-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

November 4, 2020

How to Create a Digital Twin

Credit: Scott Haefner, U.S. Geological Survey. Public domain.

When Joseph Strauss, Leon Moisseiff and Charles Alton Ellis designed San Francisco’s Golden Gate Bridge in 1917, the engineers likely knew it would become a world-famous bridge. After all, when it opened in 1937, it was the longest and tallest suspension bridge in the world. They would have had no way of imagining that other engineers would one day create a digital twin of the bridge, but that’s what engineers at Ozen Engineering have done with the help of Ansys software.

Ozen Engineering is an Ansys certified elite channel partner. When the company wanted to create a demonstration of how to use reduced-order modeling (ROM) in Ansys Twin Builder, they didn’t have to look far for an example. The Golden Gate Bridge is less than 50 miles north of the company’s Sunnyvale, Calif., headquarters.

“We wanted something people could recognize and easily understand,” says Vice President of Ozen Engineering Chris Cowan. “The Golden Gate Bridge is one of the most photographed bridges in the world. Everyone knows what it looks like.”

Cowan, with Ozen application engineers Ahmed Elghandour and Anchong “Stephen” Liu, set out to create a model that would capture the wind pressure on the bridge, which would be used in Twin Builder to calculate forces on the bridge structures as the wind direction or velocity changed.

By the Numbers: The Golden Gate Bridge

- 8,980-ft. long

- 746-ft. high

- 90-ft. wide

- 4,200 ft. is the longest span

- 4 years to construct

- 372-ft deep water at the center of the channel

- 1.2 million rivets hold the bridge’s two towers together

- > $35 million in construction (about $562 million today)

Five Steps to Create a Digital Twin of the Golden Gate Bridge

Whether creating a digital version of an iconic bridge or any other structure or system, the Ansys digital twin workflow is the same. You need a clean geometry to mesh and solve, then you create a reduced-order model (ROM) and analyze that ROM through Twin Builder.

1. Geometry

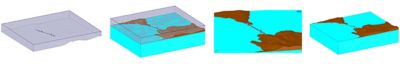

Ozen’s first challenge was creating a geometry of not just the bridge, but the surrounding landscape. The company used an open geometry from the GrabCAD community and merged it with the area’s topographical geometry that was obtained via an Ansys ACT tool called Topographic STL maker ACT. ACT is an easy-to-use development environment that uses XML and IronPython programming languages to enable non-expert users to create custom apps for advanced workflows.

“Part of problem was the geometry. It was not built for simulation,” says Cowan. “The clean-up was a job for the Ansys SpaceClaim 3D modeler, and it worked well.”

2. Meshing

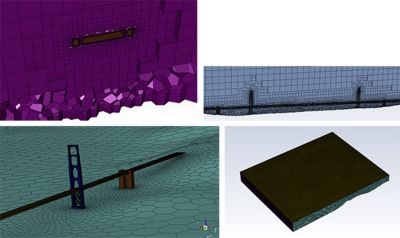

In addition to demonstrating how to create a digital twin, Ozen Engineering wanted to show off Ansys’ Mosaic Meshing technology, which automatically connects different types of meshes with general polyhedral elements. The new Poly-Hexcore feature in Ansys Fluent uses this technology to fill the bulk region with octree hexes, maintain a high-quality, layered polyprism mesh in the boundary layer and conformally connecting the two meshes with general polyhedral elements.

“The size of the bridge requires a complex mesh in order to capture all the different scales in a simulation,” Cowan says. “Thanks to Ansys Fluent meshing, that was straightforward and efficient.”

Just how big of a mesh are we talking? The fluid model dimensions were 7,670 m x 6,150 m x 720 m3, which required 4.8 million Poly-Hexcore elements and 14.5 million nodes.

3. Solving

“Computational fluid dynamics (CFD) is a nonlinear problem by nature, and it could be complicated by solving it as simple laminar or more complex turbulent problem,” says Elghandour. “The model we’re using has a polyhedral hexcore mesh, which is one of newest technologies in meshing.”

To show the accuracy and speed of solving Poly-Hexcore mesh, Ozen decided to solve a turbulent model (K-Epsilon, realizable).

4. Building a ROM for a Digital Twin

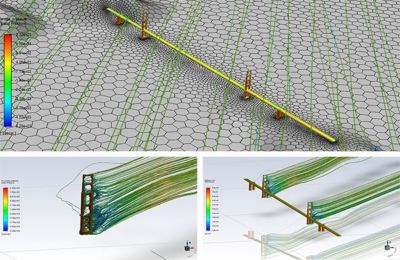

The capabilities to set up a ROM are built into Fluent and can be generated in Ansys DesignXplorer, an integrated Ansys Workbench application for exploring, understanding and optimizing your design. Ozen Engineering set a maximum wind velocity range and multiple wind direction components, then created a study out of that to populate and build the ROM.

A functional mockup (FMU) was created for Twin Builder using a Design of Experiments (DOE) study based on wind vectors. “We studied wind direction along with the minimum and maximum range of typical velocity conditions,” says Elghandour.

5. Implementing the ROM via Twin Builder

Once the simulations were completed, Ozen engineers extracted the ROM file for use in Twin Builder to predict results when different inputs are used.

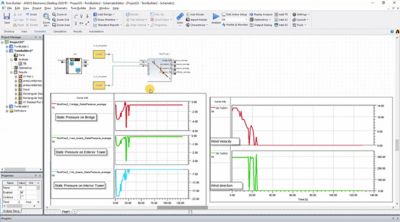

Ozen Engineering created a data connector in Twin Builder that uses a Python script to reach out over HTTP to the National Oceanic and Atmospheric Administration website to obtain live, updated windspeed and direction data. That data is tied into the Twin Builder project to be evaluated through the ROM.

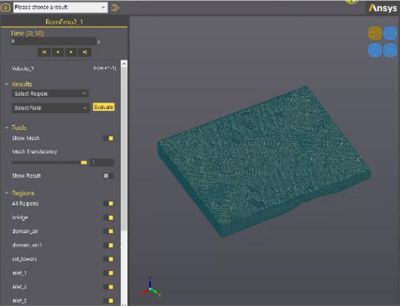

“You can pick any time step during the simulation and evaluate different results,” Liu says. “The script reads the past two-hours of data from a website and keeps capturing it for the next two hours, showing the results.”

Data is presented in a chart format, and the ROM viewer provides a visual display of the results data at various time steps. For example, pressure distribution on the bridge and towers can be visualized in near real time. Live data is sent every 15 seconds, but only changes every five minutes because the website data points are updated every five minutes.

“The beauty of this digital twin is that it’s practical, but not in too much detail, so it’s easy to understand by most people,” says Elghandour. “At the same time, it’s a complicated CFD problem.”

“The team at Ozen Engineering recognizes the power that real-time simulation brings to predictive maintenance and operations planning,” says Cowan. “We continue to develop multiphysics digital twins combined with physical prototype hardware to demonstrate the versatile capabilities.”

The projects are intended to be portable, simple to understand and easy to validate using handheld equipment. Their inventory of prototypes includes:

- A wind tunnel fluid dynamics application that predicts lift on an airfoil.

- A bi-metallic strip thermal-electric-structural application that predicts deformation, electric potential, and Joule heating temperature as a function of driving current.

- A magnetostatic inductor coil application that predicts magnetic field distribution.

Ozen Engineering is also building advanced digital twin models for predictive maintenance of unmanned aerial vehicle (UAV) components through research grants funded by the US government.

For more information on creating digital twins, download the white paper: Digital Twins: Making the Vision Achievable.