a long time to heal, which gave Ricco the space to look at e-bike design in a new way.

“It was literally me with an injured knee staring at my bike every evening after work for an hour,” Ricco says. “I thought, ‘There's got to be a better way.’ And this went on for months … I just kept looking.”

For reference, typical mid-drive e-bikes have the motor in the bottom bracket in front of the crankshaft where the pedals are located. For most speeds (anything above 5, maybe 8 mph), the motor is geared down to the user's cadence at the pedals and then geared back up through the bike chain and cogs mounted on the rear wheel hub. Thus, the motor is operating at a lower total motor-to-wheel gear ratio, which requires more motor torque and is inherently less efficient or heavier for the same power. Other common e-bikes are powered by hub motors which transfer torque directly to the wheel, usually with limited-to-no gear reduction, which again leads to a heavier motor for a given torque and efficiency at the wheel.

Bimotal says the Elevate motor and battery can be removed in 20 seconds.

“I kept thinking, ‘How can I get torque to the wheel?’" Ricco says. “And eventually it came to me: The brakes can take a lot of torque. A motor gearbox driving a wheel didn’t exist in the e-bike world at that time, even though that's how every single electric powered car does it."

Having settled upon the basic idea, the challenge was making it simple. In Ricco’s mind it had to be this easy: Fasten the Elevate motor to a bracket on the brake post mounts and start cycling.

Making the E-Bike Idea Work Through Simulation

With the idea of the Elevate motor established, and Bimotal launched as a company in July 2019, the real work began. While Ricco worked on the motor mount design, quick connect system and gearing to drive through a bike’s brake rotor, Furey got busy simulating every aspect of the battery-powered motor to make the Elevate system the lightest, quietest and most efficient, with the highest power density possible.

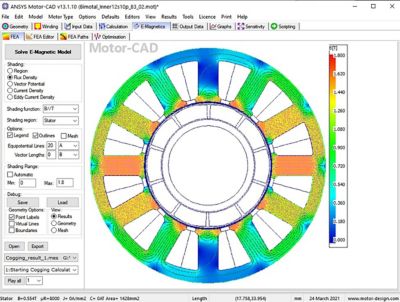

Bimotal uses a thermal model in Motor-CAD to understand the temperature rise in the motor under various operating conditions.

As a startup with very little funding, the design and engineering had to be done as economically as possible. “When you start looking around at simulation software and you ask Ansys if they have a better deal for startups, you quickly learn about the Ansys Startup Program,” Furey says. “We were excited that we could use Ansys software at such a low price.”

Soon Furey was using his own, well-established process of using MATLAB with custom scripts he wrote to automatically assess tens of thousands to a hundred thousand designs at a time, followed by Ansys Motor-CAD on the best candidates. This huge number of models piles up quickly with just a few tweaks to the design.

“I want to determine if the magnet should be this big or this big, or if the rotor should be this big or this big?” Furey says. “You take 10 magnet variations and 10 rotor variations and 10 thermal variations, and soon you're at 1,000 iterations. So the thing in motor design is that with 100 parameters to adjust, the number of iterations just explodes.”

Using this brute force approach, Furey can quickly assess the fundamental viability of all these combinations, and then take a closer look at the 10 or 15 most viable candidates using Motor-CAD.

“I refine the good candidates and use Motor-CAD to make sure everything's lining up nicely,” Furey says.

He uses a thermal model in Motor-CAD to get a good feel for the temperature rise in the motor under various operating conditions. The software generates efficiency maps that can help him determine the drive profile and the loss at key points in the motor’s design. Motor-CAD also helped with the decision to use surface permanent magnets or interior permanent magnets.

“Those are very simple things to try in Motor-CAD,” Furey says. “I can experiment to see ‘Hey, can I get the torque density up any higher?’"

Optimizing the System

Ricco designed one of the smallest cam lever connector systems available, with a clamping power of 1,000 Newtons of force to make sure the Elevate package stays on the bike on rough rides. You can see how easy it is to connect the motor here.

In the end, even though the Elevate motor is a small system that you can hold in one hand, there was a lot of engineering to do. “It's a whole system optimization challenge,” Ricco says. “How much power do we really want? How much does a bike need? And then, basically, how much heat do we need to reject or can we reject? How small can we make the heat sink? How small can we make the motor and still have this really punchy system?"

Motor-CAD had a part to play in answering all these questions and more. The resulting Elevate motor weighs only two pounds and can generate up to 750 W of power. With the help of Ansys simulation, they stayed true to their motto, helping people to “Keep Riding the Bike You Love.” Bimotal will start delivering Elevate in the second quarter of 2021, after which they will focus on micro electric powertrain design bikes, scooters and other forms of last-mile transportation.

“In our mission to reduce barriers to car-free mobility, we are en route to becoming motor, gearbox, battery and electronics experts,” Ricco says. “The motor and gearbox optimizations are made faster and more efficient with the help of Ansys tools."

Learn more about the Ansys Startup Program.