-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

March 20, 2020

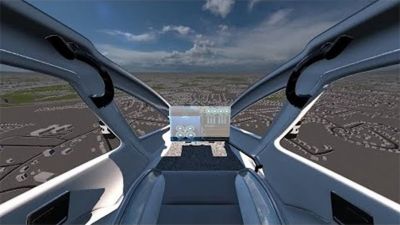

The Remarkable HMIs of Futuristic Cockpit Designs

To get an idea of what futuristic cockpit designs will look like, just take a peek at the digital dashboards of today’s most advanced automobiles.

In place of the physical dials, gauges and push buttons there are sleek video screens that display more information than previously possible.

The futuristic cockpit designs will look a lot like modern automobile dashboards.

Speed in miles- or kilometers-per-hour might be displayed in large numerals instead of a needle position on a gauge. A powertrain schematic might show how the gasoline-powered engine is recharging the batteries of a hybrid vehicle. And the infotainment system might have a touch screen that can switch the satellite radio station.

Similarly, the cockpit of the future will substitute analog elements for digital ones, resulting in a cleaner aesthetic that utilizes a human-machine interface (HMI) of touchscreens, colorful interactors and indicators. The technology will also generate more data for the airlines and employ more automation for consistent flights.

Aircraft OEMs need to provide the safest and best experience for airline pilots. In the face of rising competition for aircraft purchases and the need to lower the costs to train pilots, updating the cockpit could be one of the best solutions.

It is now up to engineers and HMI specialists to ensure that any new design meets usability, access, safety and reliability standards so pilots can fly aircraft with less effort than ever. For instance, they will need to ensure the system avoids cognitive overloads and mode confusion — when the pilot might need to overrule the automation. To optimize the cockpit to these considerations, the specialists need to test it with pilots at various levels of expertise.

What Challenges Do Cockpit Designers Face?

Similar to a dashboard, redesigned cockpits must be optimized for smooth pilot interaction, while avoiding information overload.

However, the design is more complex, with more information and controls than a car’s digital dashboard.

A simulation of aircraft controls

Critical questions that arise when designing futuristic cockpits include:

- Will the design meet certification and safety standards?

- Are the most frequently used controls placed conveniently?

- How to avoid mode confusion (where the aircraft’s assessments are out of sync with the pilot)?

- Are multitouch screens convenient to use during turbulence and critical scenarios?

- Are the layout, interactors and indicators designed to operate within the pilot’s cognitive threshold?

- Is it simple for pilots to access the most crucial controls in the event of an emergency?

- Are mission-critical messages and alerts easily available and understandable for pilots?

- Can pilots easily view the right level of information during a flight in all weather conditions?

Simulations can play a big part in answering these design questions.

How Can Simulation Be Used Effectively in Cockpit Design?

Building physical prototypes of potential cockpit configurations, for human testing, is a time-consuming and expensive task. These prototypes are often built at the end of the design cycle where problems are complex and costly to fix.

Simulation can reduce the time and costs by automatically generating certified code for aircraft controls and by offering a virtual environment for prototype and safety testing. The code and simulation can also be easily reconfigured when components need to be relocated or modified for accessibility.

As result, these virtual prototypes can be created early in the development cycle so engineers can discover and fix issues when it is cost effective to do so.

Virtual models being used to prototype a control layout.

Building the virtual prototype starts with a code generator. It automatically compiles embedded controls and HMI codes that meet aircraft certification standards. The code generation is more reliable than human-written code — an important consideration for safety-critical applications. Ansys SCADE and Ansys SCADE Display solutions are the best options for aerospace engineers interested in embedded code generation.

From there, a pair of virtual reality (VR) googles can turn any space into a virtual cockpit. The engineer needs to import the cockpit geometry and then define the location of instruments, controls, displays and interactors. Then by looking into the goggles, the pilot can see the instruments and controls —they can even interact with them as if they were real components. The pilot can then make judgments as to:

- The placement of readouts and interactors

- The visibility of outputs when the sun’s glare falls upon instrument panels

- The amount of information that is calling for their attention at once

Getting Results from Virtual Testing

Based on the feedback from the simulated environment, engineers can automatically detect the pilot’s actions through:

- Finger tracking

- Haptic feedback (also known as kinaesthetic communication or 3D touch)

- Human factors analysis

A virtual reality device that tracks fingers and provides vibrations to simulate tactile interactions.

Finger tracking can also help engineers evaluate the cockpit elements associated with a given task. For instance, using a critical path analysis they can assess the pilot’s ability to complete a procedure and the minimum time needed to complete it.

Haptic feedback is necessary to let the pilot know that a button is pushed and actions are carried out successfully. It overcomes the lack of actual physical feedback. To achieve this, engineers can equip the virtual HMI prototype to provide vibro-tactile sensations, through a controller or glove. This is more effective than beeps to indicate interactions with virtual components.

Ansys VRXPERIENCE HMI simulation software is widely used for virtual testing. It can put pilots of various experience levels in the loop with the HMI to ensure the speed, accuracy, cost-effectiveness and safety of the design.

How to Simulate Cockpit Lighting Conditions

Being able to see the displays and controls of the cockpit HMI under all conditions is another important safety factor. Glare, reflection and display washout can all distract the pilot from clearly seeing the HMI.

Ansys Speos and Ansys VRXPERIENCE can evaluate the cockpit design under various lighting conditions.

Ansys Speos physics-based lighting simulation software can evaluate these factors along with all ambient lighting conditions. It can also simulate the behavior of the human eye under a wide spectrum of lighting conditions to ensure the HMI is visible no matter the weather or time of day.

Any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans such as Ansys, Ansys SCADE, Ansys Speos and Ansys VRXPERIENCE are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries.